Casting process for high-explosive primer

A process method and technology for detonating tools, which are applied in the directions of blasting cylinders, weapon accessories, offensive equipment, etc., can solve the problems of high cost, low production efficiency, and high risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

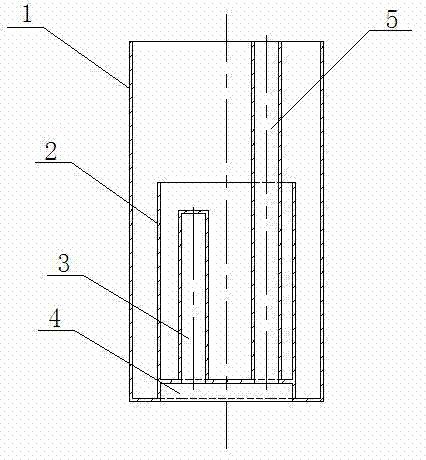

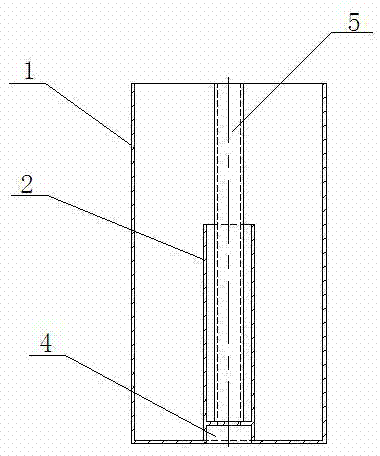

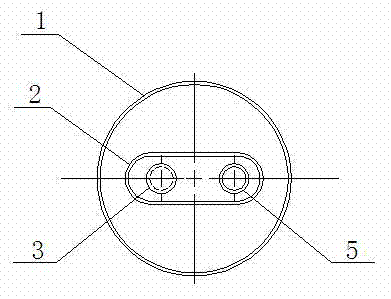

[0020] The technical solution of the present invention will be described in further detail below through embodiments and in conjunction with the accompanying drawings.

[0021] like figure 1 , 2 , Shown in 3, high-explosive detonator injection process method of the present invention, it specifically comprises the following processing steps:

[0022] (1) Make the shell of the detonator. The shell is one-time injection molding. It has an outer shell 1. The upper end of the outer shell is open, and the lower end is closed by the bottom plate. A notch is opened in the center of the bottom plate. Compatible positioning plate 4, the upper part of the positioning plate stretches into the housing, the positioning plate is provided with two functional holes, and two positioning tubes are arranged opposite the two functional holes in the housing, which are respectively the first positioning tube 3 and the second positioning tube. Positioning tube 5; an inner housing 2 is arranged insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com