Chocolate melting oven

A chocolate and melting furnace technology, which is applied in the field of food processing, can solve the problems of poor chocolate taste, poor temperature control, and chocolate melting, and achieve the effects of temperature balance and stability, good uniformity and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

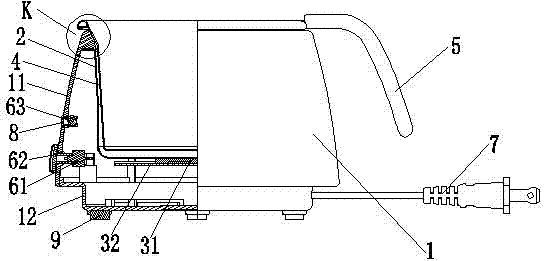

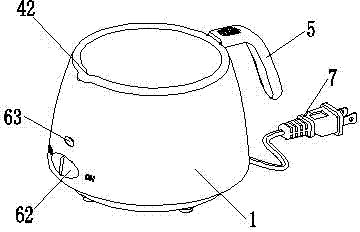

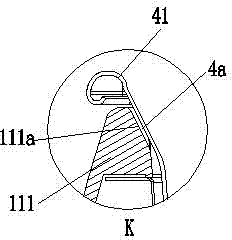

[0025] Figures 1 to 8 Shown is the structural representation of the present invention.

[0026] The reference signs therein are: furnace shell 1, outer shell 11, knob hole 11a, display hole 11b, annular support boss 111, tapered support slope 111a, base 12, crimping post 121, aluminum-coated tube 2, heating Cavity 2a, PTC ceramic heating element 31, heating element fixing piece 32, aluminum pot 4, outer cone surface 4a, flange edge 41, collector 42, connecting lug 43, handle 5, horizontal connecting portion 51, handle portion 52. Slide switch 61, switch knob 62, power working indicator light 63, power cord 7, pressure plate 71, lampshade 8, rubber foot pad 9.

[0027] Figure 1 to Figure 8 It is a structural schematic diagram of the present invention. It can be seen from the figure that a chocolate melting furnace of the present invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com