Wash apron anti-settling anti-cracking construction method and structure

A construction method and anti-cracking technology, which can be applied to underwater structures, water conservancy projects, infrastructure projects, etc., can solve problems such as excessive water content in the soil of the scattered water base, unbearable stress of the scattered water, and difficulty in controlling the flatness, etc., to achieve increased Water-dispersing tensile ability, avoiding overall surface tension shrinkage, and improving strength

Inactive Publication Date: 2012-11-14

庆阳华晨建筑安装工程有限公司

View PDF4 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The conventional method is to cast the mold at one time according to the design thickness, and it is difficult to control its flatness during construction. Moreover, some projects are constr

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

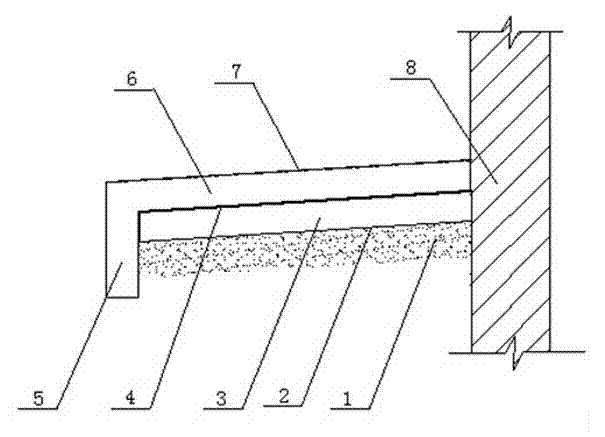

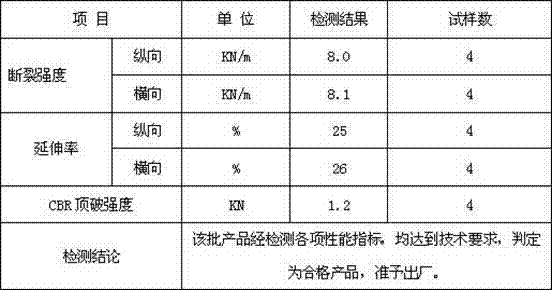

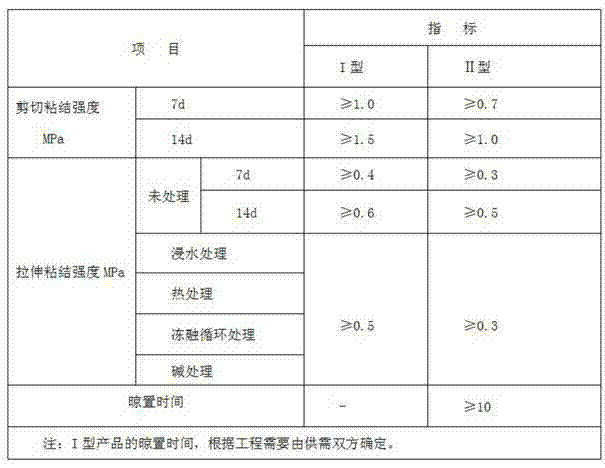

The invention discloses a wash apron anti-settling anti-cracking construction method and a structure. The construction method comprises the following steps: firstly adding a geotextile layer on the upper surface of a 3-7 lime earth layer, then pouring a first layer of concrete wash apron; arranging an olecranon-shaped groove on the outer edge of the first layer of concrete wash apron, arranging an adhesion agent layer on the surface of the first layer of concrete wash apron, then pouring a second layer of concrete wash apron, and an olecranon-shaped concrete cast-in-place belt; and at last arranging an alkali-resisting fiberglass gridding cloth layer under the surface of the second layer of concrete wash apron. The wash apron anti-settling anti-cracking construction method and structure can effectively prevent outdoor wash apron anti-settling anti-cracking construction method and structure from seeping in, cannot have frost crack during 8-10 years using period, is durable, and the service life can be 2-3 times of that of common wash apron. Labor power, material resources and financial resources input at later-stage maintenance are saved, economic benefit and social benefit are obvious, and popularization value is wide.

Description

technical field [0001] The invention relates to a construction method and a structure of loose water in collapsible loess areas, in particular to a construction method and structure of outdoor water scattering and anti-sinking and anti-cracking of a house construction project where the outdoor ground is not hardened. Background technique [0002] In collapsible loess areas, such as Qingyang City located in the Loess Plateau of Longdong, the loess is widely distributed and thick, and it is the main carrier of various buildings, roads and other structures. However, under the influence of negative temperature in the cold winter season, a considerable number of building water and ground and road surfaces swelled significantly. After repeated freeze-thaw cycles, the structure of the soil changed. The porosity of the soil samples increased after the freeze-thaw cycle compared with that before the freeze-thaw cycle. With the increase of the number of freeze-thaw cycles, the collaps...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E02D29/045E02D31/00E02D31/14

Inventor 左凤瑄左家军张振安张建仓敬瑞亮曹和平

Owner 庆阳华晨建筑安装工程有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com