PLGA(polylactic-co-glycolic acid)/hydroxyapatite/calcium carbonate compound microspheres and preparation method thereof

A technology of hydroxyapatite and composite microspheres is applied in the field of preparation of biomedical materials, which can solve the problems of unfavorable degradable material application, slow degradation rate of hydroxyapatite, etc., so as to improve bone repair ability, avoid residues, and improve bone quality. The effect of osteoconductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

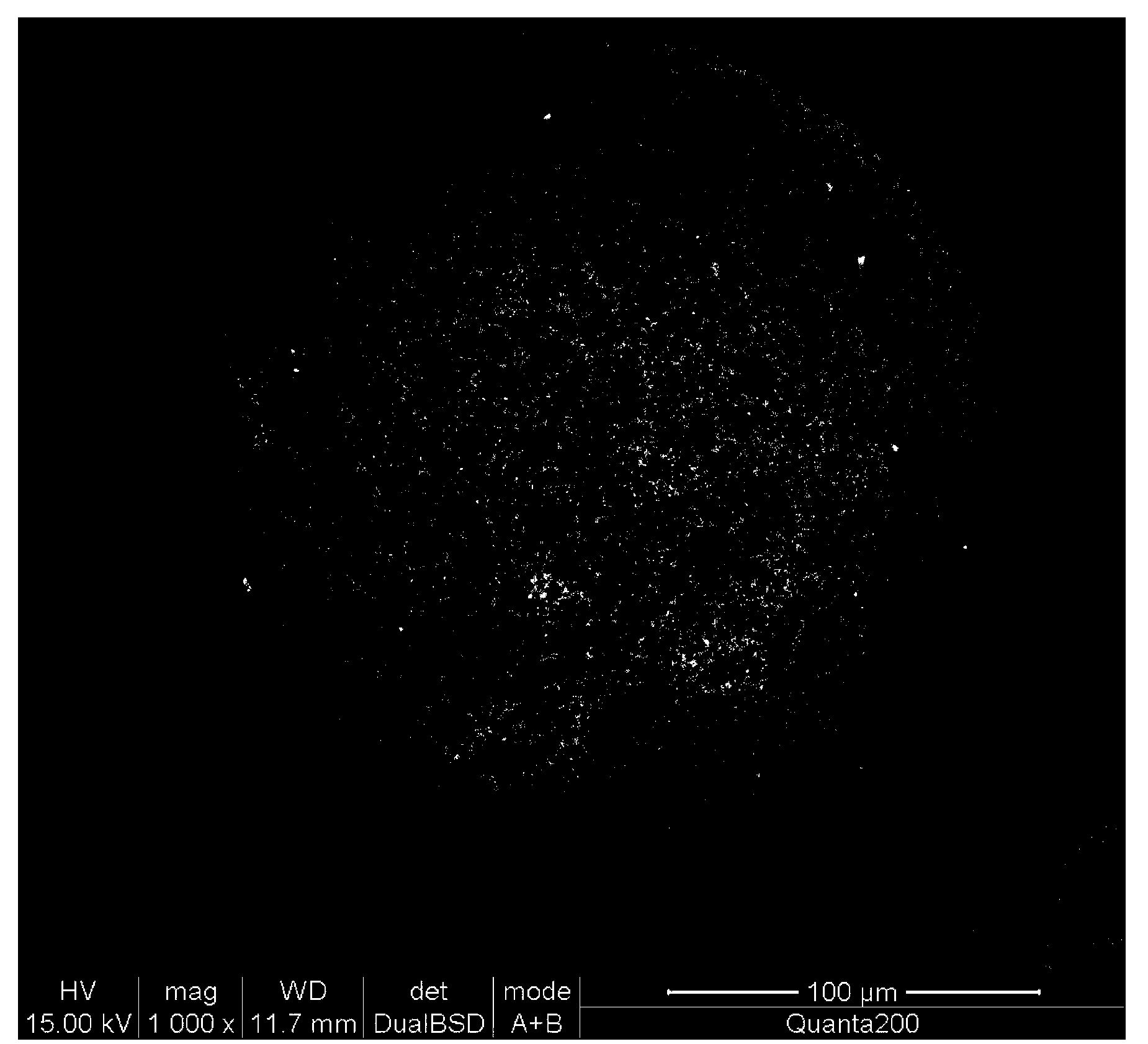

Embodiment 1

[0035] Weigh 1 g of PLGA and 5 mg of dexamethasone and dissolve them in 20 mL of dichloromethane to obtain 20 mL of PLGA organic solution. Weigh 0.5g of hydroxyapatite and 0.2g of calcium carbonate and add to 20mL PLGA organic solution, and stir at 300rpm and 300w ultrasonic power for 10min to obtain a mixed solution of PLGA / hydroxyapatite / calcium carbonate. Weigh 4g of PVA and add it into 500mL of deionized water, heat to 90°C under stirring to dissolve the PVA, and obtain a PVA aqueous solution after cooling. Weigh 0.6g of gluconolactone and dissolve in PVA aqueous solution to obtain acidic PVA aqueous solution. The PLGA / hydroxyapatite / calcium carbonate mixed solution was added dropwise to the acidic PVA aqueous solution under the stirring condition of 350rpm to obtain an oil-in-water single emulsion. The single emulsion was continuously stirred in a fume hood at 350 rpm for 24 hours to volatilize the dichloromethane in the single emulsion and solidify the oil droplets into...

Embodiment 2

[0037] The difference between this example and Example 1 is that no gluconolactone is added to the PVA aqueous solution. Compared with the microspheres in Example 1, the surface pores of the microspheres in this example are mostly closed structures.

Embodiment 3

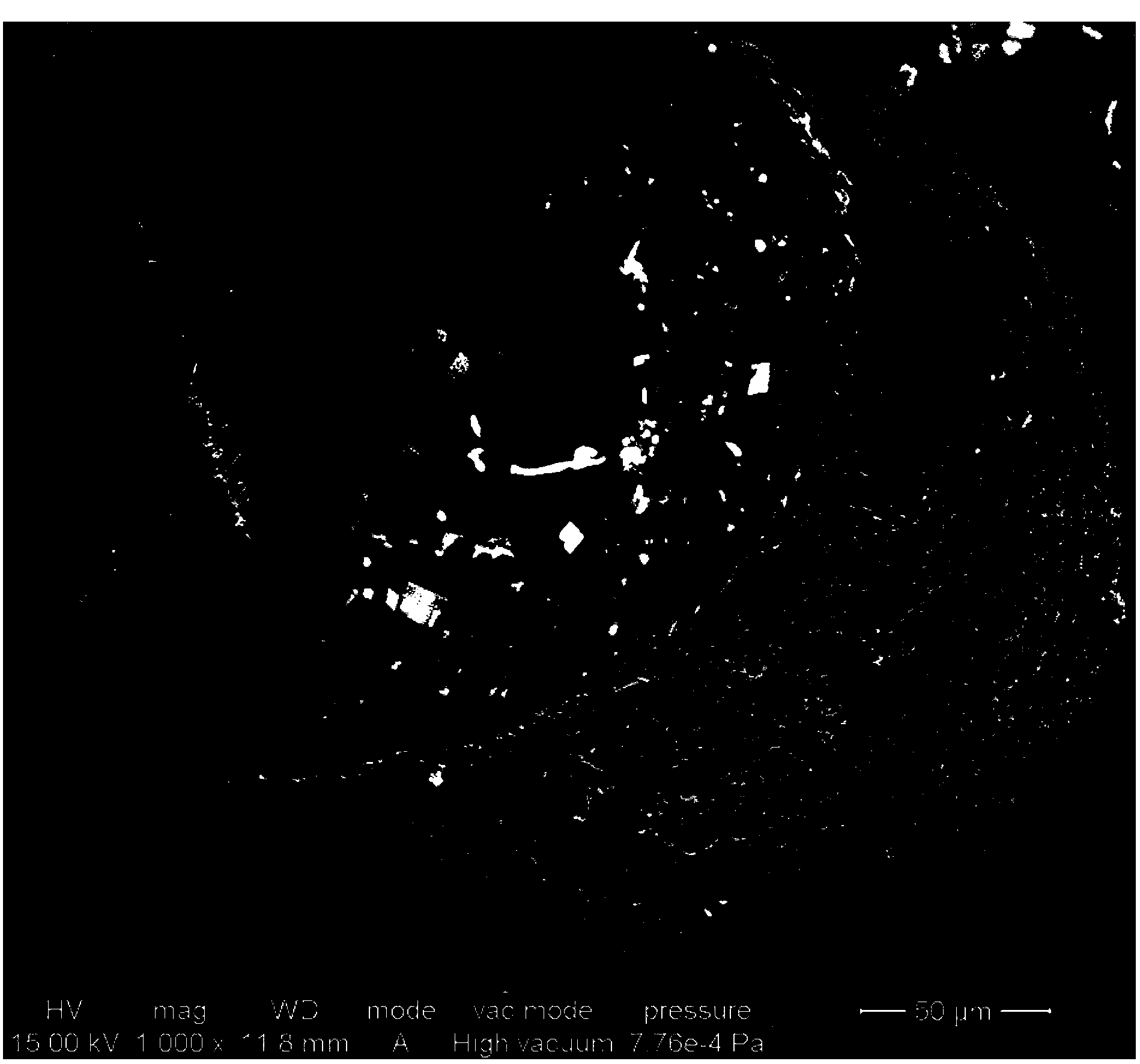

[0039] Weigh 1 g of PLGA and dissolve it in 20 mL of dichloromethane to obtain 20 mL of PLGA organic solution. Weigh 0.25g of hydroxyapatite and 0.1g of calcium carbonate into the PLGA organic solution, stir at 300rpm and 300w ultrasonic power for 10min to obtain a mixed solution of PLGA / hydroxyapatite / calcium carbonate. Weigh 1 g of PVA and add it to 500 mL of deionized water, heat to 90° C. under stirring to dissolve the PVA, and obtain a PVA aqueous solution after cooling. Weigh 0.5 g of gluconolactone and dissolve in PVA aqueous solution to obtain acidic PVA aqueous solution. The PLGA / hydroxyapatite / calcium carbonate mixture was added dropwise to the acidic PVA aqueous solution under the stirring condition of 400rpm to obtain an oil-in-water single emulsion. The emulsion was continuously stirred for 20 hours in the fume hood to volatilize the dichloromethane in the dairy industry, and the oil droplets solidified into balls. The obtained microspheres were collected, washe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com