Protective gas for welding stainless steel

A technology of shielding gas and stainless steel, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problem of small penetration depth, increase penetration depth, widen the cross-sectional area of weld seam, and improve the wetting degree of welding beads Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0018] The shielding gas for stainless steel welding of the present invention is formed by mixing argon and hydrogen. The weight percentage of argon is 95%, and the weight percentage of hydrogen is 5%. In view of the particularity of argon-hydrogen mixed gas, hydrogen is a highly flammable gas. When the mixed gas of hydrogen and oxygen or air comes into contact with flame or other fire sources in a limited area, it will explode. Therefore, it is necessary to select the welding environment. Avoid use in closed environments.

[0019] The following is the situation of the test panel and the finished welding product:

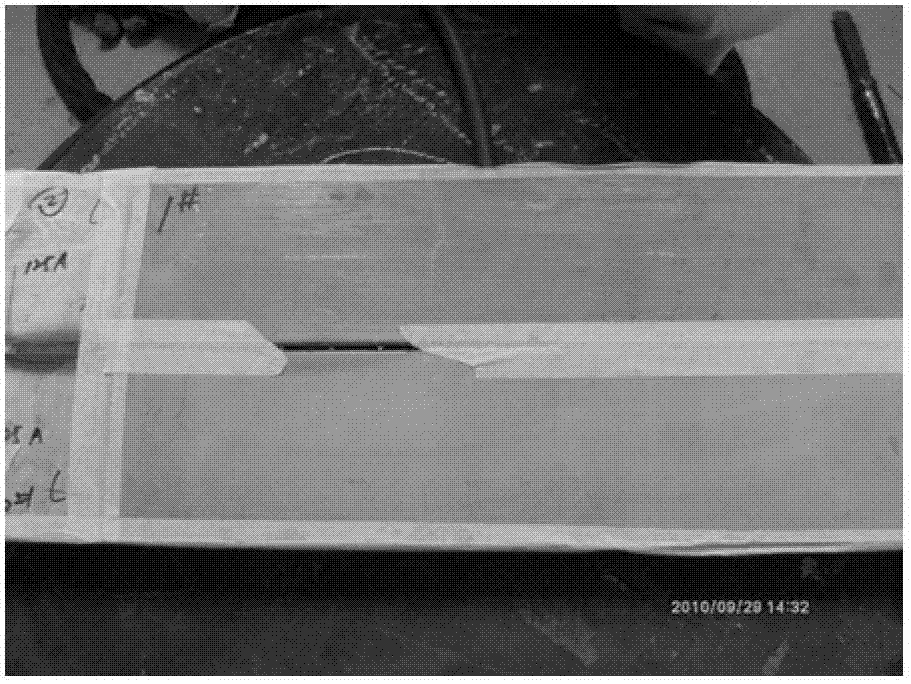

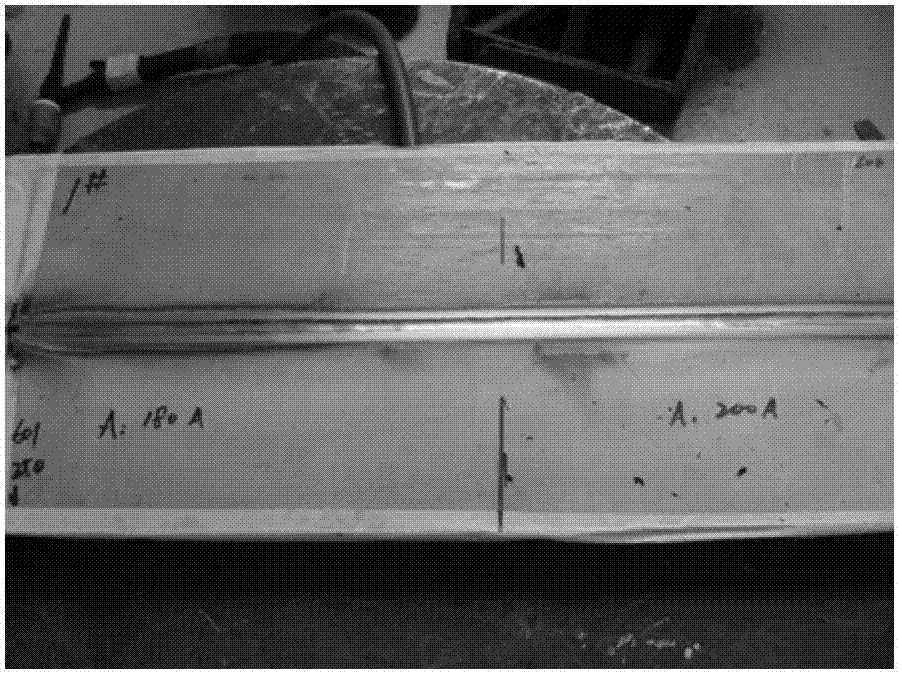

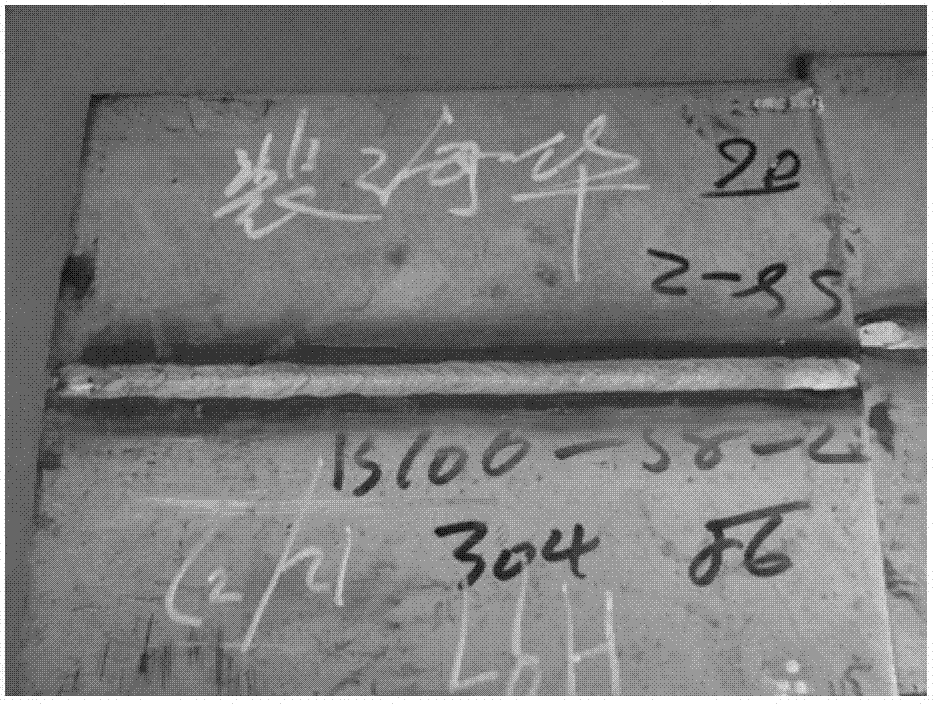

[0020] 1. Use 95% Ar and 5% H welding shielding gas to carry out butt welds of stainless steel plates with a thickness of 6 mm. The groove form is V-shaped, the chamfer is 70, the blunt edge is 2mm, and the gap is 0-1mm. see fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com