Pressure-sensitive adhesive composition for optical members and pressure-sensitive adhesive tape for optical members

A technology of optical components and adhesives, applied in the direction of adhesive types, ester copolymer adhesives, film/sheet adhesives, etc., can solve the problems of adhesive properties and heat resistance that cannot be said to be sufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

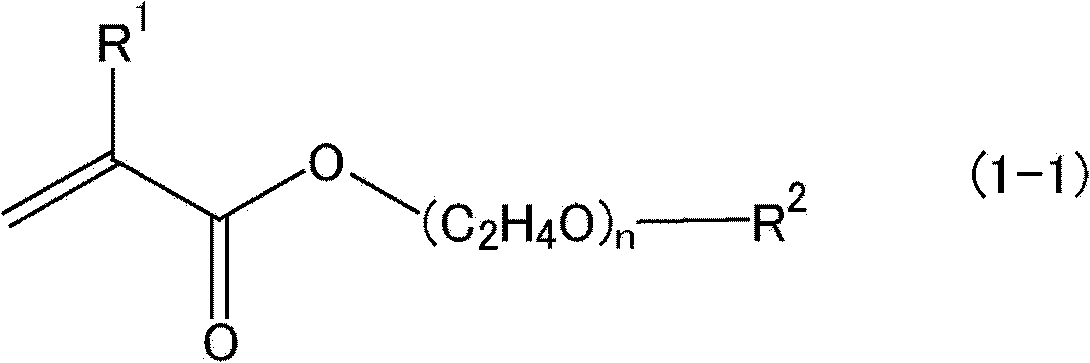

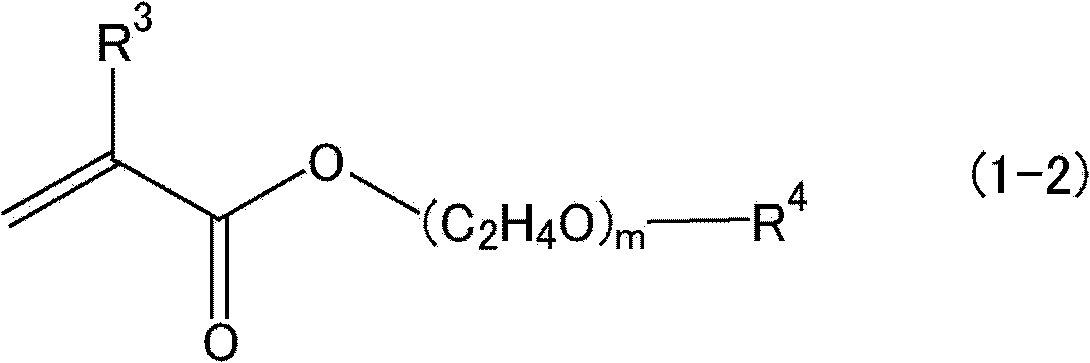

Method used

Image

Examples

Embodiment 1-1

[0131] (1) Manufacture of acrylic copolymer

[0132] In a reactor equipped with a thermometer, a stirrer, and a cooling pipe, add 44.5 parts by weight of 2-ethylhexyl acrylate, 30 parts by weight of isobornyl acrylate, 0.5 parts by weight of acrylic acid, 25 parts by weight of 2-hydroxyethyl acrylate, and relative After replacing 100 parts by weight of ethyl acetate with 100 parts by weight of these monomers with nitrogen, the reactor was heated and reflux was started. After 30 minutes, with respect to 100 parts by weight of the monomer, 0.2 parts by weight of tert-hexyl peroxypivalate as a polymerization initiator was diluted with 5 parts by weight of ethyl acetate, and the mixture was dripped over 2 hours in the above-mentioned reactor. The resulting polymerization initiator solution was added. Thereafter, at 70° C., it was refluxed for 8 hours from the addition of the polymerization initiator to obtain an acrylic copolymer solution having a solid content of 50%.

[0133]W...

Embodiment 1-2~1-5

[0138] (Examples 1-2 to 1-5, Comparative Examples 1-1 to 1-3)

[0139] By changing the monomer composition of the acrylic copolymer, except that the acrylic copolymer having the ratio (% by weight) of the constituent units shown in Table 1 was obtained, the same operation as in Example 1-1 was performed to obtain Double-sided adhesive tape for optical members bonded with release polyethylene terephthalate film.

Embodiment 2-1

[0141] (1) Manufacture of acrylic copolymer

[0142] In a reactor equipped with a thermometer, a stirrer, and a cooling pipe, add 59.5 parts by weight of 2-ethylhexyl acrylate, 15 parts by weight of isobornyl acrylate, 0.5 parts by weight of acrylic acid, and 25 parts by weight of N-vinylpyrrolidone. After replacing 100 parts by weight of ethyl acetate with 100 parts by weight of monomers by bubbling with nitrogen, the temperature of the reactor was set at 70° C. under a nitrogen stream. Next, 0.2 parts by weight of tert-hexylperoxypivalate as a polymerization initiator was diluted with 5 parts by weight of ethyl acetate with respect to 100 parts by weight of monomers, and the resulting mixture was added dropwise in the reactor over 2 hours. The resulting polymerization initiator solution. During the reaction, the temperature was controlled by heating and cooling so as to keep the reaction temperature at 70°C. The reaction was performed at 70° C. until 8 hours after the star...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com