Testing and adjusting linkage system and operating process thereof

A linkage system, measurement and adjustment technology, applied in the directions of measurement, production of fluids, wellbore/well components, etc., can solve the problems such as the inability of stepless adjustment of fixed nozzles, the increase of workload and difficulty, and the restriction of oilfield productivity, etc. Test efficiency, small workload, and the effect of shortening test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

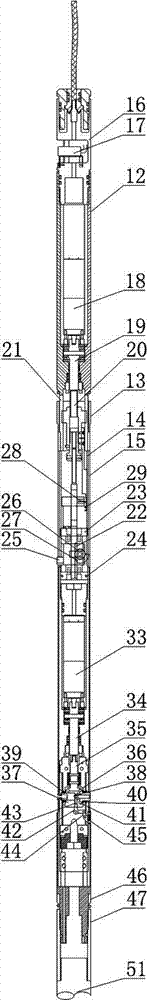

[0041] Such as figure 1 , image 3 As shown, the measurement and adjustment linkage system includes a water distributor 1 and a measurement and adjustment device 2 arranged inside the water distributor 1, such as figure 1 , figure 2 As shown, the water distributor 1 includes a main housing 3 and a guide rail sleeve 4 arranged inside the main housing 3. An upper joint 5 is installed on the upper end of the main housing 3. The upper joint 5 is provided with an axial through hole. The upper joint 5 The outer wall of the lower part is provided with threads, which are connected with the internal threads arranged on the upper part of the inner wall of the outer casing, and a sealing ring is provided between the outer wall of the upper joint 5 and the inner wall of the inner housing, and the inner wall of the upper joint 5 is stepped, and the step of the inner wall The upper magnet 6 and the upper magnet gland 7 are respectively arranged in the shaped groove, and the outer wall of...

Embodiment 2

[0062] Such as figure 1 , Figure 5 As shown, the measurement and adjustment linkage system includes a water distributor 1 and a measurement and adjustment device 2 arranged inside the water distributor 1, such as figure 1 , figure 2 As shown, the water distributor 1 includes a main housing 3 and a guide rail sleeve 4 arranged inside the main housing 3. An upper joint 5 is installed on the upper end of the main housing 3. The upper joint 5 is provided with an axial through hole. The upper joint 5 The outer wall of the lower part is provided with threads, which are connected with the internal threads arranged on the upper part of the inner wall of the outer casing, and a sealing ring is provided between the outer wall of the upper joint 5 and the inner wall of the inner housing, and the inner wall of the upper joint 5 is stepped, and the step of the inner wall The upper magnet 6 and the upper magnet gland 7 are respectively arranged in the shaped groove, and the outer wall o...

Embodiment 3

[0084] Such as figure 1 , Image 6 As shown, the measurement and adjustment linkage system includes a water distributor 1 and a measurement and adjustment device 2 arranged inside the water distributor 1, such as figure 1 , figure 2 As shown, the water distributor 1 includes a main housing 3 and a guide rail sleeve 4 arranged inside the main housing 3. An upper joint 5 is installed on the upper end of the main housing 3. The upper joint 5 is provided with an axial through hole. The upper joint 5 The outer wall of the lower part is provided with threads, which are connected with the internal threads arranged on the upper part of the inner wall of the outer casing, and a sealing ring is provided between the outer wall of the upper joint 5 and the inner wall of the inner housing, and the inner wall of the upper joint 5 is stepped, and the step of the inner wall The upper magnet 6 and the upper magnet gland 7 are respectively arranged in the shaped groove, and the outer wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com