Toothed cable

A cable and rack technology, applied in the field of toothed cables, can solve problems such as easy to generate noise, achieve the effects of reducing sound, improving sliding performance, and preventing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

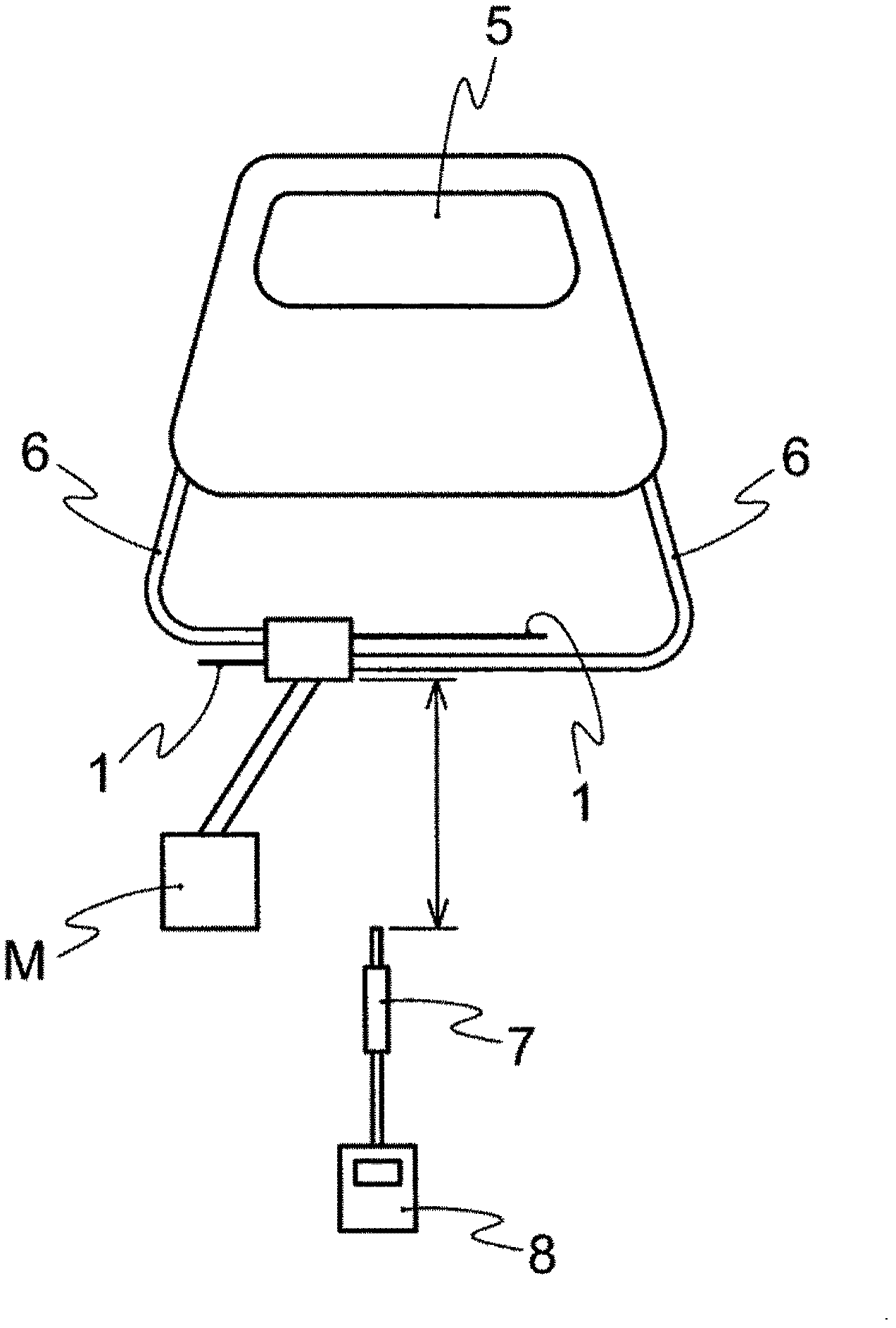

[0023] Hereinafter, the toothed cable of the present invention will be described in detail with reference to the drawings.

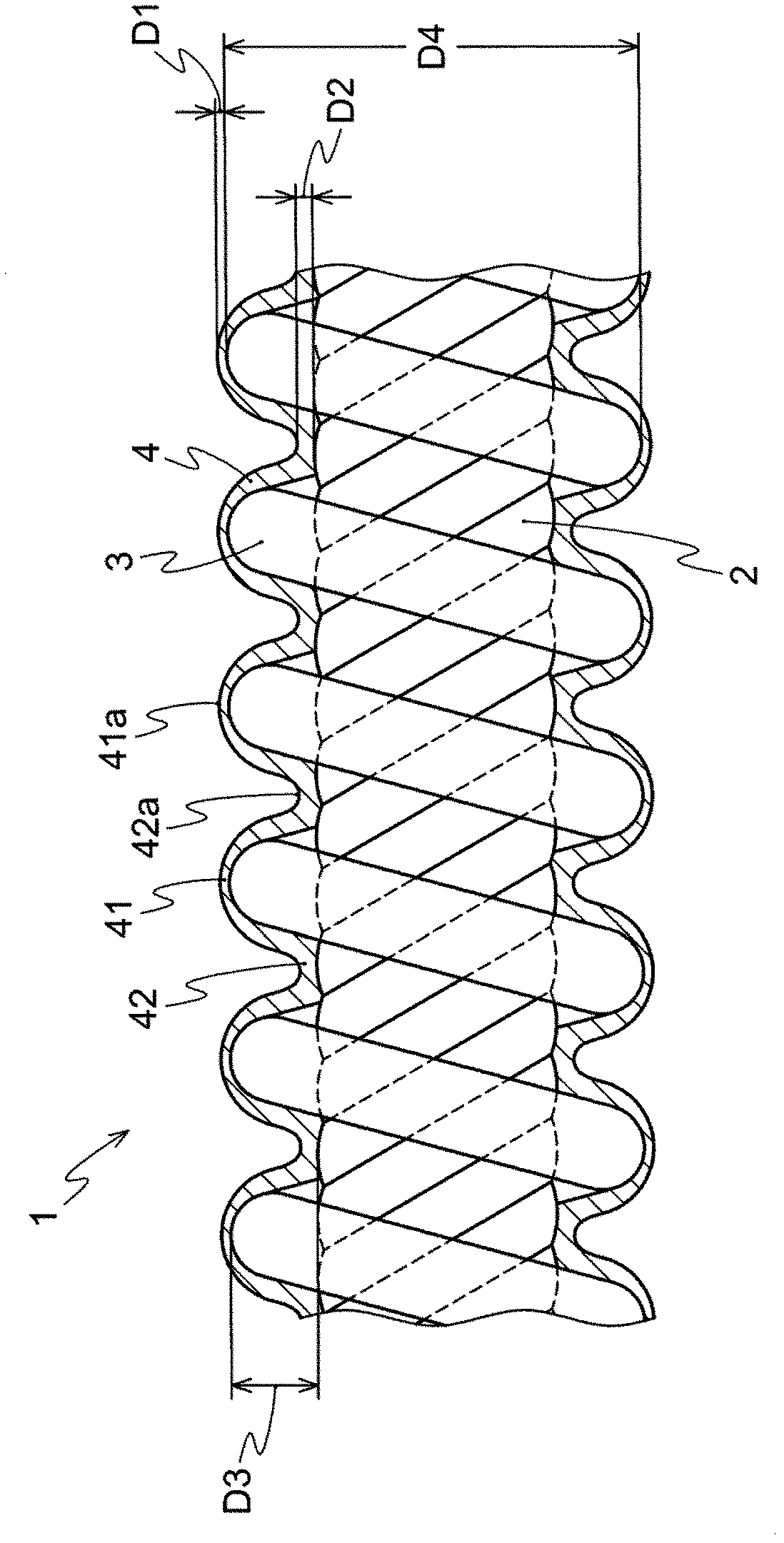

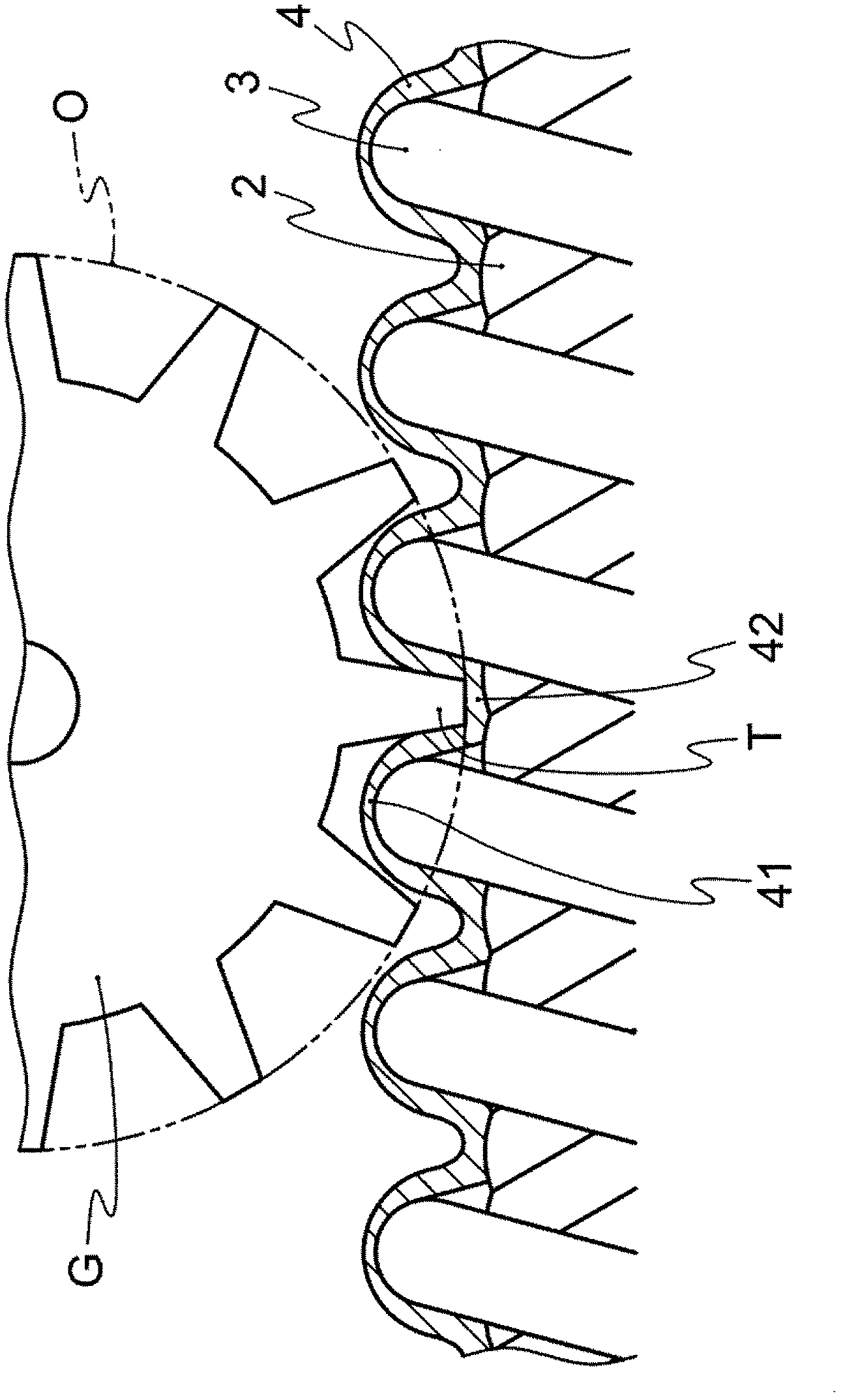

[0024] Such as figure 1 As shown, the toothed cable 1 of the present invention includes: a core cable 2; a rack 3 wound helically on the outer peripheral surface of the core cable 2; and a resin that continuously covers the core cable 2 and the rack 3 on the outer side (outer peripheral surface) of the covering layer 4.

[0025] As long as the core cable 1 has stretch resistance and torsion resistance, the same core cable as the core cable conventionally used for toothed cables can be used. In particular, although its structure is not limited, it can The core wire is formed by spirally winding a reinforcement layer composed of a plurality of metal wires around a core wire composed of a single metal wire, and then spirally winding another reinforcement layer composed of a plurality of metal wires around it. Cable 1.

[0026] The rack 3 is formed by he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com