Waste gas oxidation treatment system

An oxidation treatment and waste gas technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of hydrogen peroxide being unable to be self-sufficient, economic efficiency is reduced, and oxidizing properties are limited, so as to achieve good oxidation treatment effect and reduce equipment. The effect of reducing the input and processing costs of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described below with reference to the drawings and embodiments.

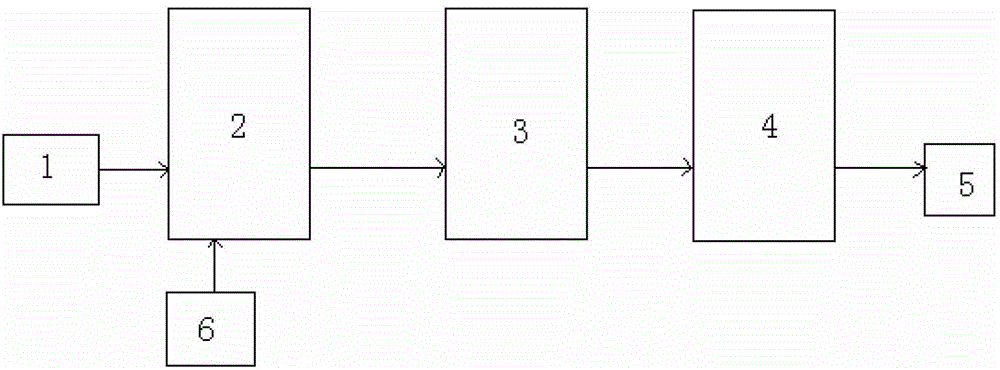

[0011] Such as figure 1 As shown, an exhaust gas oxidation treatment system of the present invention includes an exhaust gas collection area 1, an oxidation spray tower 2, a catalytic oxidation tower 3, an acid-base neutralization tower 4, an exhaust fan 5, and a chimney. The oxidation spray tower 2 consists of There are defogging layer, spray layer, filler layer and aeration layer from top to bottom. The aeration layer is composed of several aeration discs. The ozone outlet of the ozone generator 6 communicates with the aeration layer in the oxidation spray tower 2. The exhaust gas outlet of the exhaust gas collection zone 1 is connected to the inlet of the oxidation spray tower 2 through the exhaust pipe, and the outlet of the oxidation spray tower 2 is connected to the inlet of the catalytic oxidation tower 3 through the exhaust pipe. The outlet of the catalytic oxidation tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com