Small-section square girder and welding process thereof

A welding process and small cross-section technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of low welding quality, achieve the effects of improving torsion resistance, long longitudinal length, ensuring stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

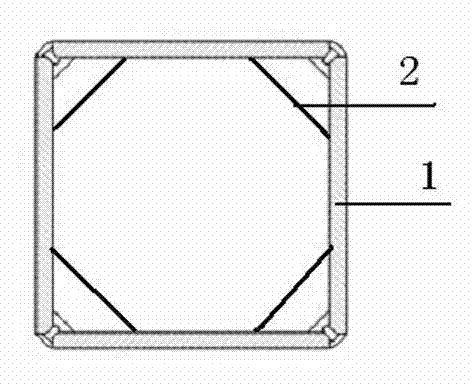

[0027] Such as figure 1 A small cross-section square girder shown in the figure consists of four pairs of beam plates with a width of 200mm and a length of 9m to form a box-shaped inner cavity, and a rib plate 2 is arranged in the inner cavity, and flanges are welded at both ends of the beam plate 1. The inner and outer fillet welds are used between beams and slabs and between beams and flanges.

[0028] When soldering, the following steps are involved:

[0029] 1. Before welding, clean up the oil, dirt, scale, etc. in the 25mm area on both sides of the weld;

[0030] 2. Install welding arc starting plate and arc closing plate;

[0031] 3. Use the automatic welding trolley to carry out the bottom welding of the inner cavity boat welding, starting from the arc striking plate to the arc closing plate, the welding seam height is 5~6mm, and welding is performed in diagonal order during welding; the diameter of the welding wire is φ1 .2; welding current 120~150A; arc voltage 22~...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com