Novel refrigerator refrigerating evaporator

A technology for refrigerating evaporators and refrigerators, applied in evaporators/condensers, coolers, refrigerators, etc., can solve the problems of high power consumption and low heat transfer efficiency, and achieve low total cost, reasonable process design, and increased efficiency. The effect of a large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

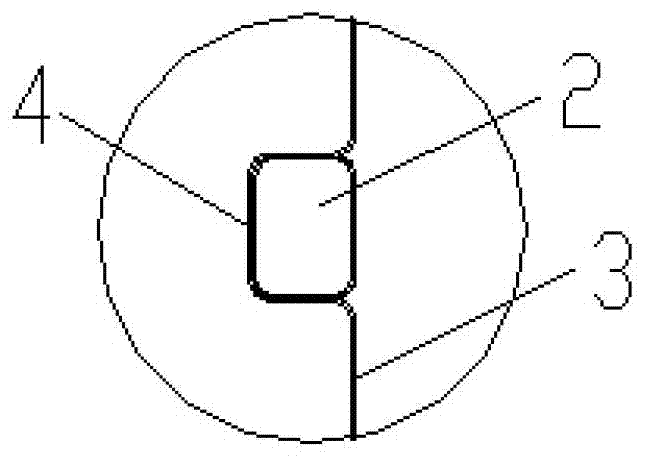

[0019] Such as figure 1 As shown in -4, the refrigerator refrigeration evaporator 1 of the present invention includes an H-shaped evaporation tube 2 and a heat transfer plate 3 . The heat transfer plate is preferably made of metal material, such as aluminum plate, but it is not necessarily the case. As long as it is a material with good thermal conductivity and is conducive to manufacturing, it will be beneficial to the refrigeration in the H-shaped evaporator tube. The cold energy of the agent is quickly and fully released, and transferred to the heat transfer plate, thereby exchanging heat with the air in the refrigerating room faster.

[0020] The H-shaped evaporating tube 2 is composed of a plurality of straight line pipes and curved pipes, which are arranged at certain intervals on the heat transfer plate. Among them, the straight line pipes and the curved pipes are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com