Method for processing traditional Chinese medicinal ultramicro wall-broken capsule slices

A technology of ultra-fine wall breaking and processing methods, which can be applied in the fields of capsule delivery, pharmaceutical formulations, and resistance to vector-borne diseases. It can solve the problems of drug absorption and taste improvement, and achieve uniform and stable drug release and uniform particle size distribution. , the effect of high strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

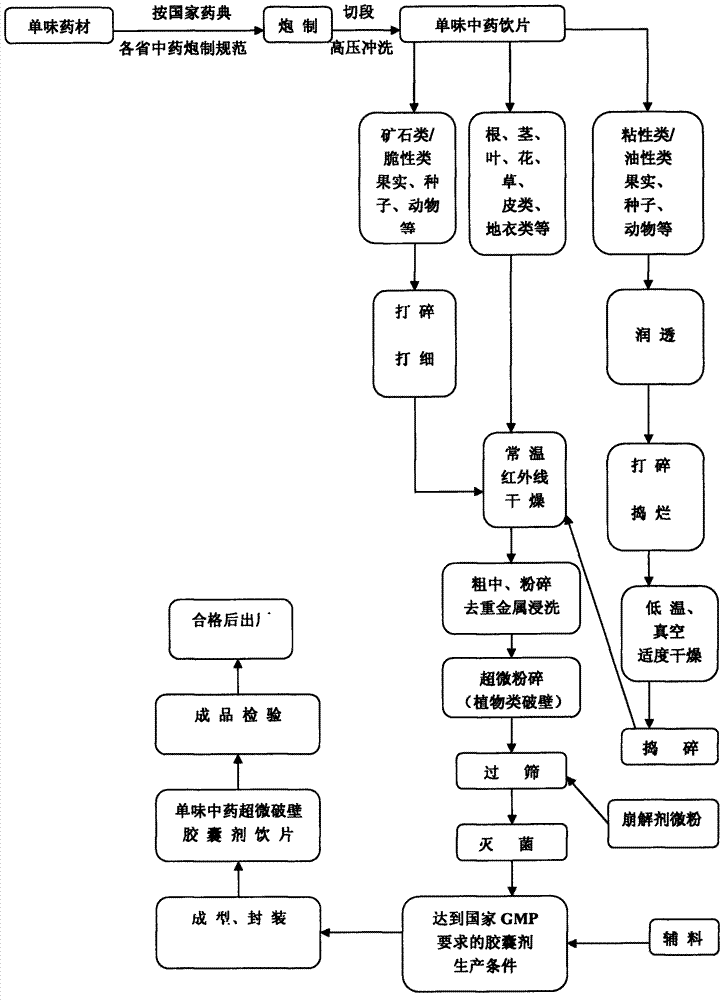

[0035] As shown in Figure 1, the processing method of the Chinese medicine ultramicro-wall-broken capsule decoction piece of the present invention mainly comprises after the standard processing and drying of the single-flavor Chinese medicinal material, and is processed into ultra-fine and broken-wall powder through ultrafine pulverization, and is achieved through quality control. After standardization, it is combined with a certain proportion of micro-powder of pharmaceutical excipients, then sterilized, and finally made into capsules and decoction pieces. The specific processing method is:

[0036] 1) Standardize the processing of single Chinese medicinal materials. Among them, the plant and animal medicinal materials are washed and cut into sections, soaked in water for half an hour, and then rinsed repeatedly for more than three times with flowing drinking water under high pressure, and the water pressure ranges from 1 to 10Mpa. Remove pesticide residues from Chinese medi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com