Separating device for kiln flue gas

A separation device and flue gas technology, which is applied in the direction of combination device, separation method, and dispersed particle separation, can solve the problems of polluted air, poor treatment effect, and health hazards, and achieve the goal of improving purification effect, reducing replacement, and reducing pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

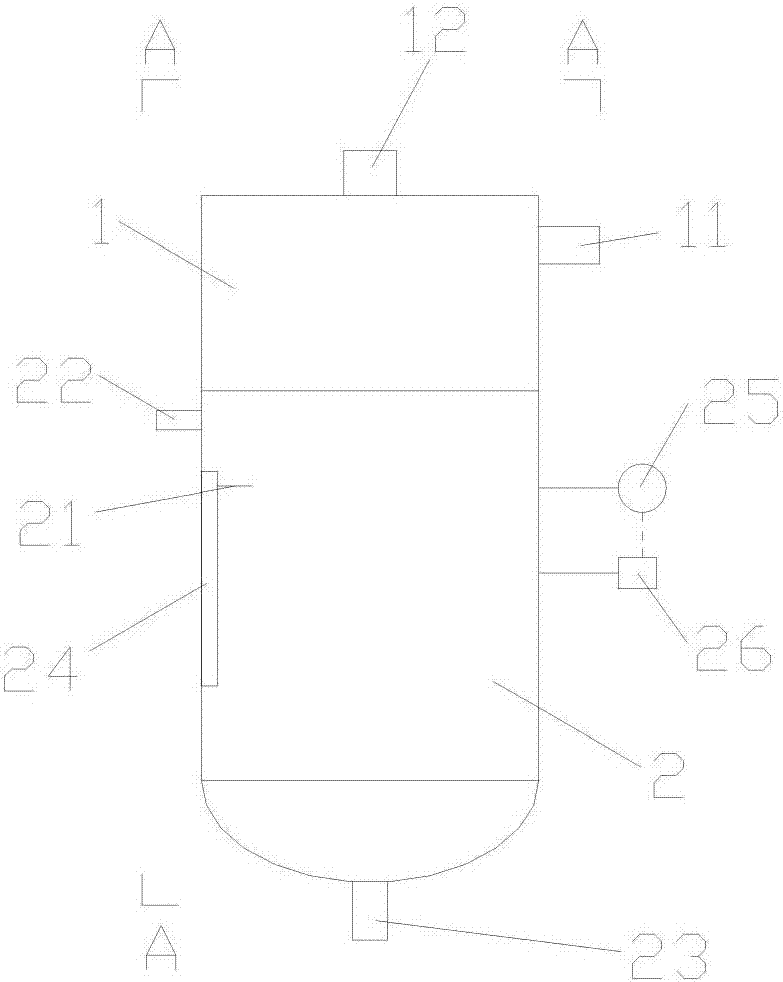

[0029] A separation device for kiln flue gas, such as figure 1 As shown, the separation device includes a cylinder, the cylinder includes an upper cylinder 1 and a lower cylinder 2, and the upper cylinder and the lower cylinder are snap-connected to form a closed cylinder cavity, and the upper cylinder and the lower cylinder form a closed cylinder cavity. The body snap connection is for easy disassembly and subsequent cleaning and maintenance.

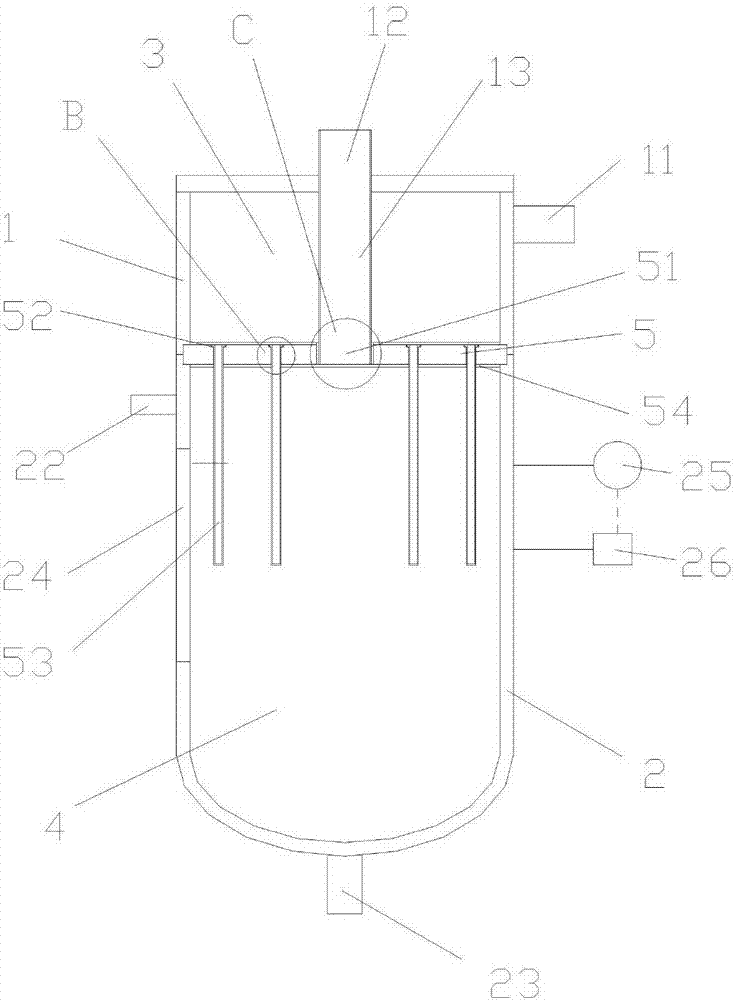

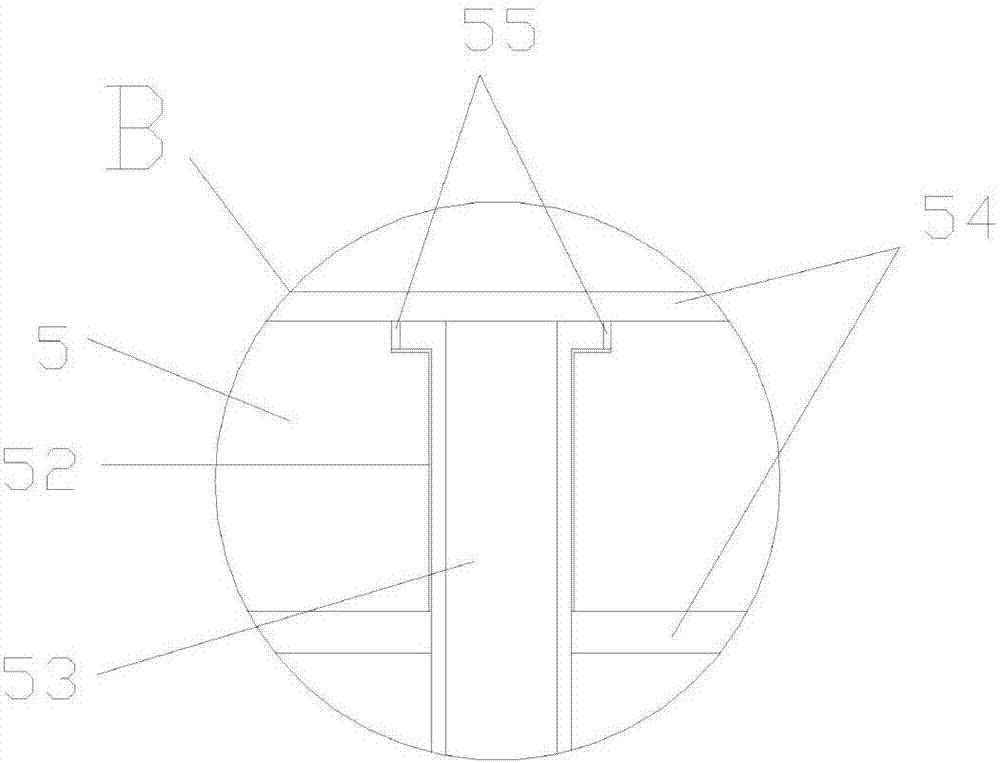

[0030] like figure 2 As shown in the figure, at the junction of the upper cylinder and the lower cylinder, there is a partition plate 5 that separates the cylinder cavity into the upper cavity 3 and the lower cavity 4; the side wall of the upper cylinder 1 is provided with The flue gas inlet 11 communicated with the upper cavity 2, the top of the upper cylinder is provided with a first clean gas outlet 12; the side wall of the lower cylinder 2 is provided with a rated liquid level line 21, the side wall of the lower cylinder is provi...

Embodiment 2

[0035] In this embodiment, on the basis of Embodiment 1, a liquid level gauge 25 and a liquid level alarm device 26 connected to the liquid level gauge 25 are added on the lower cylinder. It makes its detection more automatic, saving time and effort.

Embodiment 3

[0037] In this embodiment, a further improvement is made on the basis of Embodiment 1 or 2. The bottom of the lower cylinder body 2 is elliptical arc shape, and the sewage outlet 23 is set at the lowest part of the bottom. It can prevent the dirty liquid from depositing on the bottom of the lower cylinder and block the sewage outlet, which is beneficial to the sewage discharge from the sewage outlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com