Motor steering return structure

A technology of positioning slots for automobiles, applied to vehicle components, optical signals, signaling devices, etc., can solve problems affecting the return function of the car, failure to return, and reliability cannot be guaranteed, etc., to achieve simple and reliable assembly methods and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

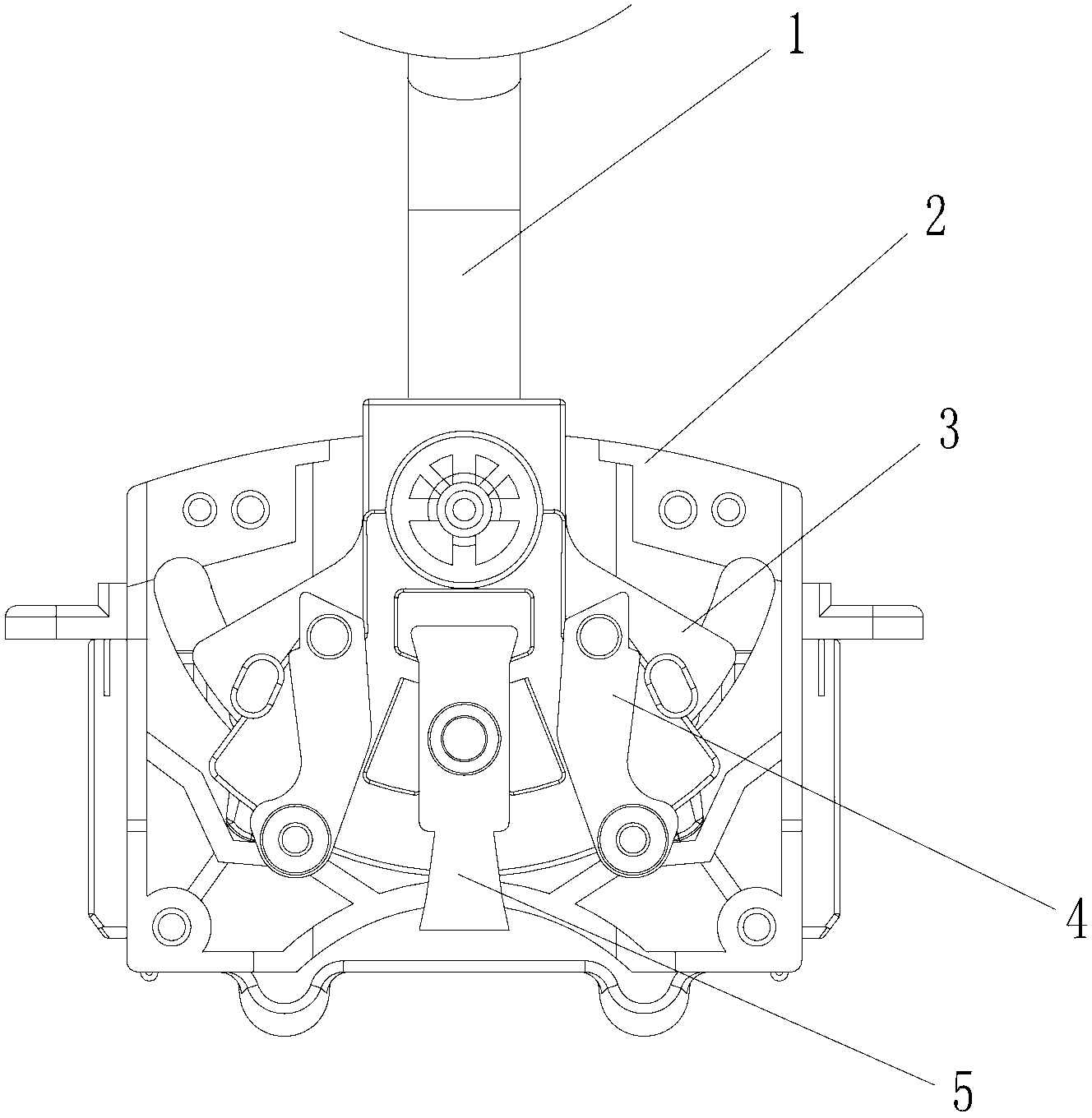

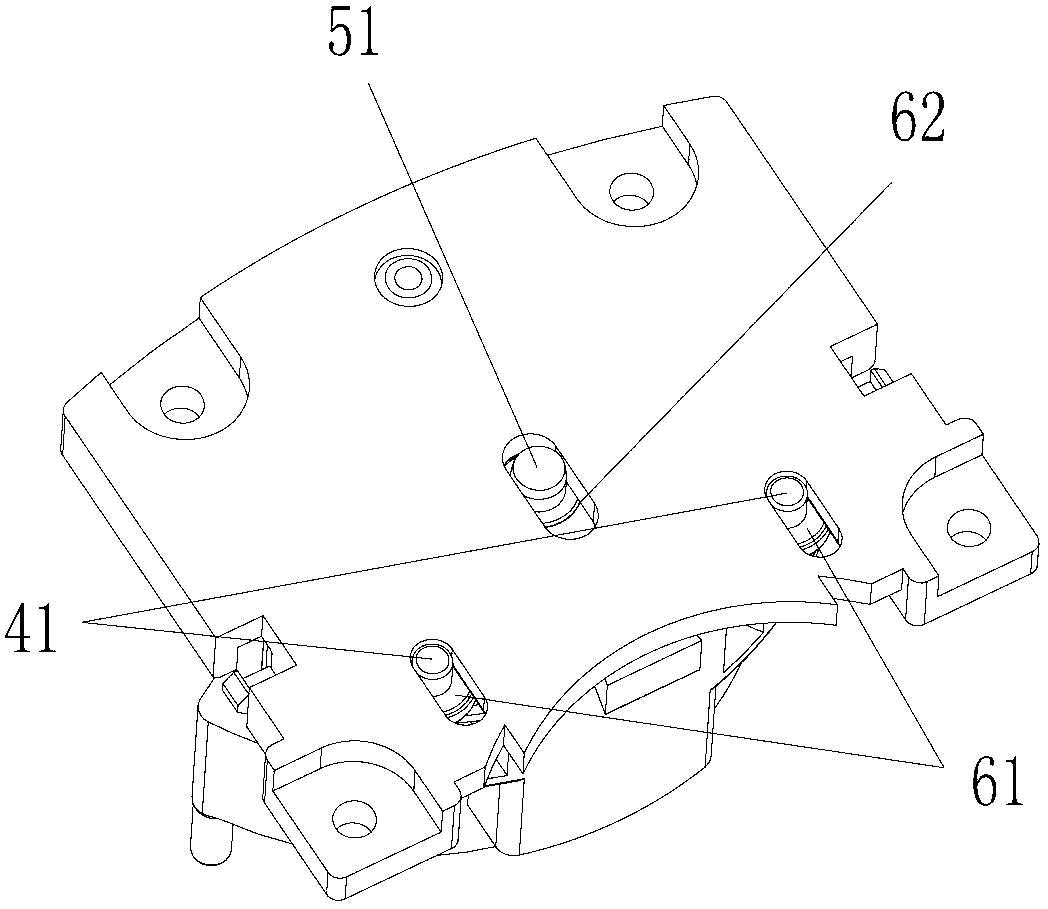

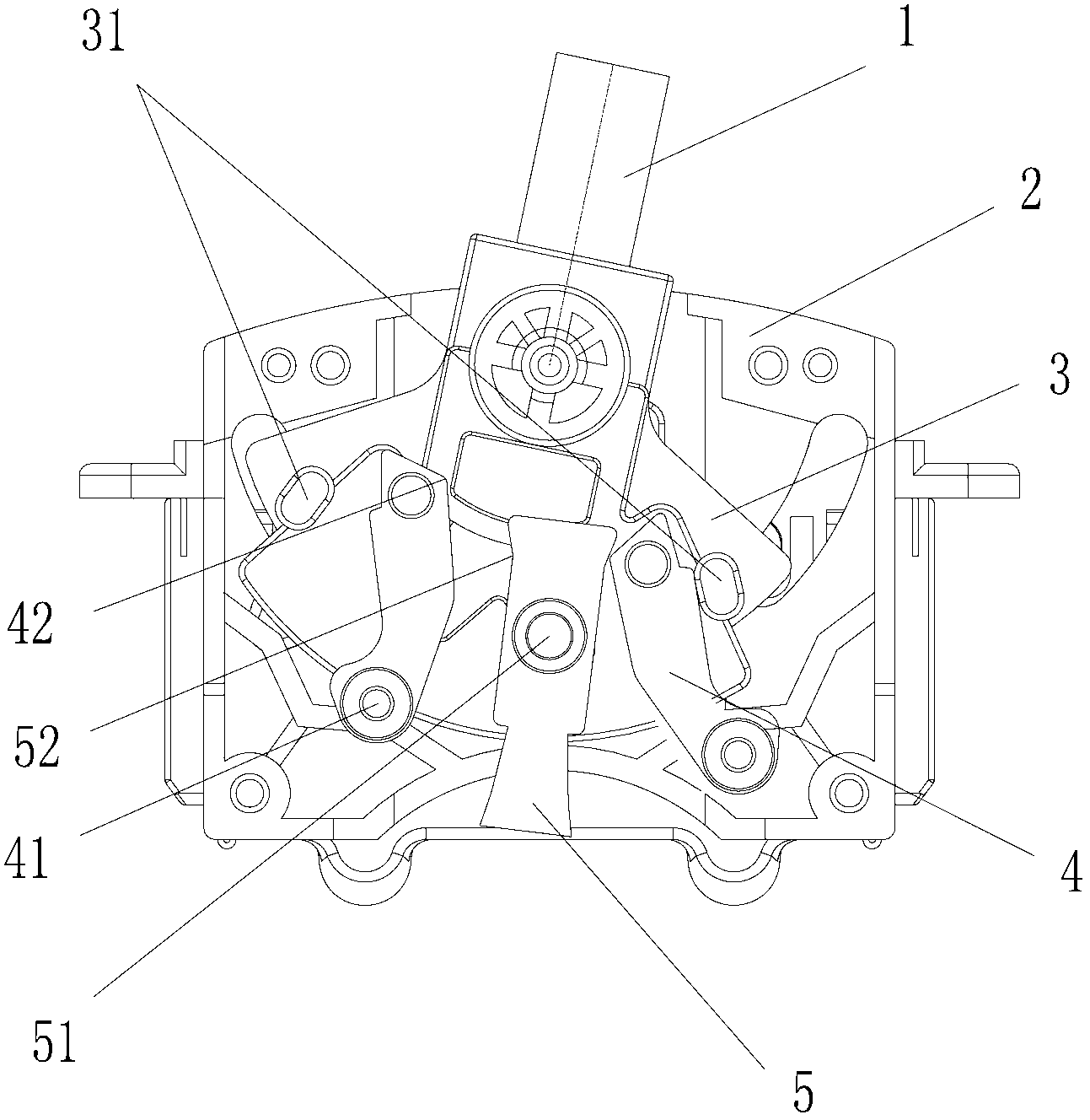

[0014] Please also refer to Figure 1 to Figure 3 , as shown in the figure, a car steering return structure, including a handle 1, a base 2, a shift fork 3 and an upper cover 6, the handle 1 is fixed on the shift fork 3 by screws, and the shift fork 3 is movably connected with the base 2 by pins , the return shift block 5 is placed on the fan-shaped groove of the shift fork 3, the upper cover 6 is press-fitted on the return shift block 5, and is fixedly connected with the base 2 by screws, and also includes the two sides of the return shift block 5 The movable block 4 is provided with a protrusion 42 for extending into the groove 52 on the return dial 5 . When the return toggle block 5 rotates to a larger angle, the protrusion 42 of the movable block 4 stretches into the groove 52 of the return toggle block, so that the return toggle block 5 will not come off from the original position.

[0015] see figure 2 , as shown in the figure, after the upper cover is closed, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com