Quickly disintegrated imidacloprid and emamectin benzoate water dispersible granules and preparation method thereof

A technology of imidacloprid first dimension and dispersible granules, applied in the field of pesticides, can solve problems such as poor disintegration of water dispersible granules, and achieve the effects of fast disintegration and dispersion in water, high dispersion and suspension rate, and small particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1 4.5% imidacloprid+0.5% emamectin emamectin saline dispersible granules and preparation method thereof

[0017] The components of the formula and their mass percentages are: 96.5% imidacloprid technical 4.7%, 72.0% emamectin benzoate technical 0.7%, dispersant 8.0%, wetting agent 2.0%, kaolin 20.0%, corn starch 20.0%, Silica 9.0%, white carbon black 35.6%.

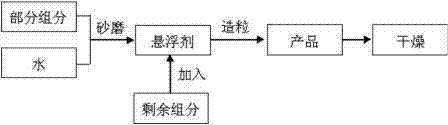

[0018] The preparation method of this water-dispersible granule is:

[0019] Put 4.7g of 96.5% imidacloprid technical medicine, 0.7g of 72.0% emamectin benzoate technical medicine, 8.0g of dispersant, 2.0g of wetting agent, 20.0g of kaolin, 23.0g of white carbon black, and 41.6g of water into a sand mill Sand milling until the particle size is below 5 μm, then add 9.0 g of jet-milled silicon dioxide, 20.0 g of corn starch, and 12.6 g of white carbon black, stir evenly, extrude and granulate on the extrusion equipment, and dry After that, it is 4.5% imidacloprid + 0.5% emamectin benzoate saline dispersible...

Embodiment 2

[0021] Example 2 9.0% imidacloprid+1.0% emamectin emamectin saline dispersible granules and preparation method thereof

[0022] The components of the formula and their mass percentages are: 96.5% imidacloprid technical 9.4%, 72.0% emamectin benzoate technical 1.4%, dispersant 8.0%, wetting agent 2.0%, kaolin 10.0%, corn starch 20%, White carbon black 49.2%.

[0023] The preparation method of this water-dispersible granule is:

[0024] 9.4g of 96.5% imidacloprid, 1.4g of 72.0% emamectin benzoate, 8.0g of dispersant, 2.0g of wetting agent, 10.0g of kaolin, 20g of cornstarch, and 49.2g of water, put them into a sand mill for sanding, Sand mill until the particle size is below 5 μm, then add 49.2 g of white carbon black, stir evenly, extrude and granulate on the extrusion equipment, and after drying, it will be 9.0% imidacloprid + 1.0% emamectin benzoate saline dispersible granules.

[0025] After testing, the number of disintegration of the water-dispersible granules was 2 time...

Embodiment 3

[0026] Example 3 18.0% imidacloprid+2.0% emamectin emamectin saline dispersible granules and preparation method thereof

[0027] The components of the formula and their mass percentages are: 96.5% imidacloprid technical 18.8%, 72.0% emamectin benzoate technical 2.8%, dispersant 10.0%, wetting agent 2.0%, kaolin 10.0%, corn starch 20%, Sodium sulfate 15.0%, white carbon black 21.4%.

[0028] The preparation method of this water-dispersible granule is:

[0029] 96.5% imidacloprid technical 18.8g, 72.0% emamectin benzoate technical 2.8g, dispersant 10.0g, wetting agent 2.0g, kaolin 10.0g, water 56.4g, put into the sand mill and grind until the grain diameter below 5μm, then add 20.0g of cornstarch, 15.0g of sodium sulfate, 21.4g of white carbon black, stir evenly, extrude and granulate on extrusion equipment, after drying, it will be 18.0% imidacloprid + 2.0% emamectin benzoate salt water Dispersible granules.

[0030] After testing, the number of disintegration of the water-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com