Concentration and recovery device for industrial electroplating wastewater

A recovery device and electroplating wastewater technology, which is applied in metallurgical wastewater treatment, electrolysis process, electrolysis components, etc., can solve the problems of aquatic animal system hazards, high cost, and affecting human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

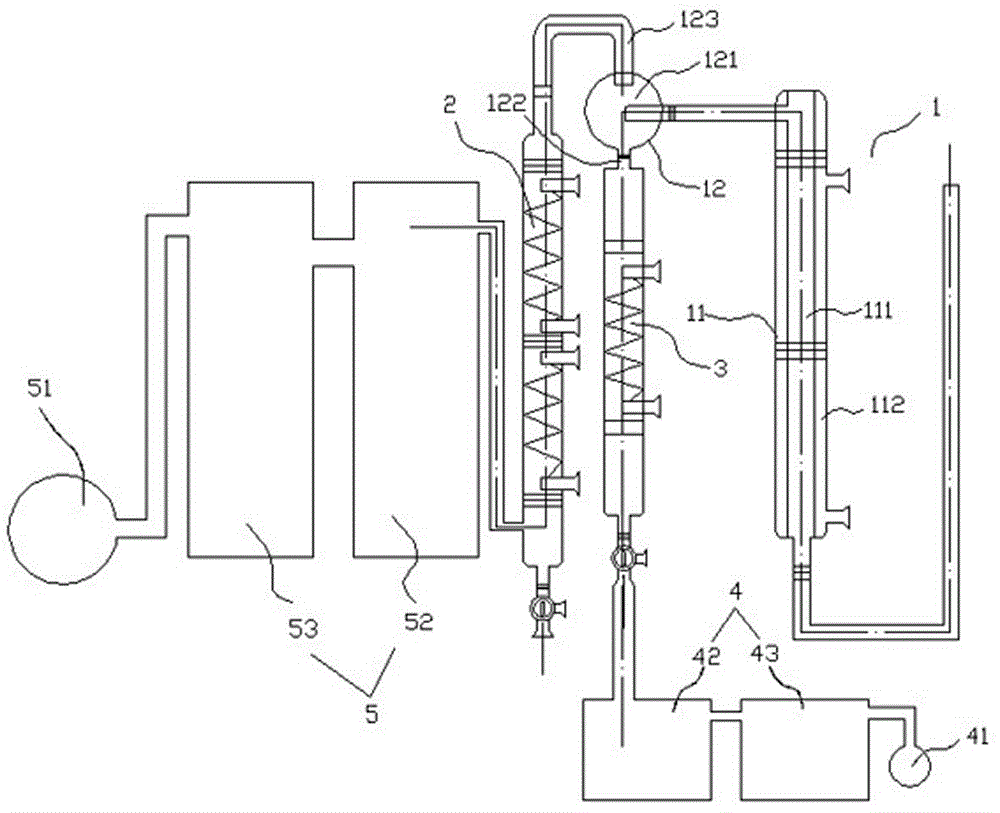

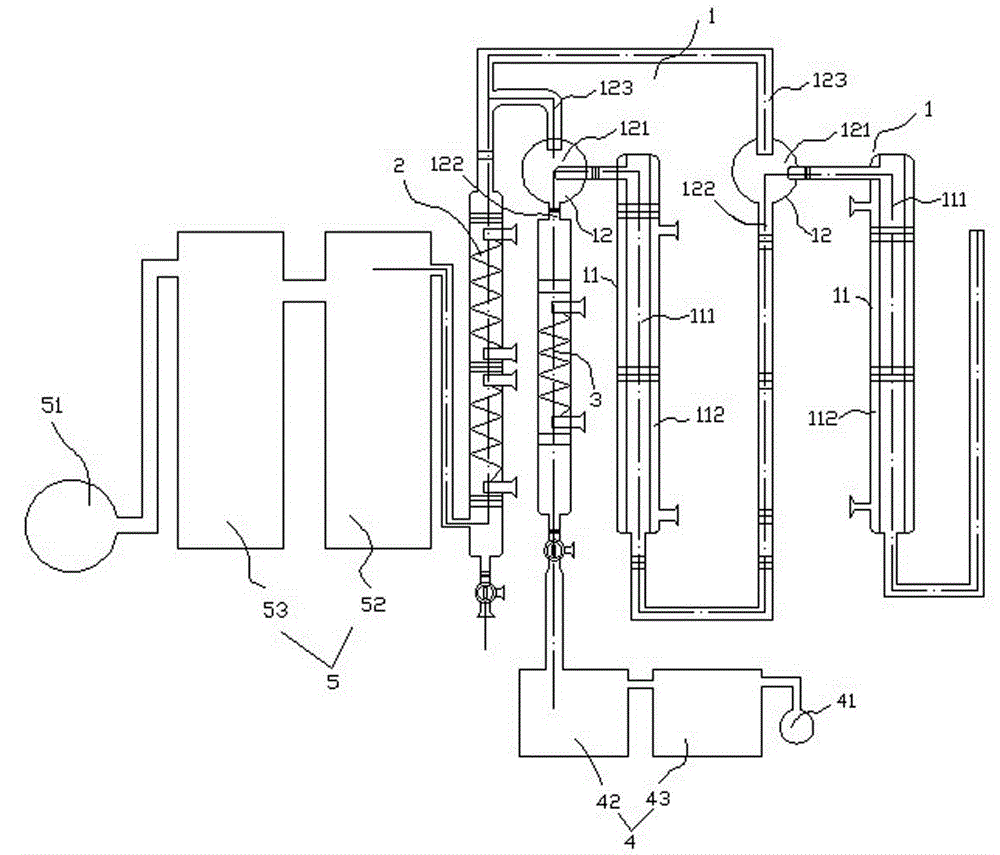

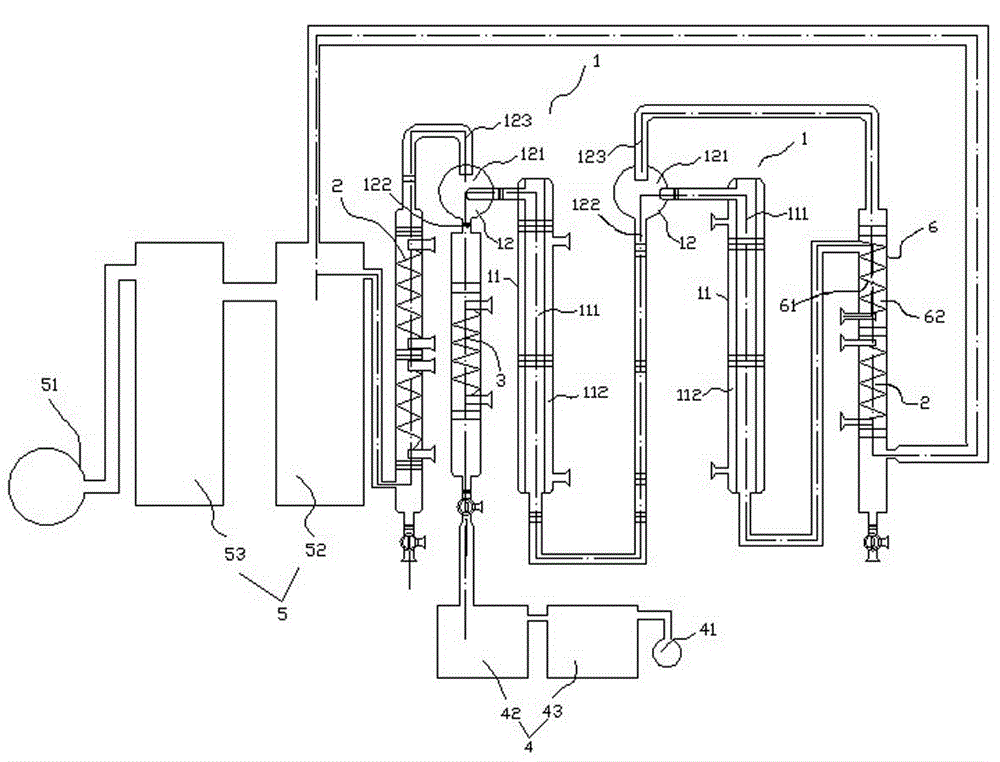

[0028] Such as figure 2 As shown, it is the second embodiment of the present invention. The whole device includes a heating separation system, a water condenser 2, a liquid material condenser 3, a liquid material collection tank 4 and a distilled water collection tank 5. The heating separation system includes at least one stage of separation devices 1 , and two stages of separation devices 1 are used in this embodiment. In practice, three or more stages can be set as required. Each stage separation device 1 is composed of a straight pipe evaporator 11 and a cyclone separator 12 . The straight tube evaporator 11 includes a straight tube inner passage 111 and a straight tube outer passage 112, wherein the straight tube inner passage 111 is a waste liquid pipeline, and the straight tube outer passage 112 is a circulation channel for a heating medium. The outlet of the waste liquid pipeline in the separation device 1 of the same level goes directly into a separation chamber 121 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com