Easily-torn flanged compound film with good transparency and preparation method thereof

A composite film, transparency technology, applied in chemical instruments and methods, synthetic resin layered products, flexible coverings, etc., can solve problems such as poor transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

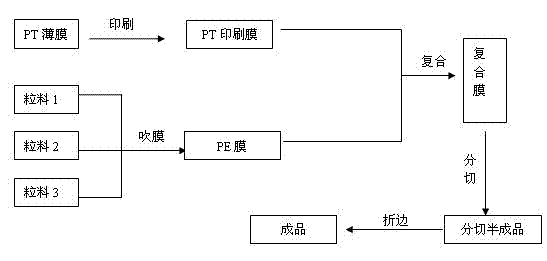

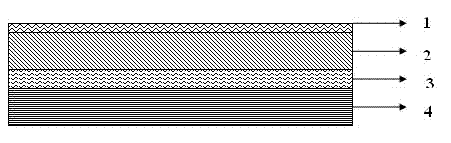

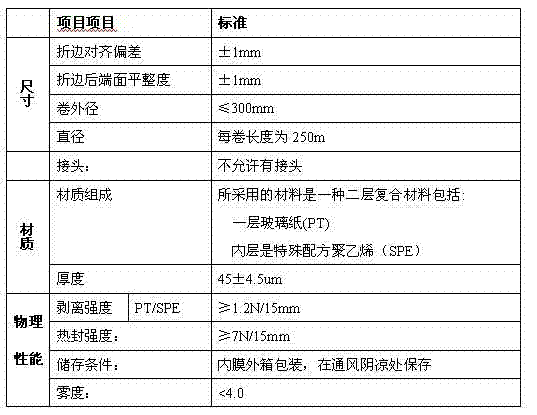

[0034] a. Cellophane (PT) film layer printing process: at 50-60°C, the PET film is printed to form a cellophane (PT) printing film;

[0035] b. The preparation process of three-layer co-extruded polyethylene (PE) film: mix low-density polyethylene and linear low-density polyethylene in a weight ratio of 1:2, and then place them in the three layers of the three-layer co-extruded film blowing machine. In the barrel, after being extruded by an extruder, it is made into a composite polyethylene film.

[0036] c. Dry compounding: Glue the cellophane (PT) film that has been printed with patterns and texts, and compound it with polyethylene film through a dry compounding machine. The glue used is polyurethane glue, and the operating concentration of the glue is controlled at No. 3 Zahn Cup 16 -17 seconds, the coating amount is 3.5-3.5gsm, and the composite tension is controlled at 35%.

[0037] d. Slitting: According to the different width, length and specifications required by the...

Embodiment 2

[0040] Except c, dry composite: the composite tension is controlled at 40%; e, the hemming tension is controlled at 50%, the rest are the same as in Example 1.

Embodiment 3

[0042] Except c, dry composite: the composite tension is controlled at 40%; e, the hemming tension is controlled at 45%, the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Coefficient of friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com