Terminal structure

A terminal structure and terminal technology, applied in the field of electrical connection, can solve the problems of less contact surface between the plug and the hollow terminal, large deformation of the limit shrapnel, unstable insertion and extraction force, etc., so as to alleviate the phenomenon of thermal concentration and reduce the amount of deformation. , will not contact the effect of bad

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below according to accompanying drawing and embodiment:

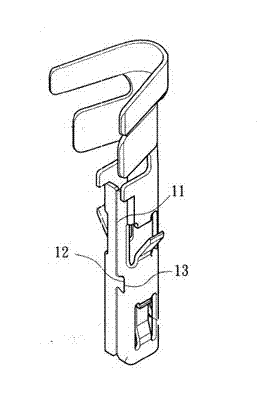

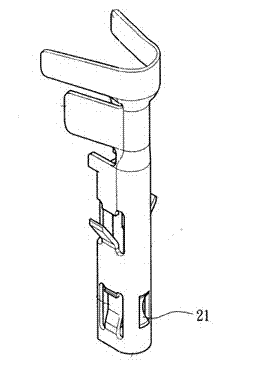

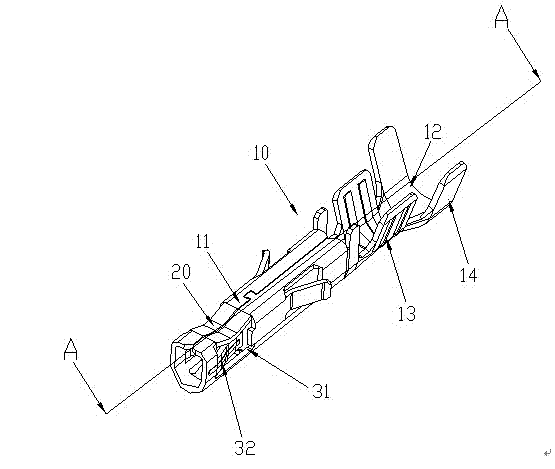

[0016] Such as image 3 As shown, the terminal structure of the present invention includes a hollow terminal head 10 with a rectangular sectional surface, which is integrally formed by stamping, and a pair of seams 11 are formed, and a connection accommodation is provided at the rear end of the hollow terminal head 10 The groove 12, the two sides of the accommodating groove 12 are symmetrically provided with a conductive pressure-bonding piece 13 and a pressure-bonding piece 14 from inside to outside. On the side wall where the butt seam 11 is formed at the front end of the hollow terminal head 10, there is provided a pressing portion 20 that is recessed into the hollow terminal head 10; two adjacent side walls where the pressing portion 20 is located On the side walls, a hollow part 31 is respectively provided, and a limit elastic piece 32 is arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com