Proportional valve, assembling method of proportional valve

A technology of proportional valves and check valves, applied in the field of proportional valves, can solve problems such as proportional valve failures, achieve the effects of short hydraulic distance, simple and reliable assembly, and minimize the risk of assembly errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

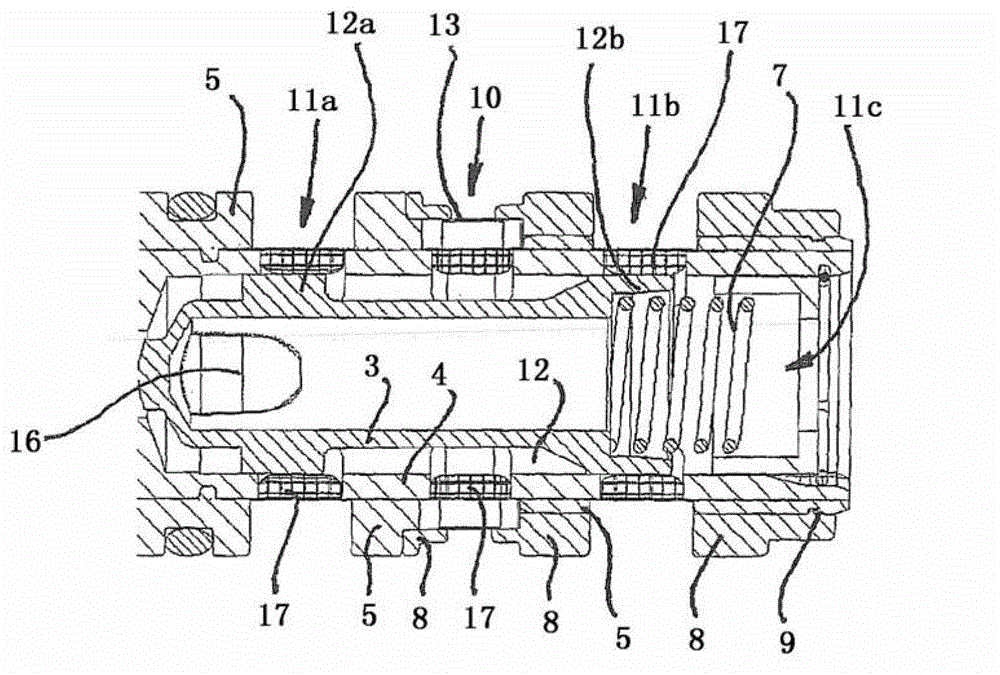

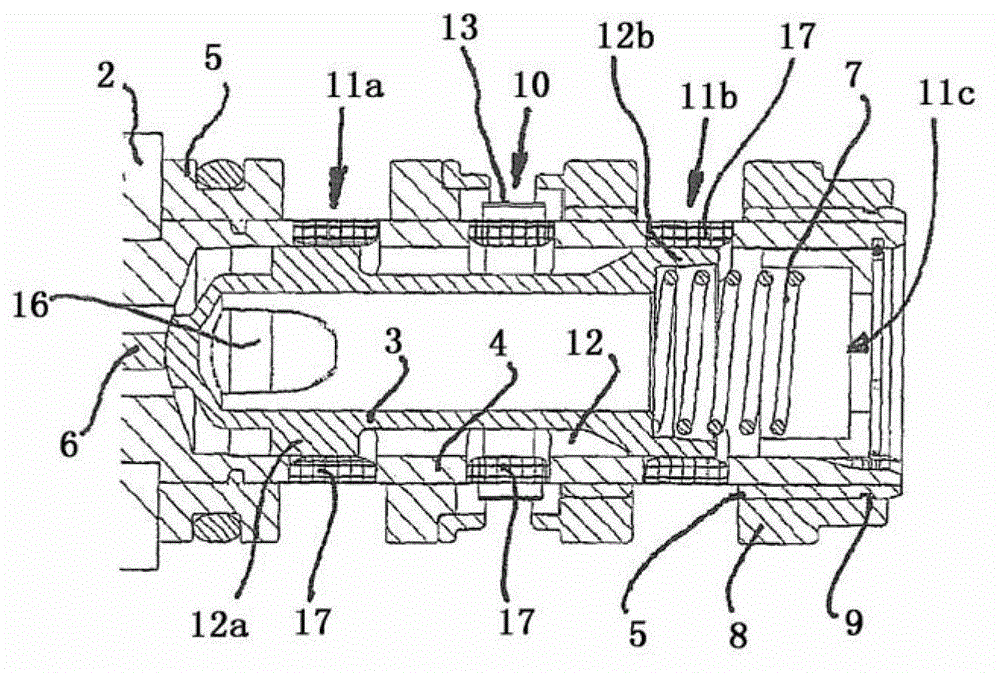

[0017] The proportional valve 1 according to the present invention is provided with a camshaft adjuster for an internal combustion engine. Here, the function of the camshaft driven by the camshaft adjuster in the internal combustion engine is that the camshaft overcomes the force of the valve spring installed on each gas exchange valve, opens the exchange for exhausting the burned gas and sucking fresh gas. Gas valve. The rigid valve timing for the gas exchange valve is for the maximum achievable medium pressure or maximum torque, its position in the usable speed range and the power that can be achieved at the rated speed. A compromise in terms of design. The camshaft adjuster can realize the optimal adaptation of the valve timing of the gas exchange valve corresponding to the respective operating state.

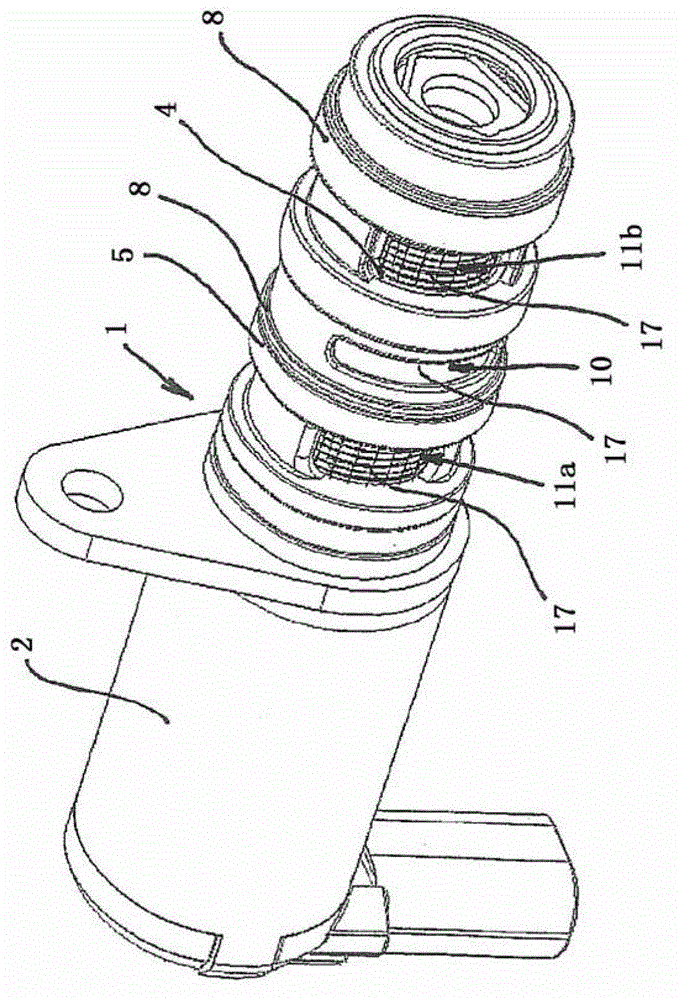

[0018] Proportional valve 1 is based on figure 1 There is an electromagnetic control part 2, the control piston 6 and the valve piston 3 ( figure 2 , 3 , 4) Co-act in propor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com