System for automatically testing service life of probe

An automatic test system and probe technology, applied in measuring devices, measuring electrical variables, instruments, etc., can solve problems such as probe failure, and achieve the effect of accurate test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

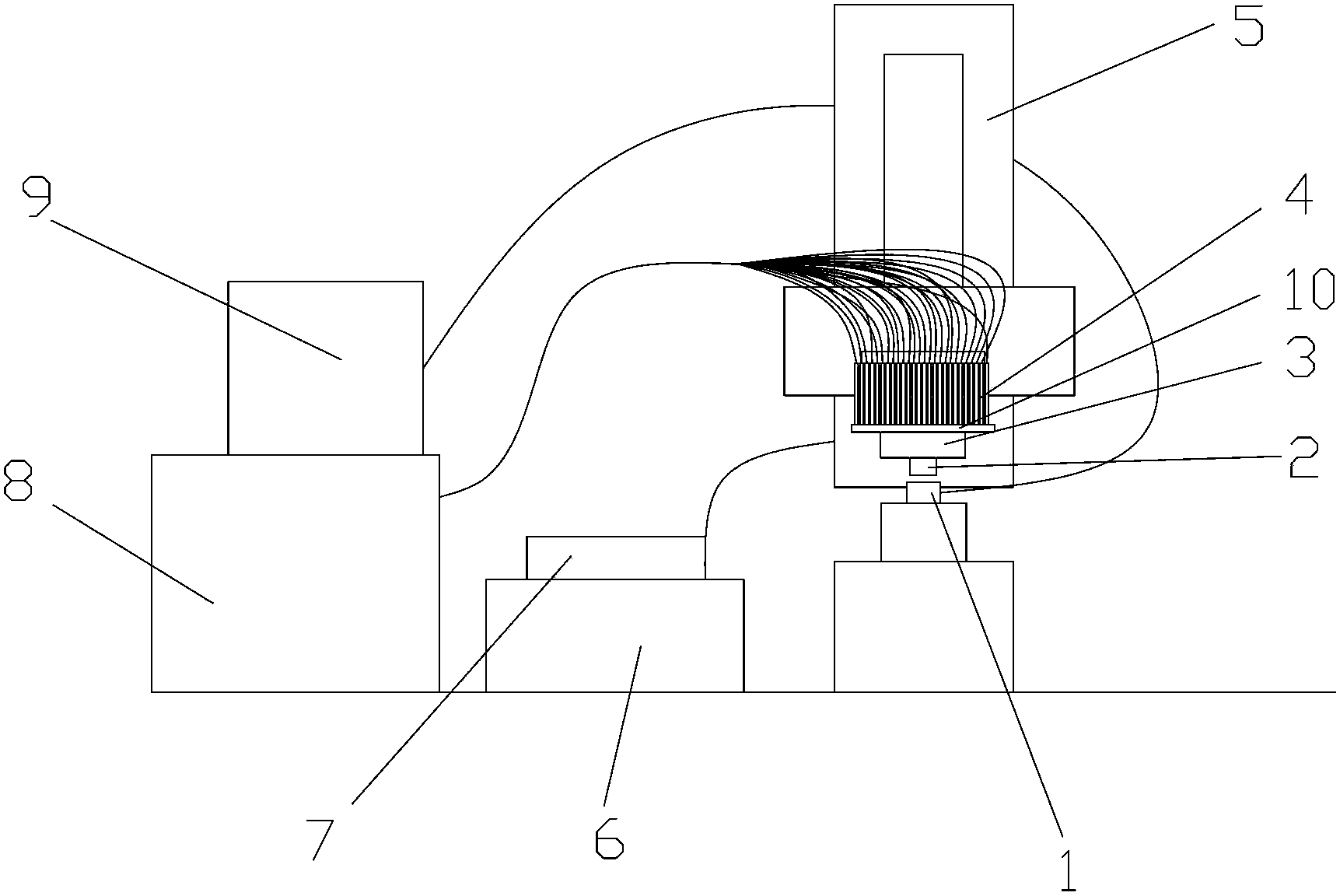

[0016] Such as figure 1 Shown: An automatic test system for probe life, such as figure 1 As shown, the high-frequency response force sensor 1 is placed on the platform, and the single probe or multiple probes 2 to be tested are loaded into the probe holder 3. According to the size of the probe 2, its diameter is generally 50-300 Micron, the probe holder 3 that fixes the probe 2 can fix one or more probes 2 in a probe holder 3 at the same time to meet the simultaneous measurement requirements of a single probe and multiple probes. The circuit board 10 on the fixture 3 leads the electrode of the probe 2 out, and then connects with the four-wire tester 8 through the probe electrode lead-out line 4 connected to the circuit board 10, and collects the contact of the probe 2 through the four-wire tester 8. The change of resistance, the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com