Preparation method of composite anode of microbial fuel cell with carbon-base material modified by conductive complex

A technology of fuel cells and carbon-based materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low electricity production efficiency, achieve the effects of improving electricity production performance, saving manufacturing costs, and reducing battery internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The first step, the purification of multi-walled carbon nanotubes: put the multi-walled carbon nanotubes with a diameter of 8~15nm and a length of 30~60μm in a beaker, add a mixed acid solution (V[concentrated H 2 SO 4 ]:V[HNO 3 ]=3:1), at 30°C, 40~80Hz ultrasonic for 6 hours, forming carbon nanotube acid solution, washed with deionized water until neutral, vacuum filtered, then washed 6 times with absolute ethanol, and then continued to repeat the ultrasonic Wash 5 times (5 min / time), vacuum filter until the filtrate is transparent and colorless, and dry the purified carbon nanotubes in vacuum;

[0024] In the second step, put the purified multi-walled carbon nanotubes into 0.1~0.5mol / L sodium sulfate aqueous solution, the content of multi-walled carbon nanotubes is 5%~20%, ultrasonic 30min, so that the carbon nanotubes are dispersed in the solution ; Add 3,4-ethylenedioxythiophene monomer to it at a concentration of 0.01mol / L, and ultrasonicate for 5 hours to prepar...

Embodiment 2

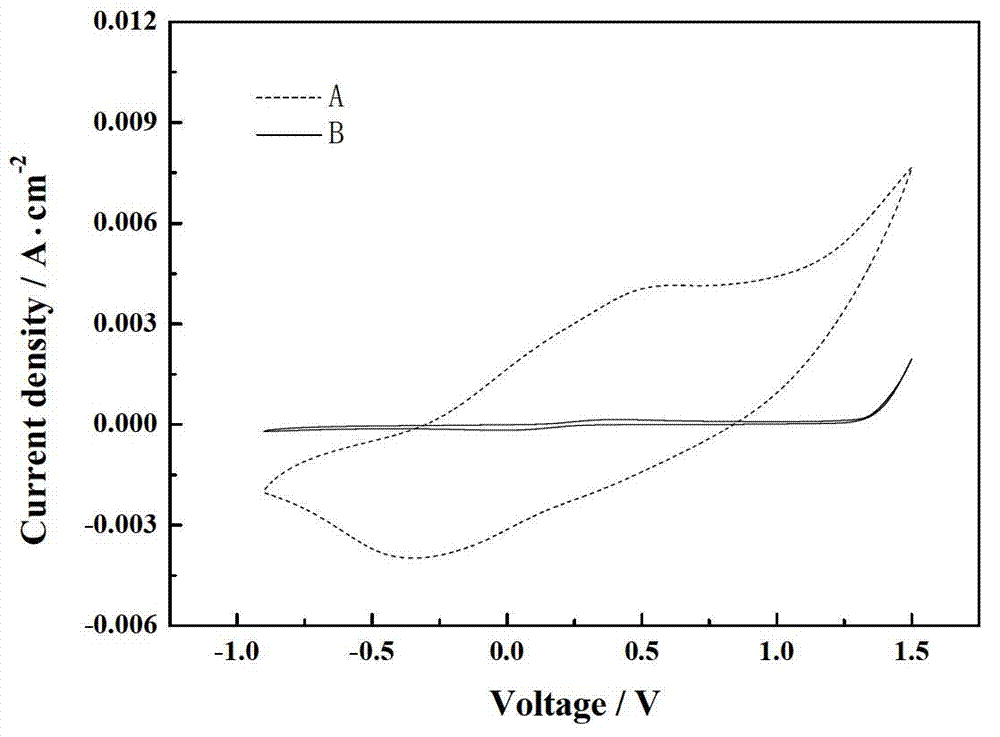

[0030] The anode compartment of the microbial fuel cell is a cylindrical plexiglass anaerobic fluidized bed reactor (see image 3 , image 3 Among them, 1 represents the liquid storage tank, 2 represents the anaerobic fluidized bed body, 3 represents the anode, 4 represents the peristaltic pump, 5 represents the air cathode, and 6 represents the resistance box), with a diameter of 40 mm and a height of 600 mm. The perforated plate liquid distributor has a porosity of 20% and a pore diameter of 2 mm. The anode chamber is filled with coconut shell activated carbon, the particle size dp is 0.45-0.9mm, and the porosity ε=0.45. The modified anodes before modification and 24 circles of polymerization are put into the anode chamber to conduct electrons, and the effective volume of the anode chamber is 1L. The content of loaded platinum is 0.35mg m -2 The carbon cloth is used as the cathode with a diameter of 20 mm, and the oxygen in the air is used as the electron acceptor. The sewa...

Embodiment 3

[0034] The first step, the purification of multi-walled carbon nanotubes: put the multi-walled carbon nanotubes with a diameter of 8~15nm and a length of 30~60μm in a beaker, add a mixed acid solution (V[concentrated H 2 SO 4 ]:V[HNO 3 ]=3:1), at 60°C, 40~80Hz ultrasonic for 8 hours, forming carbon nanotube acid solution, washed with deionized water until neutral, vacuum filtered, then washed with absolute ethanol for 5 times, and then continued to repeat the ultrasonic Wash 3 times (5 min / time), vacuum filter until the filtrate is transparent and colorless, and dry the purified carbon nanotubes in vacuum;

[0035] In the second step, put the purified multi-walled carbon nanotubes into 0.1~0.5mol / L sodium sulfate aqueous solution, the content of multi-walled carbon nanotubes is 5%~20%, and ultrasonically disperse the carbon nanotubes in the solution for 20 minutes ; Add 3,4-ethylenedioxythiophene monomer to it at a concentration of 0.02 mol / L, and ultrasonicate for 6 hours t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com