2-port isolator

An isolator and dual-port technology, applied in waveguide devices, electrical components, circuits, etc., can solve problems such as reducing connection reliability, and achieve the effect of simple assembly and high-precision assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

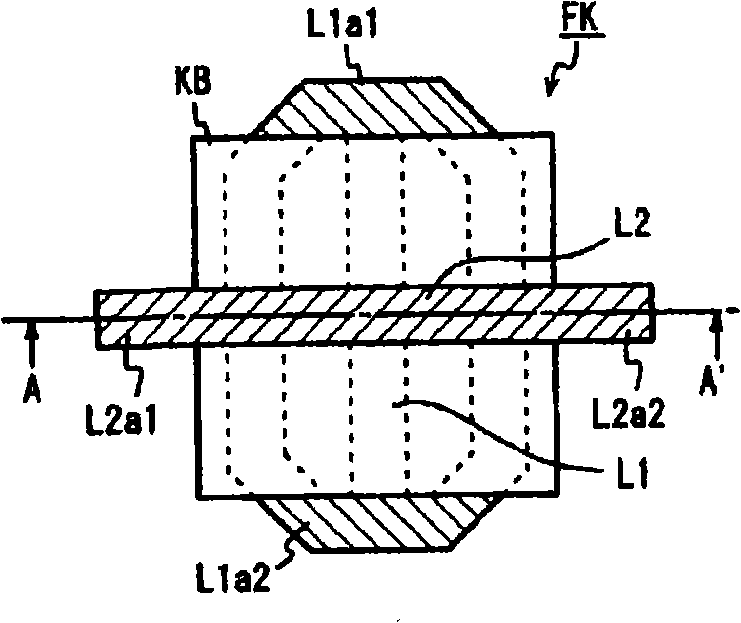

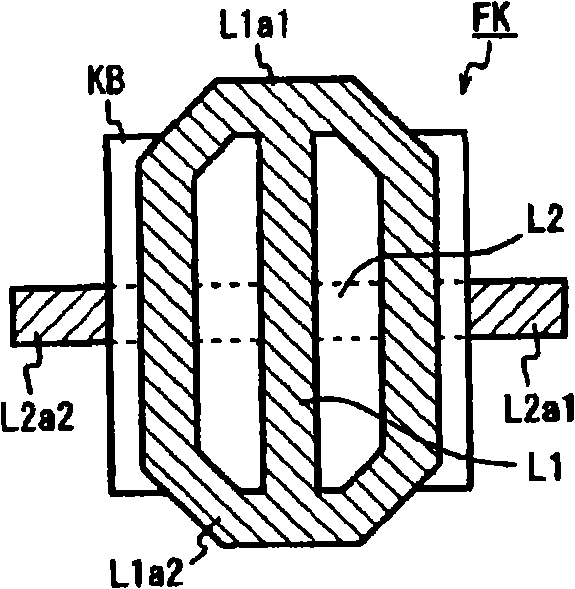

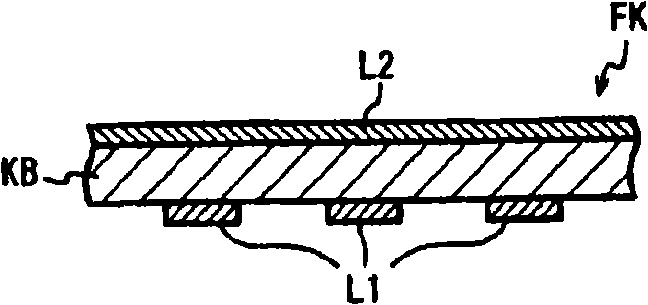

[0040] Figure 4 and Figure 5 The shown two-port isolator has: a square plate-shaped central conductor assembly 3 (having a square-shaped ferrite plate 5, and first and second ferrite plates adjacent to the ferrite plate 5 and configured to intersect in an electrically insulated state. central conductor L1, L2); a multilayer substrate 10 formed with first and second matching capacitors; accommodating the central conductor assembly 3 and the multilayer substrate 10, integrally formed with 6 external parts connected to the mother board (mother board) Resin lower case for terminals IN (P1), OUT (P2), and GND (only referred to as "resin lower case integrated with external terminals") 25; permanent magnet 30 for applying a DC magnetic field to the ferrite plate 5; And the upper case 22 made of magnetic metal that accommodates the permanent magnet 30 and forms a magnetic circuit. The first and second central conductors L1 and L2 are constituted by strip-shaped conductor patterns ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com