Connecting shaft structure of external work output connection device of turbine expansion engine

A turbo expander and output connection technology, which is applied to the sealing of the engine, mechanical equipment, engine components, etc., can solve problems that have not been seen in patent and non-patent literature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

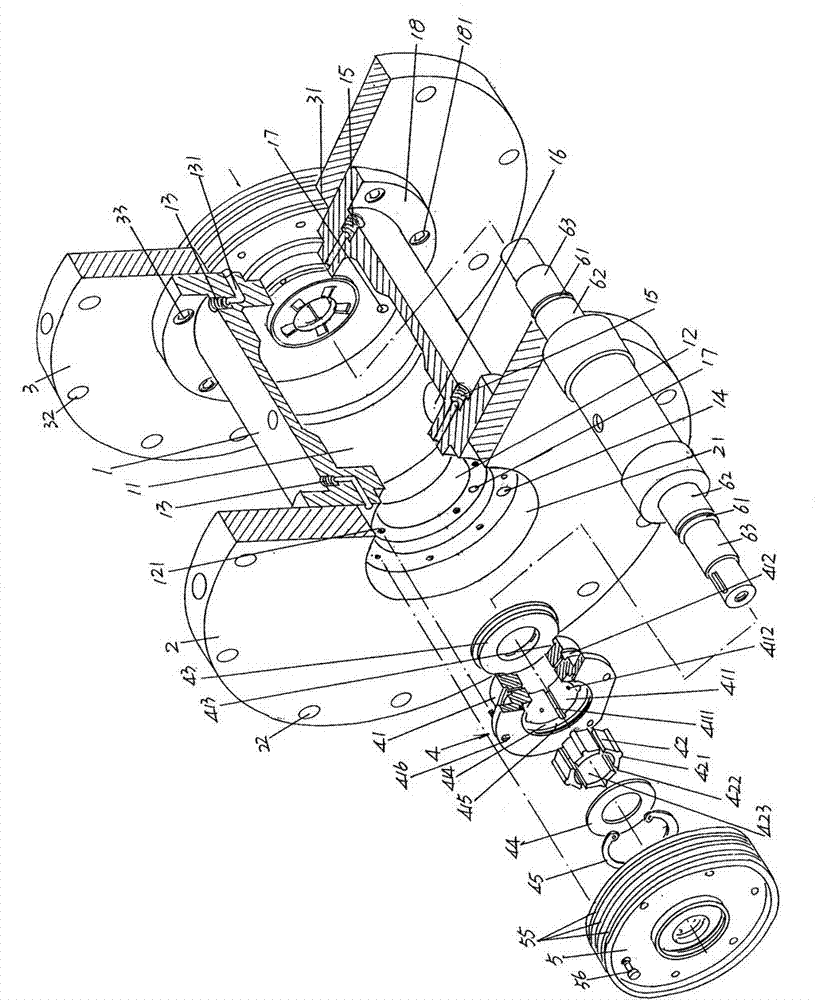

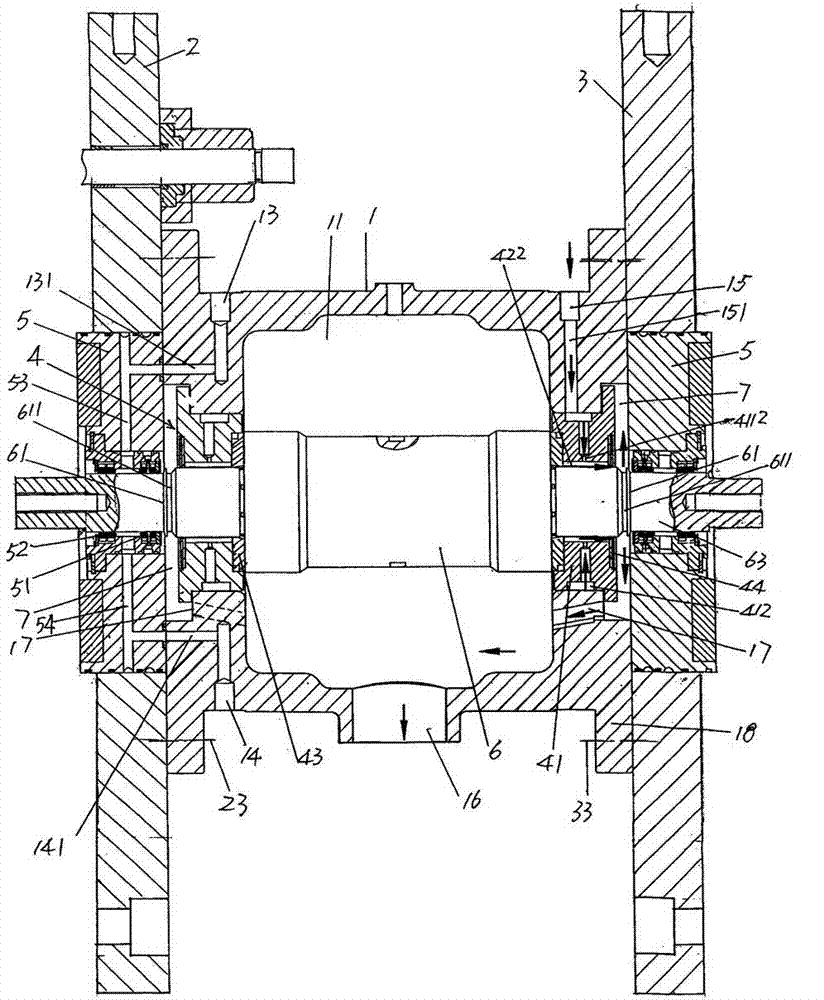

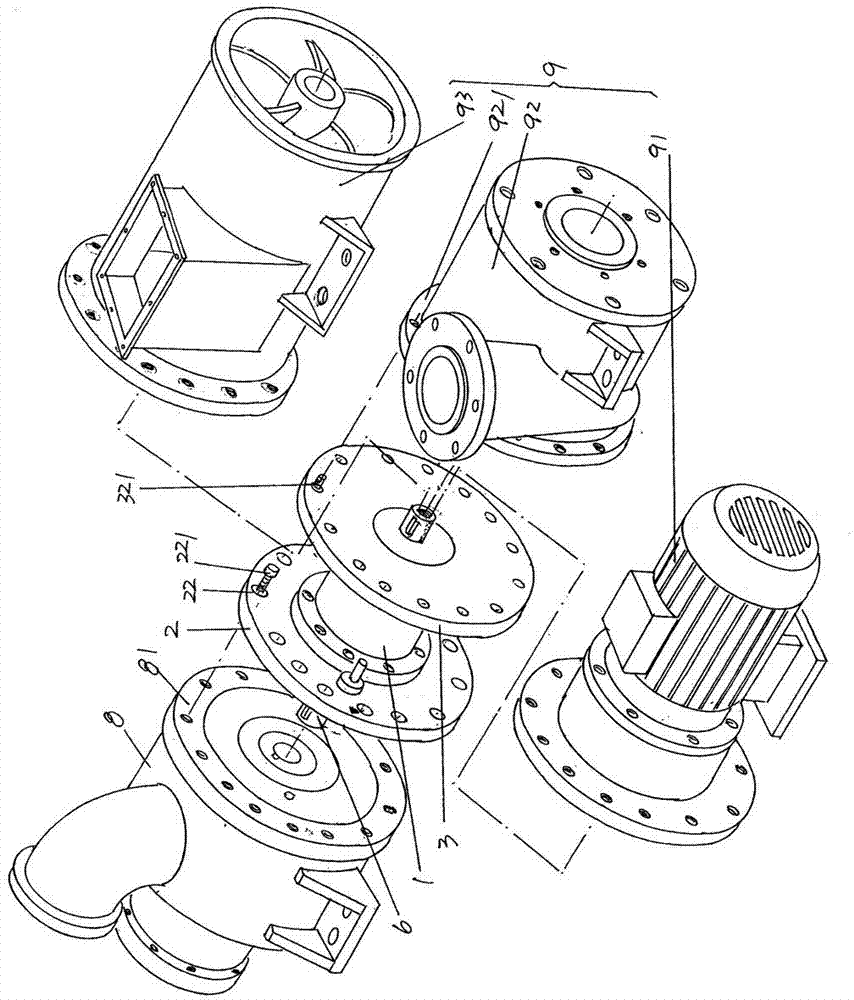

[0019] See figure 1 and figure 2 , a connection sleeve 1 of the external power output connection device of the turbo expander is given. The two ends of the connection sleeve 1, namely the left and right ends, are respectively expanded with a fixed flange edge 18, and each fixed flange A group of flange fixing holes 181 are provided at intervals on the side 18 . An air inlet 13 is provided at both ends of the connecting sleeve 1 and near the corresponding fixed flange edge 18 respectively. At both ends of one side, the pressure air or compressed air from the air source device such as air compressor or booster pump is introduced into the air inlet 13 through the pipeline, and each air inlet 13 has a The air-leading channel 131 is directed toward the sealing ring seat 5 which will be described below, that is to say, the leading air channel 131 extends in the direction of the sealing ring seat 5 . Also, on the connection sleeve 1 and at both ends of the downward position i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com