Micro-capsule suspension-suspending agent containing atrazine

A microcapsule suspension and microcapsule suspension technology, which is applied in the field of pesticides, can solve the problems of herbicide damage to crops, residual pollution of groundwater, poor weeding effect, etc., and achieve the effects of reducing hazards, reducing control costs, and excellent control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

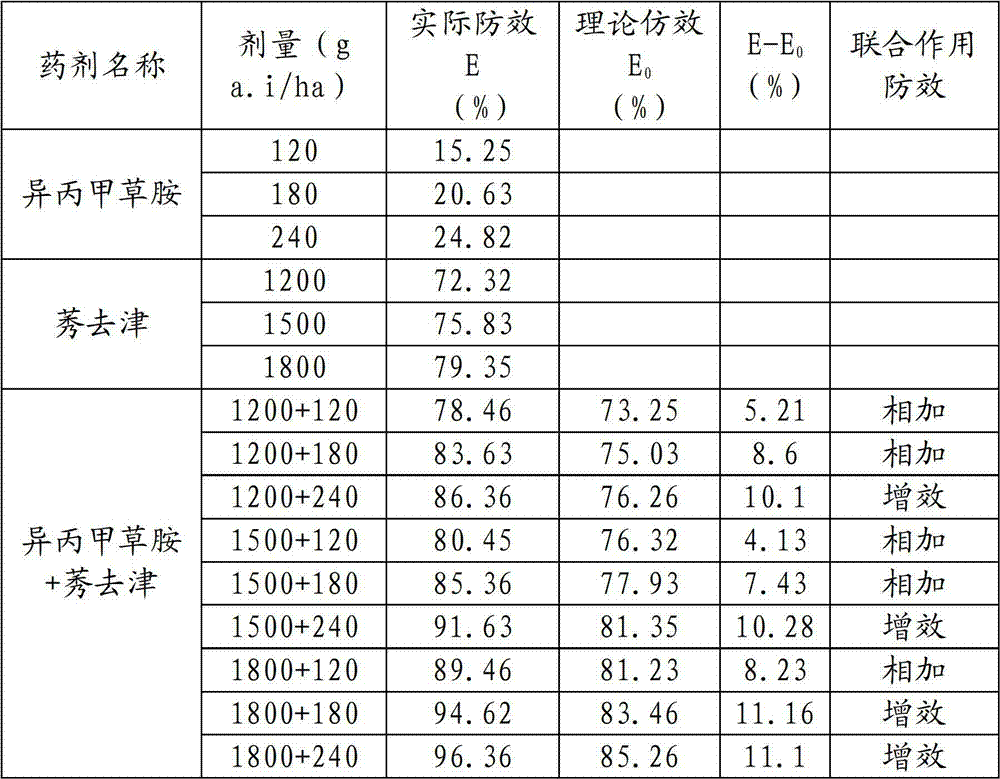

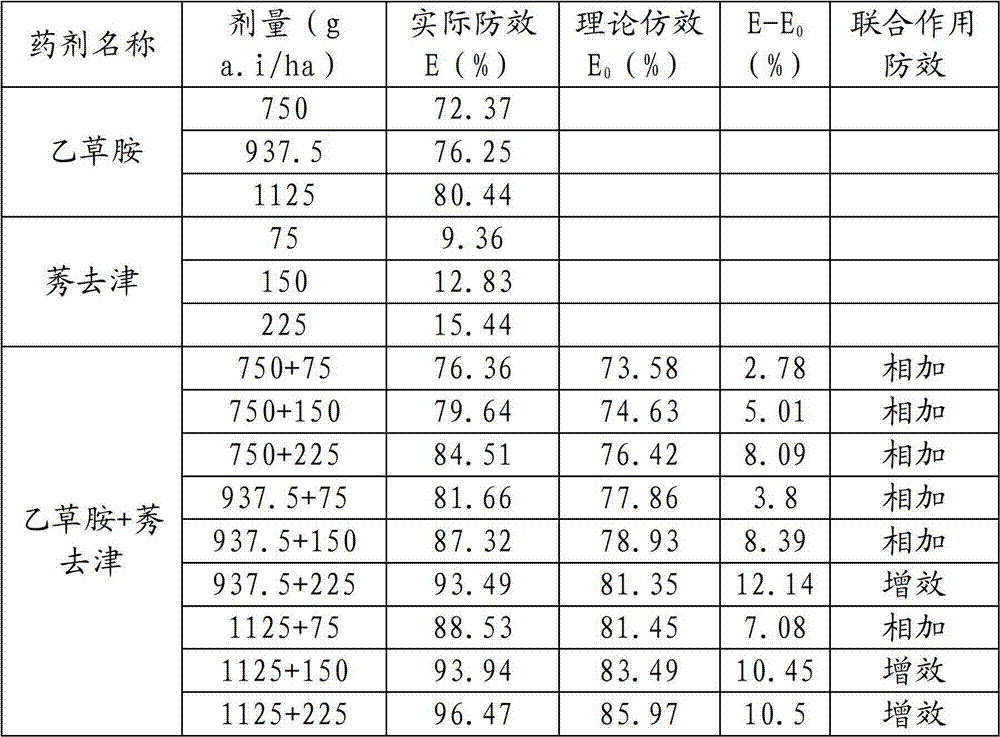

Examples

Embodiment 1

[0032] Example 1: 0.2% alachlor·atrazine microcapsule suspension-suspension agent (1:1)

[0033] Formula: alachlor 0.1kg, atrazine 0.1kg, ethylenediamine 0.1kg, alkylphenol formaldehyde resin polyoxyethylene ether sulfate 1kg, polyisocyanate 0.1kg, water to make up to 100kg.

[0034] Preparation process: In a reaction vessel with heat preservation and stirring, stir the active component II, additives, solvents and capsule wall materials evenly at high speed, then add the initiator, change to ordinary stirring, and gradually raise the temperature to 60°C, then 60°C Stir normally for 6 hours under the condition of heat preservation at ℃ to obtain a microcapsule suspension containing active component II, then add atrazine crushed to pass through a 1000 mesh sieve, and stir normally for 1 hour to obtain an atrazine-containing Microcapsule suspension-suspension agent; the process parameters are: the speed of high-speed stirring is controlled at 1000-1500 rpm, and the speed of ordin...

Embodiment 2

[0036] Example 2: 6% metolachlor-atrazine microcapsule suspension-suspension agent (1:5)

[0037] Formula: metolachlor 1kg, atrazine 5kg, triethylamine 0.4kg, ethylenediamine 0.2kg, polysorbate-80 1kg, naphthalenesulfonate formaldehyde condensate 3.5kg, gum arabic 2.5kg, water to make up to 100kg.

Embodiment 3

[0038] Example 3: 2.6% acetochlor · atrazine microcapsule suspension-suspension agent (3:10)

[0039] Formula: acetochlor 0.6kg, atrazine 2kg, ethylenediamine 0.2kg, naphthalenesulfonate formaldehyde condensate 6kg, gelatin 6kg, water to make up to 100kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com