Double-revolving-chamber caseless ammunition gun

A caseless bullet and chamber-rotating technology, which is applied in the field of firearms, can solve the problems of doubling shooting time, high temperature of the bullet chamber, difficult processing, etc., achieves the effect of improving accuracy and reliability, solving the effects of high temperature of the bullet chamber, low weight and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

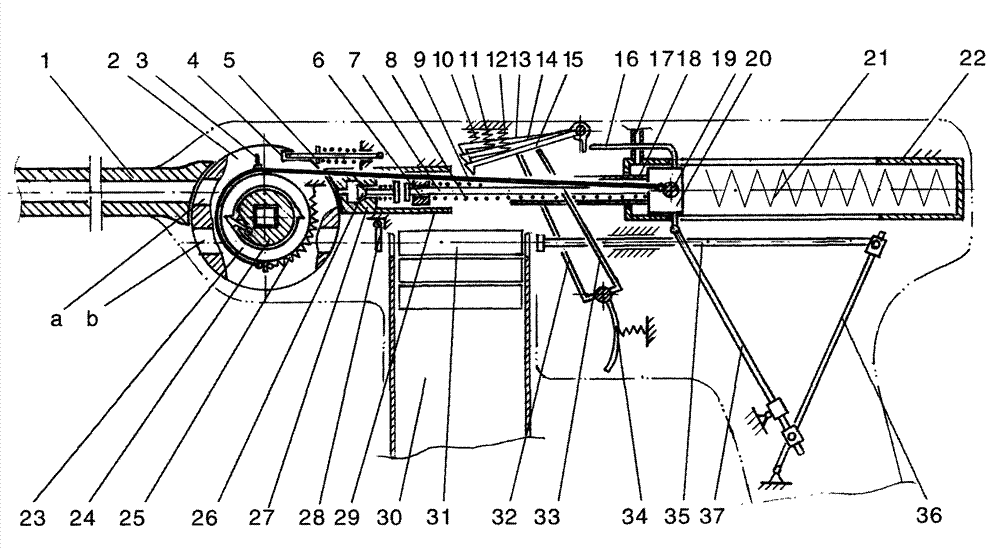

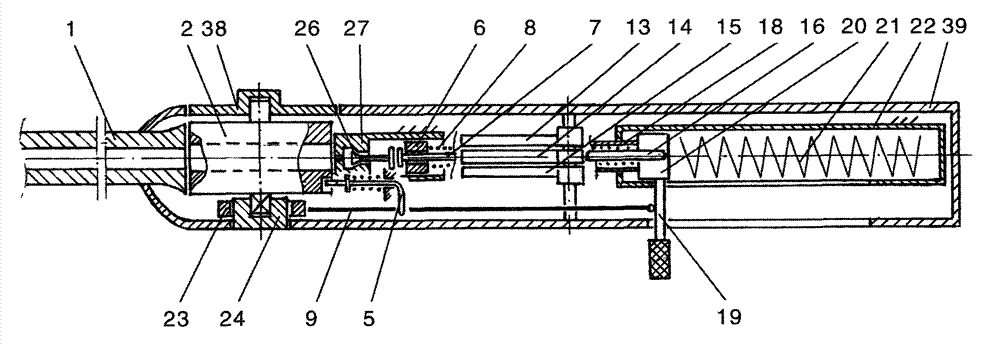

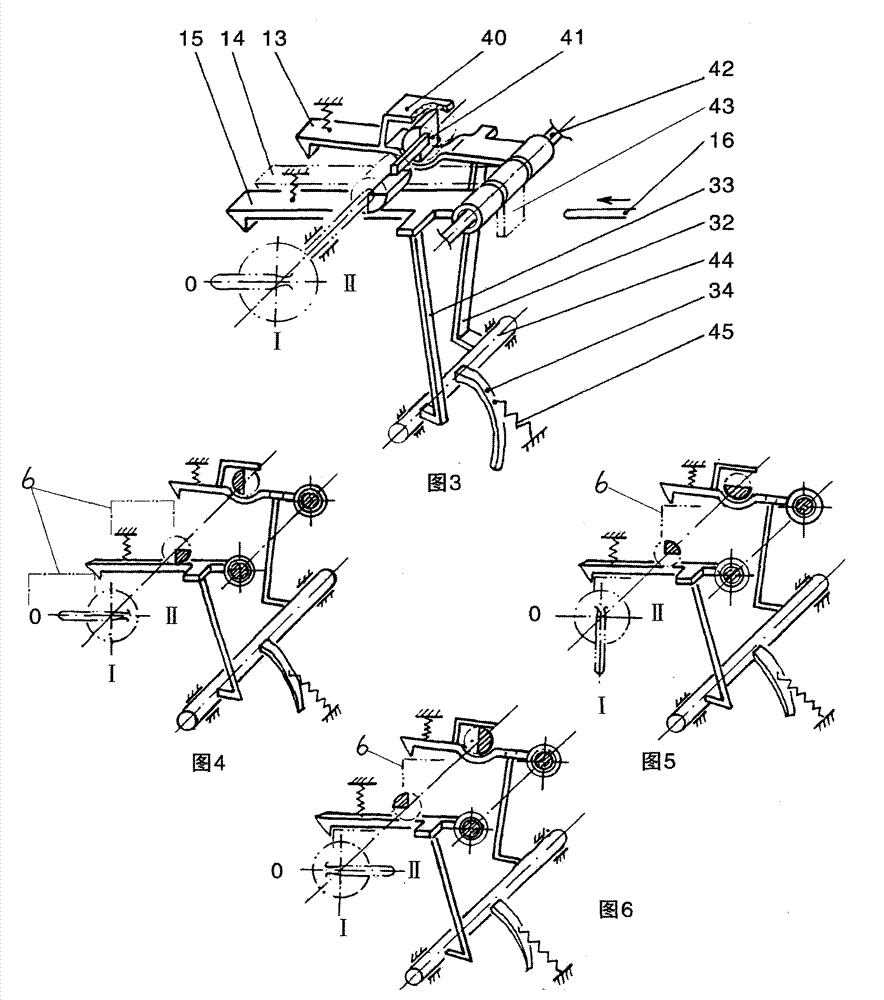

[0022] Example: such as figure 1 , figure 2 As shown, the double-rotating chamber caseless bullet gun of the present invention, the tail end of the gun barrel 1 is provided with a rotating shaft and a cylindrical rotating chamber body 2 that is perpendicular to the space of the gun barrel, and two bullet chambers parallel to the radial direction are arranged in it. a and b, one side of the rotating chamber body is supported on the chamber cover plate 38 articulated on the casing, and the other side is supported in the square inner hole of the ratchet shaft 24, and the ratchet shaft is supported on the casing 39, Ratchet 23 has back-moving spring 25, and one end of ratchet backguy 9 is affixed on the edge of ratchet, and the other end connects machine handle 19. Positioning pin 5 is set on the casing, dial pin 3 is established on the ratchet backguy, and positioning groove 4 is set on the rotating bullet body. There is a sealed dynamic fit between the rotating cartridge body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com