Degradable poly-methyl ethylene carbonate base composite material and preparation method thereof

A technology of polymethylethylene carbonate and composite materials, which is applied in the field of degradable polymethylethylene carbonate-based composite materials and its preparation, and can solve the problems of no way to prepare films, increase industrial costs, and limit the scope of application , to achieve the effect of good Vicat softening point, low cost and wide application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

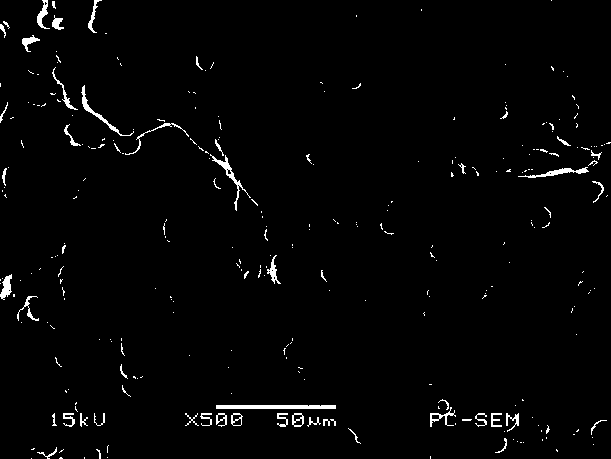

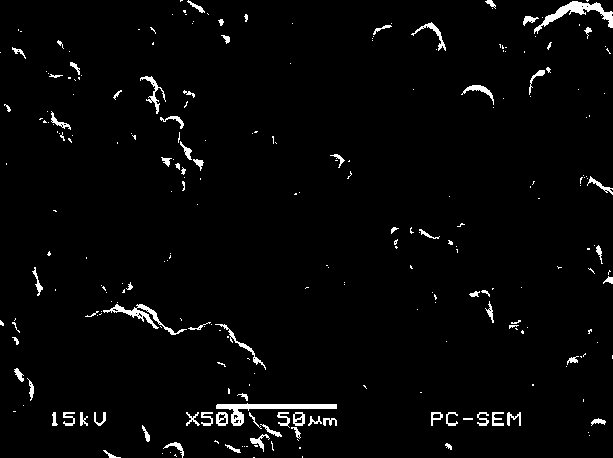

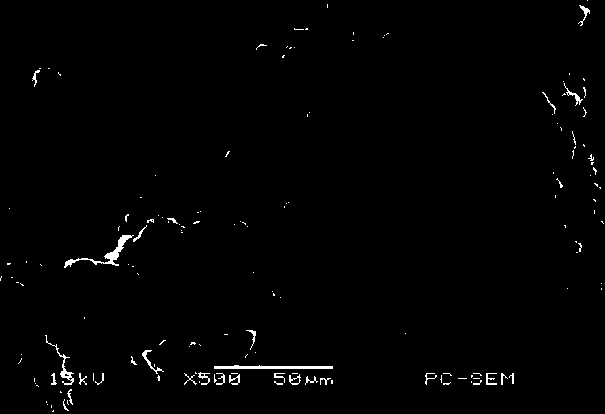

Image

Examples

Embodiment 1

[0030] Add 1000mL deionized water and 100g polyvinyl alcohol into the beaker, raise the temperature to 90°C and keep stirring with a mechanical stirrer. After the polyvinyl alcohol is completely dissolved, lower the temperature of the system to room temperature and then add 30mL of the solution with a mass concentration of 36 %-40% formaldehyde solution and 90mL hydrochloric acid solution with a mass concentration of 36%-38% were added to the beaker and stirred evenly. Then heat the temperature to 65°C and keep the temperature constant for 4 hours. After the product is taken out, it is cut into pieces with scissors, then washed with deionized water, and then a certain amount of sodium hydroxide solution is added to adjust the pH value of the material to around 7, and then the The material was dried in a blast oven at 80°C for 24 hours, and placed in a well-sealed desiccator for later use. The acetalization degree of polyvinyl formal is shown in Table 1 by proton nuclear magnet...

Embodiment 2

[0032] Add 1000mL deionized water and 100g polyvinyl alcohol into the beaker, heat it to 90°C with a magnetic stirrer and keep stirring with a mechanical stirrer. %-40% formaldehyde solution and 90mL hydrochloric acid solution with a mass concentration of 36%-38% were added to the beaker and stirred evenly. Then heat the temperature to 65°C, keep the temperature for 4 hours, then take out the product, cut it into pieces with scissors, then wash it with deionized water, add a certain amount of sodium hydroxide solution to adjust the pH value of the material to around 7, and then The material was dried in a blast oven at 80°C for 24 hours, and placed in a well-sealed desiccator for later use. The degree of acetalization of polyvinyl formal was tested by hydrogen nuclear magnetic resonance spectroscopy, and the results are shown in Table 1.

Embodiment 3

[0034]Add 1000mL of deionized water and 100g of polyvinyl alcohol into the beaker, heat it to 90°C with a magnetic stirrer and keep stirring with a mechanical stirrer. After the polyvinyl alcohol is completely dissolved, lower the temperature to room temperature and then add 100mL of polyvinyl alcohol with a mass concentration of 36 %-40% formaldehyde solution and 90mL hydrochloric acid solution with a mass concentration of 36%-38% were added to the beaker and stirred evenly. Then heat the temperature to 60°C and keep the temperature constant for four hours, then take out the product, cut it into pieces with scissors, wash it with deionized water, add a certain amount of sodium hydroxide solution to adjust the pH value of the material to around 7, and then The material was dried in a blast oven at 80°C for 24 hours, and placed in a well-sealed desiccator for later use. The degree of acetalization of polyvinyl formal was tested by hydrogen nuclear magnetic resonance spectroscop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com