Special active carbon injection control system for purifying flue gas from refuse incineration

A flue gas purification and waste incineration technology, which is applied in the field of waste incineration flue gas purification system, can solve the problems of inability to guarantee effective removal rate, poor feeding accuracy, and easy system failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

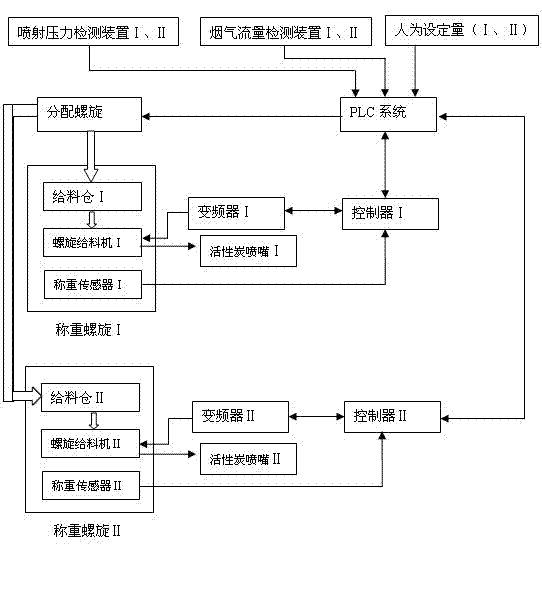

[0009] See figure 1 , which includes a distribution screw, two flue gas purification devices, and a PLC system, and the two flue gas evolution devices are equipped with a weighing screw, a frequency converter, a controller, and a flue gas flow detection device , injection pressure detection device, activated carbon nozzle, weighing screw specifically includes feeding bin, screw feeder, weighing sensor, and the screw feeder leads to the corresponding activated carbon nozzle. The PLC system is respectively connected to each flue gas flow detection device, The output end of the injection pressure detection device, the PLC system is bidirectionally connected to each controller, each controller is bidirectionally connected to the corresponding inverter, the inverter control is connected to the corresponding screw feeder, and the output end of the load cell is connected to the corresponding The controller and the PLC system are connected to the distributing auger, and the distributi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com