Method for preparing hydrophobic silica aerogel with low cost

A silicon dioxide and hydrophobic technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of increased production costs, large energy consumption, cumbersome processes, etc., achieve low cost, improve thermal insulation performance, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

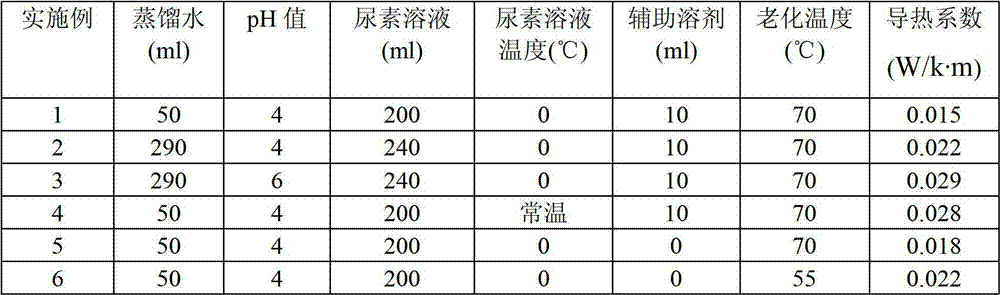

Embodiment 1

[0022] Mix 50 milliliters of distilled water, 6.0 grams of dodecyltrimethylammonium chloride, and 260 milliliters of methyltrimethoxysilane. After stirring and mixing for 20 minutes, adjust the pH value to 4 with acetic acid, add 10 milliliters of methanol and stir for 10 minutes After that, it was left still at 25° C. for 60 minutes.

[0023] Mix 200 ml of urea solution with a mass concentration of 0.2 g / ml and temperature down to about 0°C into the above solution, stir and mix thoroughly, and then stand at 25°C for 12 hours to form a sol.

[0024] A gel was formed after aging the above sol at 70°C for 36 hours. Then, the formed gel was solvent exchanged and washed with methanol at 55° C. for 4 times, each time for 12 hours.

[0025] Subsequently, the gel was dried in a normal pressure environment at 50° C. for 24 hours to obtain a silica airgel product.

[0026] After testing, the thermal conductivity of the above silica airgel product at 25°C is 0.015W / k·m.

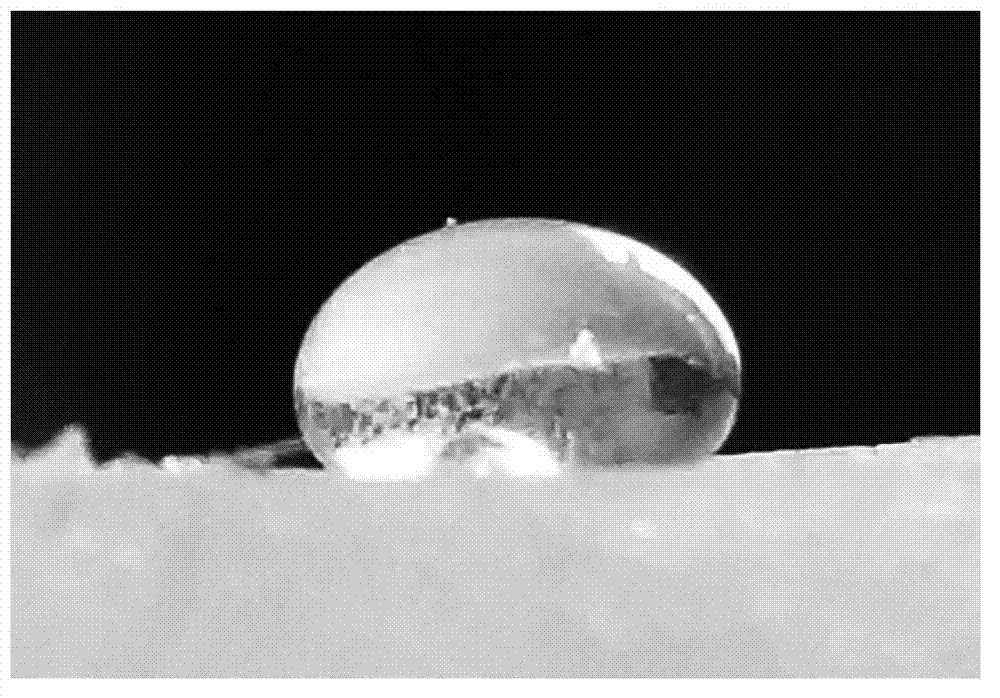

[0027] fig...

Embodiment 2

[0029] Mix 290 ml of distilled water, 6.0 g of dodecyltrimethylammonium chloride, and 260 ml of methyltrimethoxysilane. After fully stirring and mixing for 20 minutes, adjust the pH value to 4 with acetic acid, add 10 ml of methanol and stir for 10 minutes After that, it was left still at 25° C. for 60 minutes.

[0030] Mix 240 ml of urea solution with a mass concentration of 0.2 g / ml and temperature down to about 0°C into the above solution, stir and mix thoroughly, and then stand at 25°C for 12 hours to form a sol.

[0031] A gel was formed after aging the above sol at 70°C for 36 hours. Then, the formed gel was solvent exchanged and washed with methanol at 55° C. for 4 times, each time for 12 hours.

[0032] Subsequently, the gel was dried in a normal pressure environment at 50° C. for 24 hours to obtain a silica airgel with strong hydrophobicity and excellent thermal insulation effect. The thermal conductivity at 25°C can reach 0.022W / k·m.

Embodiment 3

[0034] Mix 290 ml of distilled water, 6.0 g of dodecyltrimethylammonium chloride, and 260 ml of methyltrimethoxysilane, stir and mix thoroughly for 20 minutes, adjust the pH value to 6 with acetic acid, add 10 ml of methanol and stir for 10 minutes After that, it was left still at 25° C. for 60 minutes.

[0035] Mix 240 ml of urea solution with a mass concentration of 0.2 g / ml and temperature down to about 0°C into the above solution, stir and mix thoroughly, and then stand at 25°C for 12 hours to form a sol.

[0036] A gel was formed after aging the above sol at 70°C for 36 hours. Then, the formed gel was solvent exchanged and washed with methanol at 55° C. for 4 times, each time for 12 hours.

[0037] Subsequently, the gel was dried in a normal pressure environment at 50° C. for 24 hours to obtain a silica airgel with strong hydrophobicity and excellent thermal insulation effect. The thermal conductivity at 25°C can reach 0.029W / k·m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com