Antique paint electroplating process

An electroplating process and process technology, applied in the field of Qinggujia lacquer electroplating process, can solve the problems of poor corrosion resistance of the electroplating layer, difficult to achieve the effect of antique, and the electroplating layer is easily corroded, and achieves high corrosion resistance, bright appearance and thickness. Even and moderate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

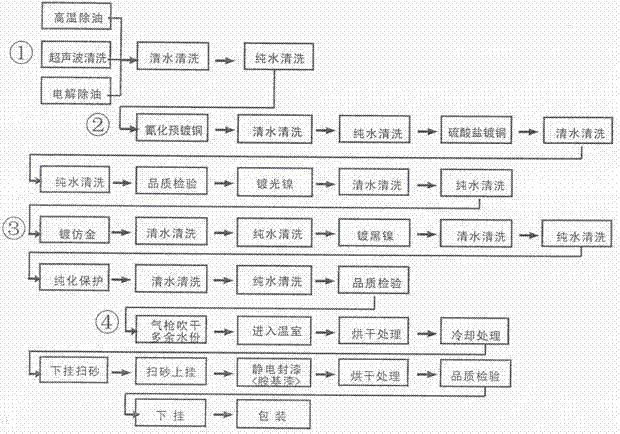

[0027] refer to figure 1 , propose an embodiment of a kind of green ancient paint electroplating process of the present invention, the present invention adopts the technique of rack plating, comprises the following steps: A, product cleaning treatment; B, bottom treatment; C, middle layer treatment; D, baking Dry sweeping and electrostatic sealing paint protection treatment. Steps 1, 2, 3, and 4 in the figure correspond one-to-one to steps A, B, C, and D in the above steps.

[0028] A. Product cleaning treatment: Carry out high-temperature degreasing, ultrasonic cleaning, electrolytic degreasing, and then clean water cleaning and pure water cleaning in sequence. The specific process is as follows:

[0029] First hang the products to be processed, use the hangers to hang the products to be processed and put them on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com