Ceramic silicon rubber insulation medium-voltage fire-resistant cable with rated voltage of 6-35kV and machining process thereof

A ceramic silicone rubber, 6kv-35kv technology, applied in the direction of power cable with shielding layer/conductive layer, cable/conductor manufacturing, circuit, etc., can solve the problem that the fire-resistant cable cannot last for a long time, manufacturing cost, outer diameter , heavy weight, and complex structure of medium-voltage fire-resistant cables, etc., to achieve the effects of light weight, low manufacturing cost, and long fire-resistant time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

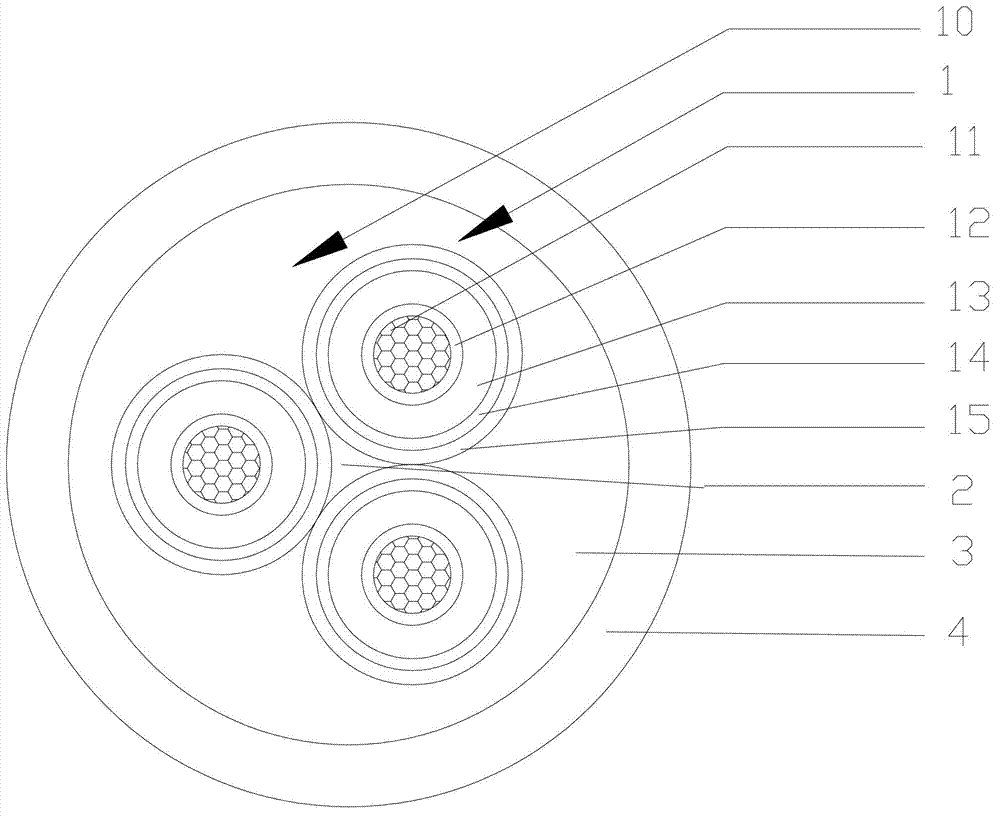

[0030] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

[0031] see figure 1 As shown, a rated voltage of 6kV-35kV ceramic silicone rubber insulated medium voltage fire-resistant cable, including three wire cores 1 twisted together to form a cable core 10, a cushion layer 3 coated on the outside of the cable core 10, a coating The outer sheath 4 outside the cushion layer 3, the cushion layer 3 is a polyvinyl chloride inner liner, and the outer sheath 4 is a polyvinyl chloride sheath. In the cable core 10, three wire cores 1 are closely arranged along the circumferential direction. The central gap between multiple wire cores 1 is filled with halogen-free flame-retardant fillers 2, and each wire core 1 includes a conductor 11, a semi-conductive silicone rubber-based material wrapped on the outer surface of the conductor 11. Conductor shielding layer 12, ceramicized silicone rubber insulating layer 13 wrapped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com