A buoyant multifunctional composite material for effective removal of organic compounds in water and wastewater

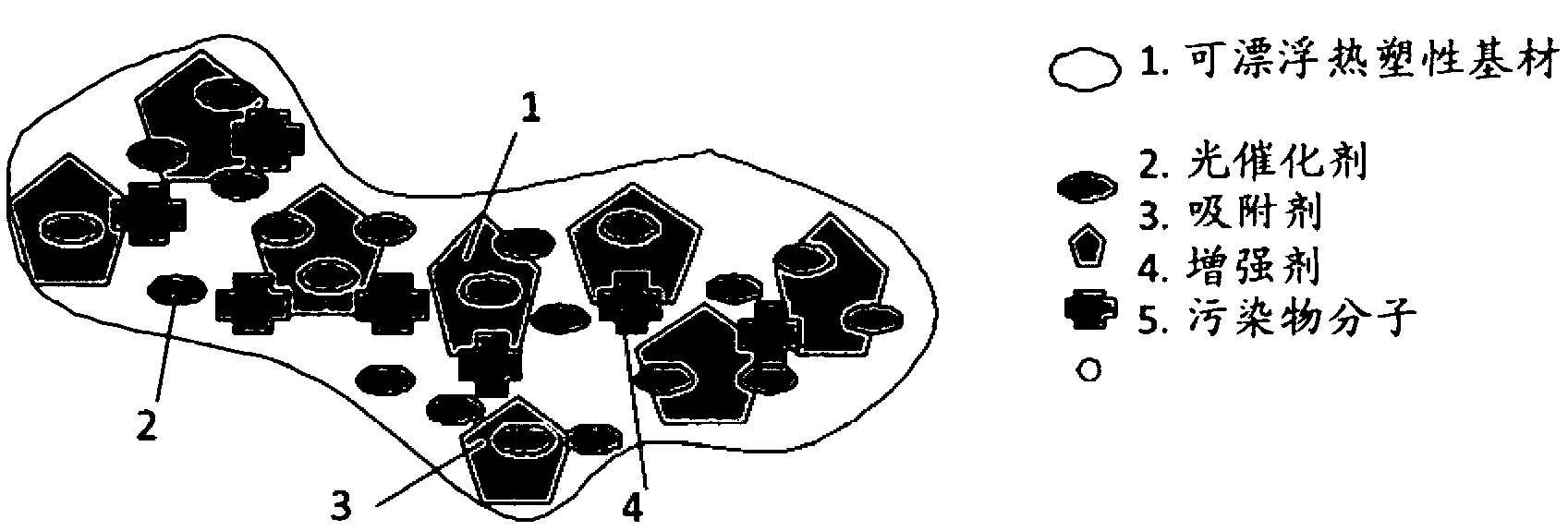

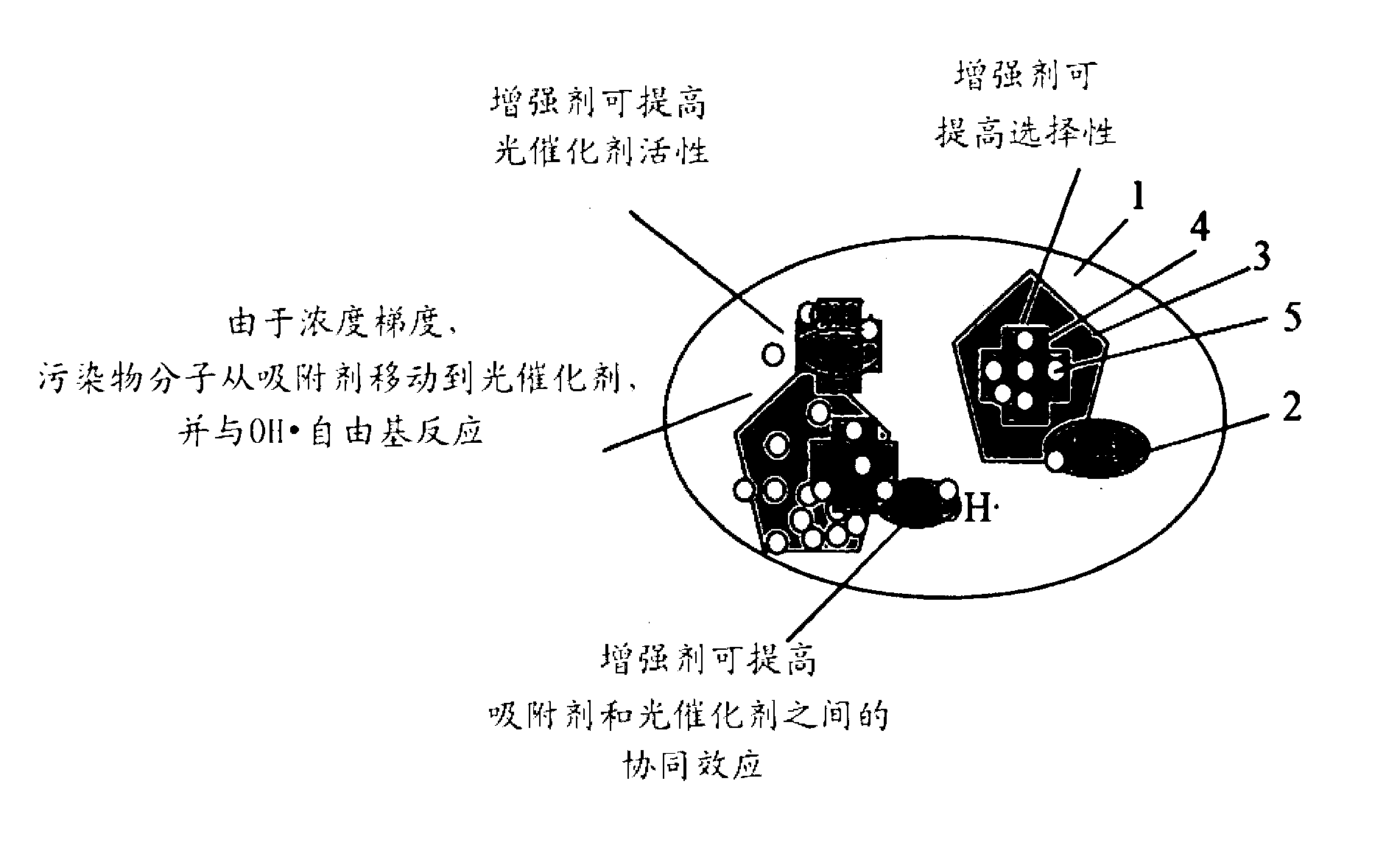

A technology of organic compounds and composite materials, applied in the field of floating multifunctional composite materials for effectively removing organic compounds in water and wastewater, can solve problems such as low utilization rate, reduce the performance of adsorbents and photocatalysts, and achieve cost-effective , less capital and operating costs, the effect of high mass transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A 5 g amount of 25 nm TiO 2 The granules were treated in a 2 g / L salicylic acid solution for 30 minutes and dried in an oven at 100° C. for 2 hours. Then, the treated TiO 2 The particles were mixed with 0.05 g of multi-walled carbon nanotubes (diameter 110-170 nm, length 5-9 μm) and heated in an oven at 200° C. for 2 hours. Then, 10 grams of 100-mesh activated carbon particles were mixed with TiO 2 Mix with the mixture of carbon nanotubes, and then pack all the components in a 250 mL reactor. The mixture in the reaction vessel was preheated to and maintained at 200°C with a hot plate heater and stirred with a mechanical mixer. Then, an amount of 30 grams of polypropylene (PP) having a diameter of about 4 mm was added to the reactor. The mixture in the reactor was further heated with stirring to increase and maintain the temperature to 160°C. The process continued for another 3 minutes. Then, the PP particles and the small-sized powder mixture are sufficiently fixe...

Embodiment 2

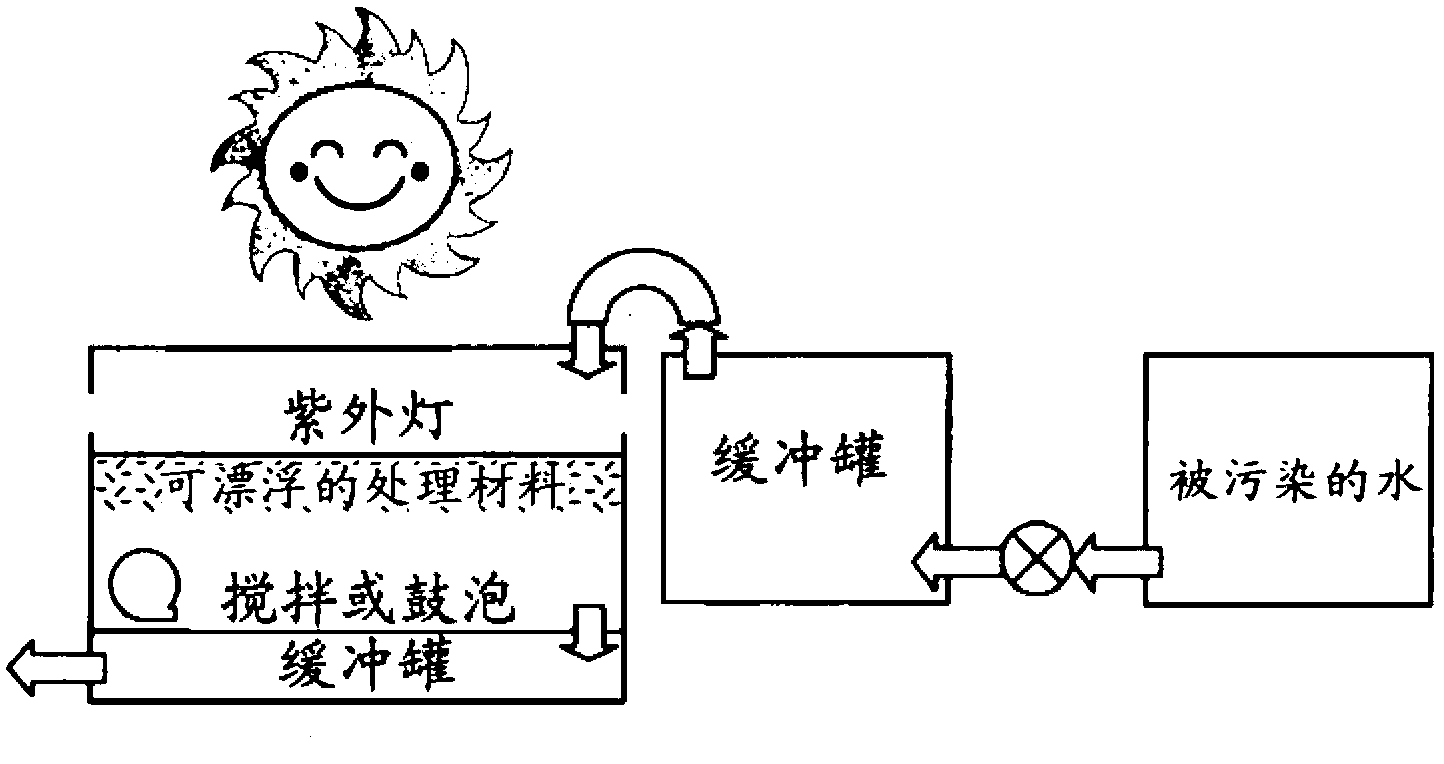

[0041] 50 g P25TiO 2 (AEROXIDE, Degussa) was mixed with 50 g of 100 mesh activated carbon particles in an 800 mL reactor to prepare a multifunctional floatable photocatalyst. The mixture was preheated to and maintained at 185°C with a hot plate heater and stirred with a mechanical mixer. Next, 50 polypropylene (PP) pellets with a diameter of about 4 mm were added to the reactor. The mixture was further heated with stirring for 10 minutes. Make PP particles covered with TiO 2 and activated carbon granules. The treated PP particles were then collected and washed with ethanol and water. The washed particles were added to a 300 mL glass beaker along with 300 mL of 10 ppm phenol solution. The glass beaker was irradiated with a 150W xenon lamp with a beam diameter of 3". The air diffuser was used to introduce 1.5 liters of air per minute into the phenol solution. The phenol concentration was analyzed using an HPLC instrument with a C18 column. As Figure 4 As shown, the phenol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com