Brush carrier plate for automobile radiator fan motor

A technology for automotive radiators and fan motors, which is applied to electrical components, electromechanical devices, and electric components. It can solve the problems of multiple brush holder board specifications, affecting motor performance, and multiple wiring, and achieves avoiding cluttered wiring harnesses, compact structure, and easy wiring. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below through specific examples.

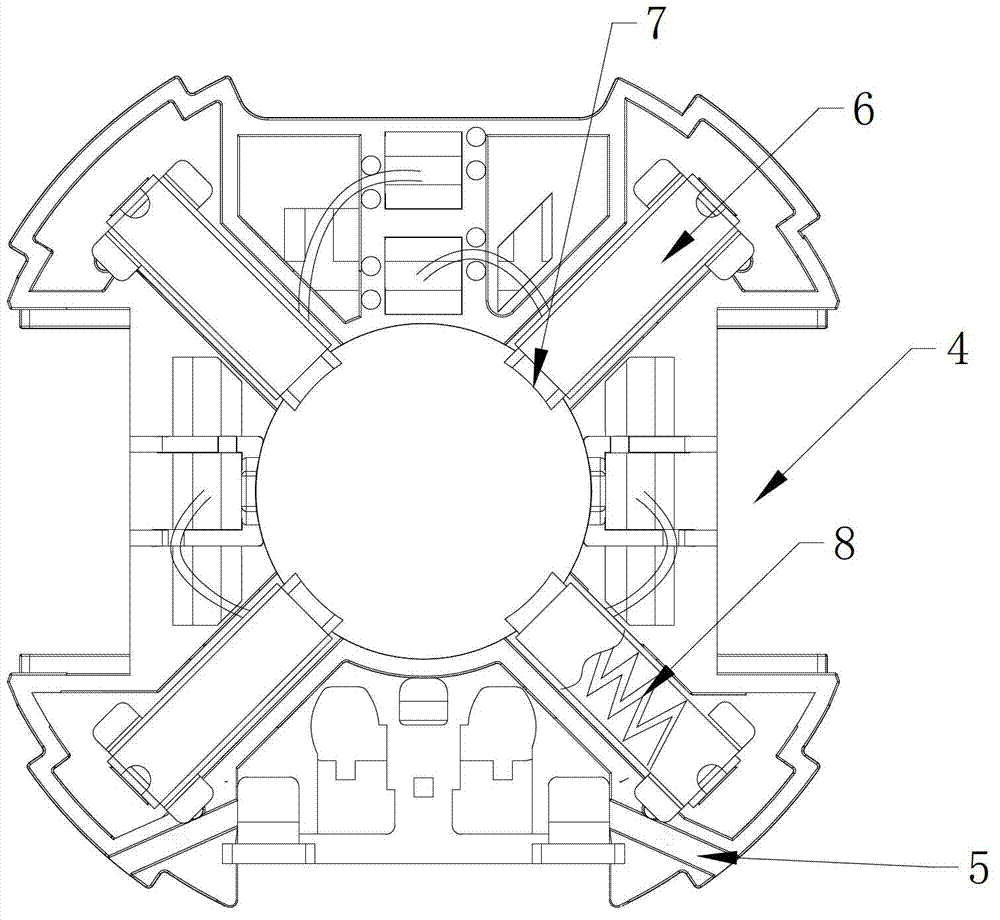

[0021] like figure 1 and figure 2 As shown, a brush holder plate for an automobile radiator fan motor includes an insulating brush holder plate body 1, and the brush holder plate also includes a conductive connecting plate 2, and the brush holder plate body 1 is evenly distributed with four A brush box mounting hole 3; the connecting plate 2 is plastic-sealed in the brush holder plate body 1, and the connecting plate 2 includes a first electrical link for one-to-one correspondence with the carbon brushes 7 installed on the brush holder plate body 1. The conductive segment 21, the second conductive segment 22, the third conductive segment 23 and the fourth conductive segment 24, the first conductive segment 21 and the second conductive segment 22 are connected end to end, and the tail end of the third conductive segment 23 is connected to the second conductive segment. The tai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com