Process for producing acetone and butanol by biomass fermentation and pervaporation membrane coupling

A technology of pervaporation membrane and biomass fermentation, which is applied in the field of biomass fermentation-pervaporation membrane coupling production of acetone butanol, can solve problems such as phase separation of acetone butanol solvent and the like, so as to reduce production cost, save energy and save energy. Water consumption, the effect of reducing the inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

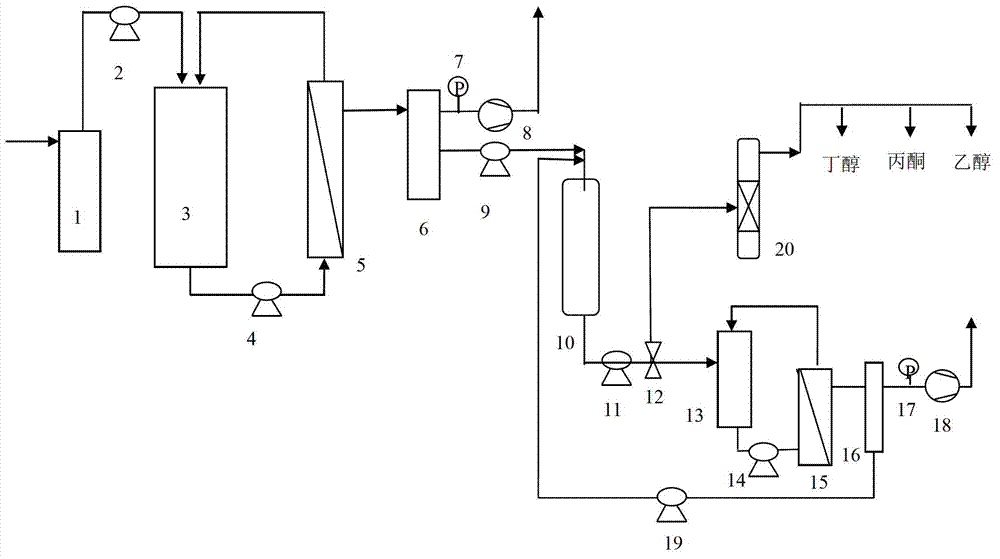

[0022] Example 1 A process for producing acetone butanol by a corn stalk fermentation-pervaporation coupling process

[0023] Corn stalks are treated with steam explosion, acid hydrolysis, and enzyme hydrolysis to make a slurry into the feed tank 1, turn on the feed pump 2 and enter the fermentation tank 3, and ferment at 37°C for 72 hours after being inoculated with microorganisms. When the solvent concentration is detected to reach 18g / L, the feed pump 4 is turned on, and the fermentation liquid is transported into the pervaporation-preferential alcohol-permeable membrane module 5. The pervaporation module is composed of two plate-and-frame pervaporation-preferential alcohol-permeable membrane separators connected in series. The pervaporation membrane used is an organic-inorganic hybrid membrane (PDMS-Silicalite-1). Simultaneously, open vacuum pump 8, vacuum gauge 7 vacuum degree maintains on 500Pa, and permeate is collected by condenser 6, and the total concentration of ace...

Embodiment 2

[0025] Embodiment 2 A kind of technology of corn flour fermentation-pervaporation coupled process to produce acetone butanol

[0026]Prepare the medium with corn flour as raw material, cook and gelatinize at 121°C for 90 minutes to obtain the corn flour medium, enter the feed tank 1, turn on the feed pump 2 and enter the fermenter 3, inoculate the microorganisms and ferment at 37°C for 60 hours, when When the total solvent concentration in the liquid phase in the tank is detected to reach 20g / L, the feed pump 4 is turned on, and the fermentation liquid is transported into the pervaporation preferential alcohol permeation membrane module 5, which is composed of a hollow fiber pervaporation preferential alcohol permeation membrane separator , the selected pervaporation membrane is the inorganic membrane Silicalite-1 or ZSM-5. Simultaneously, open vacuum pump 9, vacuum gauge 8 vacuum degree maintains on 500Pa, and permeate is collected by condenser 6, and the total concentration ...

Embodiment 3

[0027] This example realizes the semi-continuous fermentation of corn flour to produce acetone butanol, which not only greatly reduces the inhibitory effect of the acetone butanol solvent produced by fermentation on microbial cells, but also makes full use of the The phase separation property of high-concentration permeate can effectively reduce the energy consumption of the concentration process, and increase the production intensity of butanol compared with the traditional batch fermentation-distillation process. Example 3 A process for the production of acetone butanol by a continuous fermentation-pervaporation coupling process of corn stalks

[0028] Corn stalks are treated with steam explosion, acid hydrolysis, and enzyme hydrolysis to make a slurry into the feed tank 1, turn on the feed pump 2 and enter the fermentation tank 3, and ferment at 37°C for 20 hours after being inoculated with microorganisms. When the solvent concentration is detected to reach 5g / L, the feed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com