Small inclined tuyere sleeve

A technology of small tuyere and oblique tuyere, which is applied in the direction of the tuyere, can solve the problem of easy wear and tear of the small tuyere of the oblique tuyere, and achieve the effect of reducing the shutdown rate, avoiding wear and tear, and reducing the number of damages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

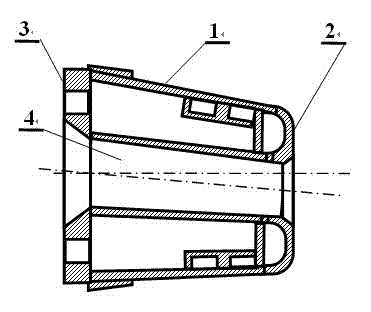

[0008] Such as figure 1 As shown, a small tuyere cover includes a small tuyere body 1, the two ends of the small tuyere body 1 are respectively fixed with a front end face 2 and a rear end face 3, the front end face 2 is parallel to the rear end face 3, and the small tuyere cover The body 1 is provided with a hot air channel 4 , and the center line of the hot air channel 4 forms an included angle with the center line of the rear end surface 3 .

[0009] The hot air channel 4 is inclined downwards, and its rear end face 3 and front end face 2 are parallel to each other. Therefore, the upper part of the front end face 2 does not appear to protrude into the furnace, which can reduce or even avoid the wear of the upper part of the front end face 2, and can reduce the inclination. The number of damaged tuyeres is conducive to reducing the shutdown rate of the blast furnace, which is conducive to the energy saving and emission reduction of the blast furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com