Driving tool

A technology of driving tools and driving tools, applied in nailing tools, manufacturing tools, etc., can solve the problems of compressed air blowing, easy peeling, difficult rubber, etc., and achieve the effect of increasing sliding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described with reference to the drawings.

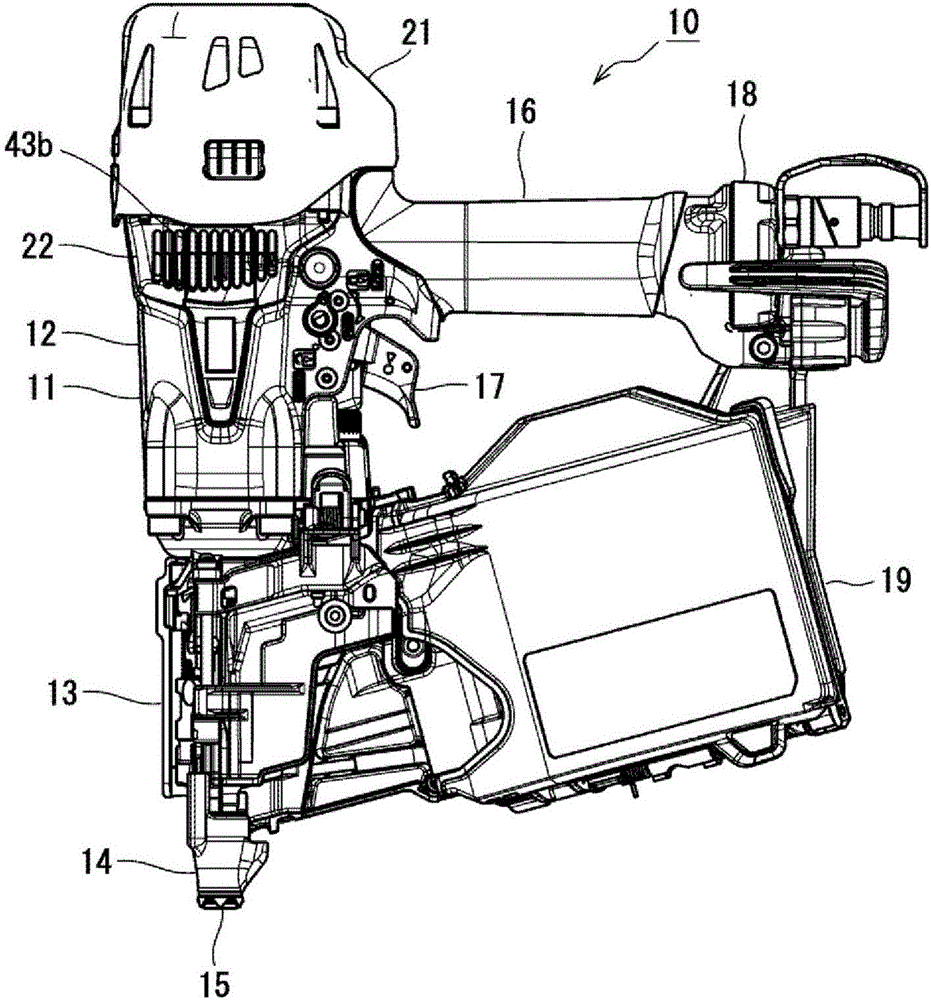

[0030] The driving tool 10 of this embodiment is a pneumatic driving tool 10 that uses compressed air to drive fasteners, such as figure 1 As shown, it is provided with: a tool body 11 with a machine head 13; and a silo 19 with the tool body 11 connected to it. A connecting fastener is stored in the bin 19, and the connecting fastener is drawn in the direction of the nose 13 and used.

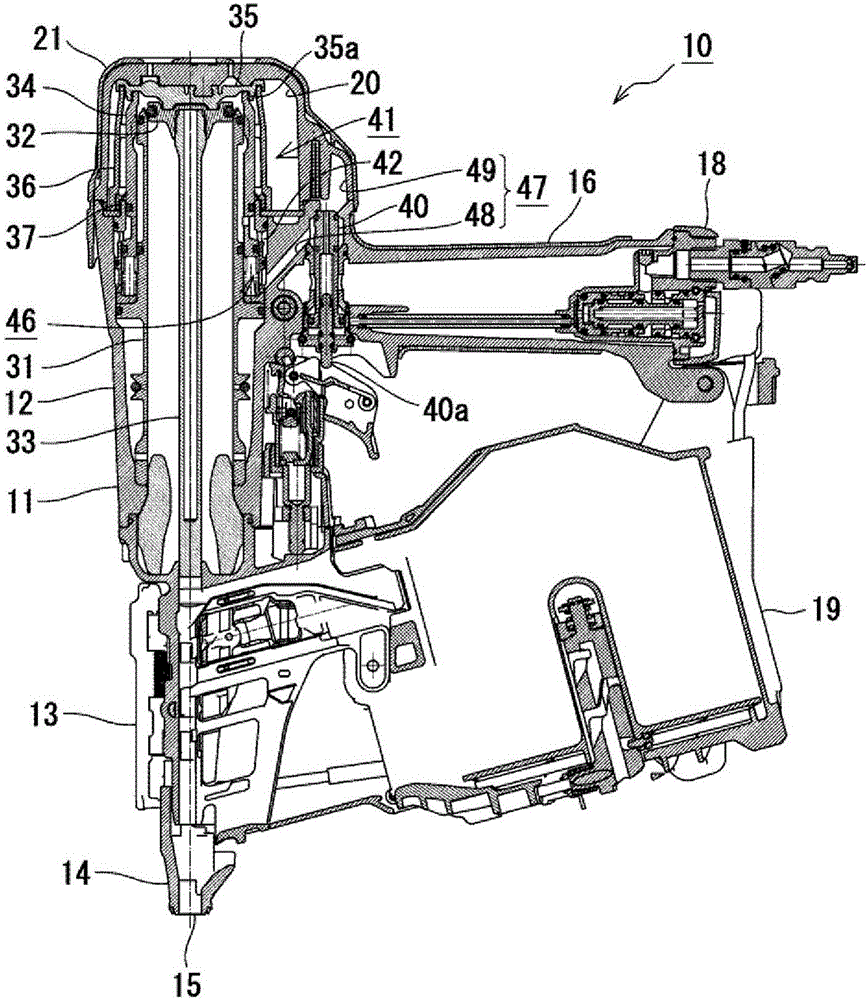

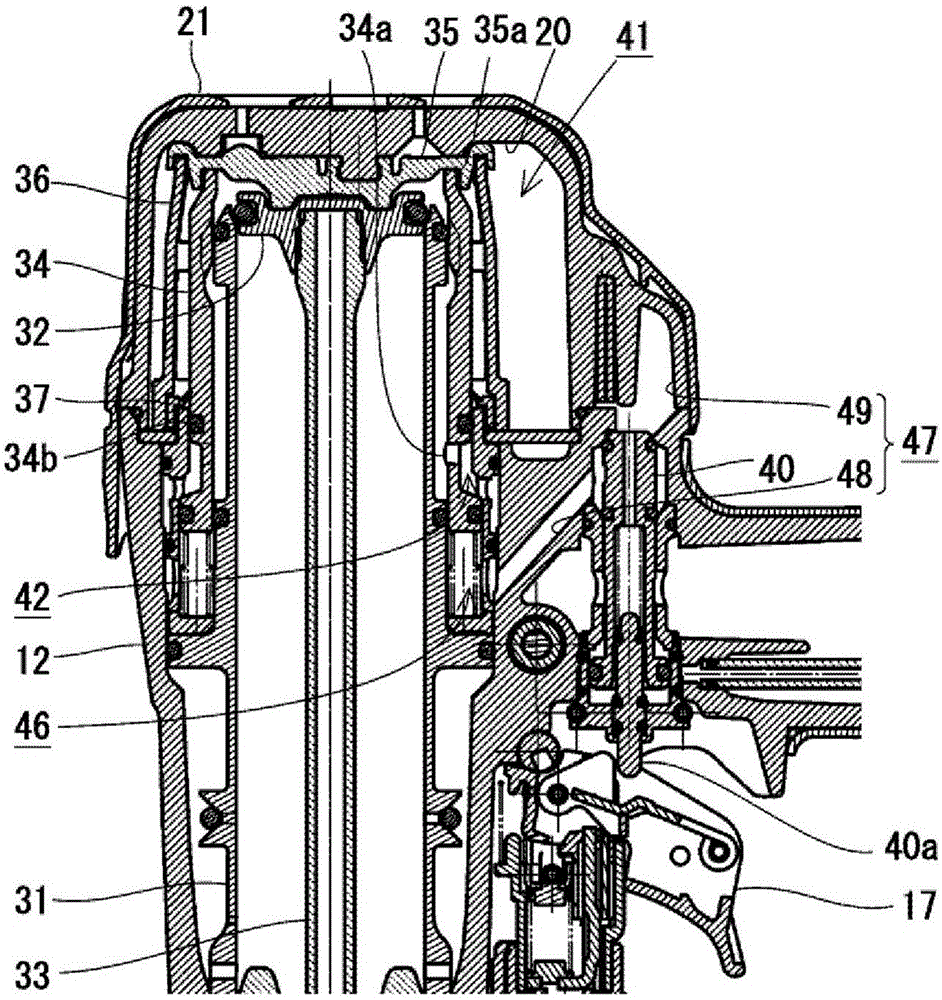

[0031] Such as figure 1 and figure 2 As shown, the tool body 11 includes: a body shell 12; a handle shell 16 which is connected to the body shell 12 substantially perpendicularly; and a head part 13, which is integrally fixed to the front end side of the body shell 12 (the direction in which fasteners are driven) ; And the cover housing 20, integrally fixed to the rear end side of the main body housing 12 (the direction opposite to the driving direction of the fastener).

[0032] Such as figure 2 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com