Damped water reducing agent and preparation method for concrete

A concrete water-reducing agent and mud-blocking technology, applied in the field of water-reducing agents, can solve the problems of large amount of water-reducing agent, low water-reducing rate, unstable quality, etc., and achieve the effect of inhibiting expansion and dispersion and achieving good water-reducing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

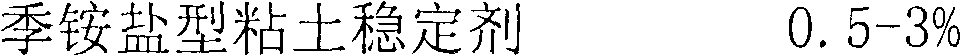

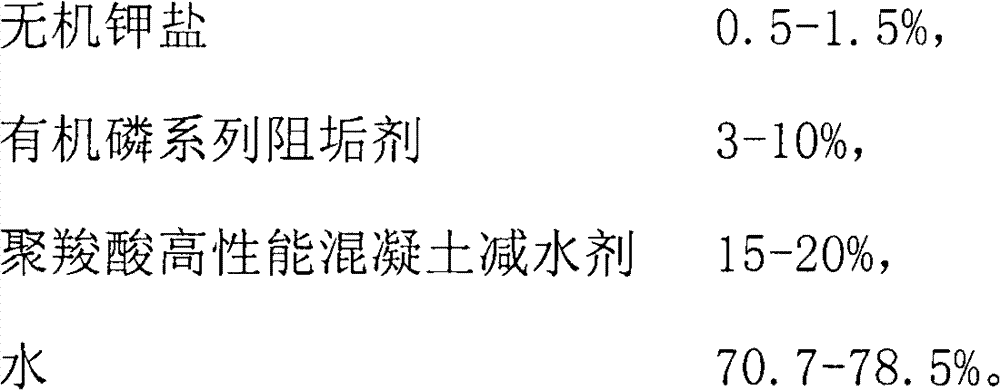

[0028] Preparation of quaternary ammonium salt-type clay stabilizer: In a constant temperature water bath at 30°C, add epichlorohydrin to the reaction vessel, then slowly add aqueous dimethylamine solution dropwise, stir at a low speed, and then add dropwise the crosslinking agent ethylenediamine, Immediately after adding the initiator sodium sulfite and potassium persulfate, the temperature was raised to 45°C and the reaction was stopped for 6 hours to obtain a quaternary ammonium salt type clay stabilizer.

[0029] Preparation of polycarboxylate high-performance concrete water reducer: add 5% maleic anhydride, 20% polyethylene glycol monomethyl ether and 30% water to the reaction vessel, stir and heat to 80°C , and then dropwise added 3.5% of methacrylic acid, 5% of hydroxypropyl methacrylate, 1.5% of sodium methallylsulfonate and 35% of water to prepare an aqueous monomer solution. The dropping time is 3 hours, the dropping temperature is 70-80° C., the polymerization react...

Embodiment 2

[0032] Preparation of quaternary ammonium salt-type clay stabilizer: In a constant temperature water bath at 30°C, add epichlorohydrin to the reaction vessel, then slowly add aqueous dimethylamine solution dropwise, stir at a low speed, and then add dropwise the crosslinking agent ethylenediamine, Immediately after adding the initiator sodium sulfite and potassium persulfate, the temperature was raised to 45°C and the reaction was stopped for 6 hours to obtain a quaternary ammonium salt type clay stabilizer.

[0033] Preparation of polycarboxylate high-performance concrete water reducer: add 5% maleic anhydride, 20% polyethylene glycol monomethyl ether and 30% water to the reaction vessel, stir and heat to 80°C , and then dropwise added 3.5% of methacrylic acid, 5% of hydroxypropyl methacrylate, 1.5% of sodium methallylsulfonate and 35% of water to prepare an aqueous monomer solution. The dropping time is 3 hours, the dropping temperature is 70-80° C., the polymerization react...

Embodiment 3

[0036] Preparation of quaternary ammonium salt-type clay stabilizer: In a constant temperature water bath at 30°C, add epichlorohydrin to the reaction vessel, then slowly add aqueous dimethylamine solution dropwise, stir at a low speed, and then add dropwise the crosslinking agent ethylenediamine, Immediately after adding the initiator sodium sulfite and potassium persulfate, the temperature was raised to 45°C and the reaction was stopped for 6 hours to obtain a quaternary ammonium salt type clay stabilizer.

[0037] Preparation of polycarboxylate high-performance concrete water reducer: add 5% maleic anhydride, 20% polyethylene glycol monomethyl ether and 30% water to the reaction vessel, stir and heat to 80°C , and then dropwise added 3.5% of methacrylic acid, 5% of hydroxypropyl methacrylate, 1.5% of sodium methallylsulfonate and 35% of water to prepare an aqueous monomer solution. The dropping time is 3 hours, the dropping temperature is 70-80° C., the polymerization react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com