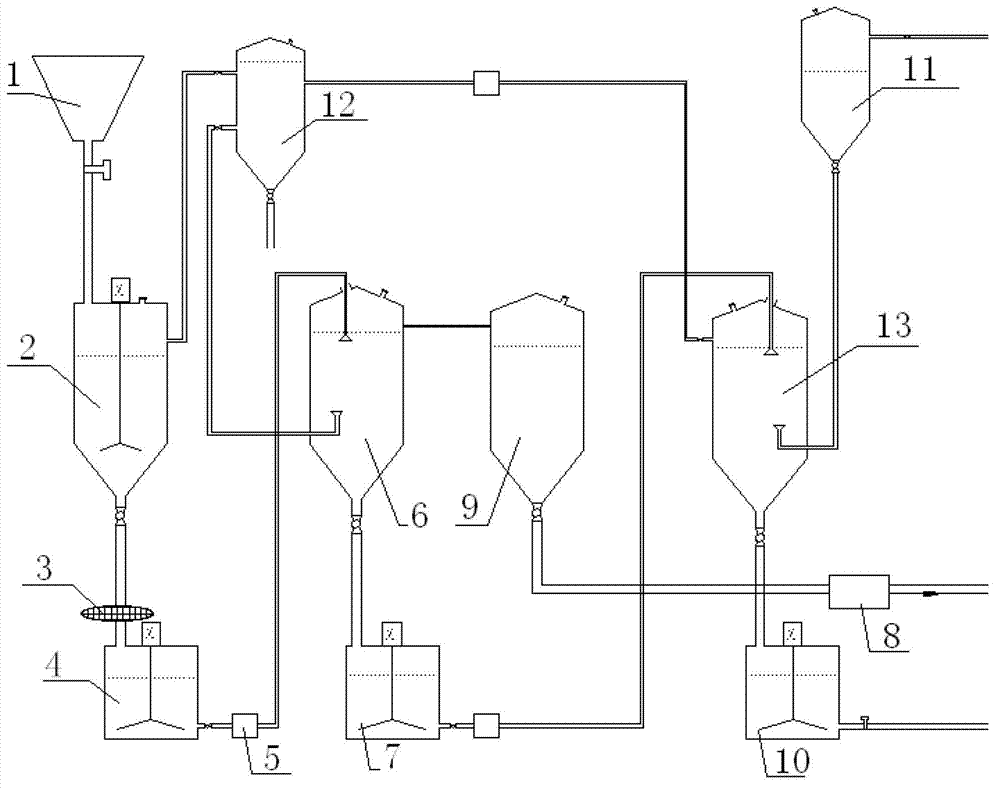

Device and method for extracting effective components from natural plant by high-pressure spraying reverse-flow process

A natural plant, high-pressure spray technology, applied in solid solvent extraction and other directions, can solve the problems of high-pressure spray method for extracting active ingredients from natural plants, inability to achieve continuous production, and high heat sensitivity of active ingredients. The effect of reducing the loss of heat-sensitive active ingredients and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Step 1. Removal of impurities: Taking salvia miltiorrhiza as an example, firstly, 300kg of salvia miltiorrhiza raw materials that have passed the inspection are manually selected to remove impurities;

[0022] Step 2, crushing: putting the natural plants to be extracted after removing impurities into a crushing machine with a built-in 120-mesh screen for crushing;

[0023] Step 3, prepare the material suspension and pass through the screen: put the pulverized natural plant material to be extracted from the raw material box 1 into the No. 1 mixing tank 2 with a built-in agitator, and then pour it into the No. Add soaking solution to the natural plant raw material, the soaking solution is ethanol solution with a volume concentration of 90%, stir and soak for 1.5h, and the stirring rate is 80r / min; the obtained material suspension flows into the No. 2 stirring tank through a 100 mesh screen 3 Stirring in 4 for subsequent use; the volume-to-weight ratio between the added so...

Embodiment 2

[0027] Embodiment two: basically the same as embodiment one, the difference is that the extracted natural plant is licorice, and the extraction solvent is water.

Embodiment 3

[0028] Embodiment three: basically the same as embodiment one, the difference is that the natural plant extracted is rhubarb, and the extraction solvent is 60% ethanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com