Guide rail type assembling frame body structure attached with lifting scaffold

A technology of attaching lifting and scaffolding, which is applied in the direction of scaffolding supported by house structure, house structure support, house structure support, etc., can solve the problems of adding scaffolding, difficulty, and single size and structure of the bottom truss, so as to reduce the moment of inertia, improve stability, The effect of mitigating the effects of dynamic loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

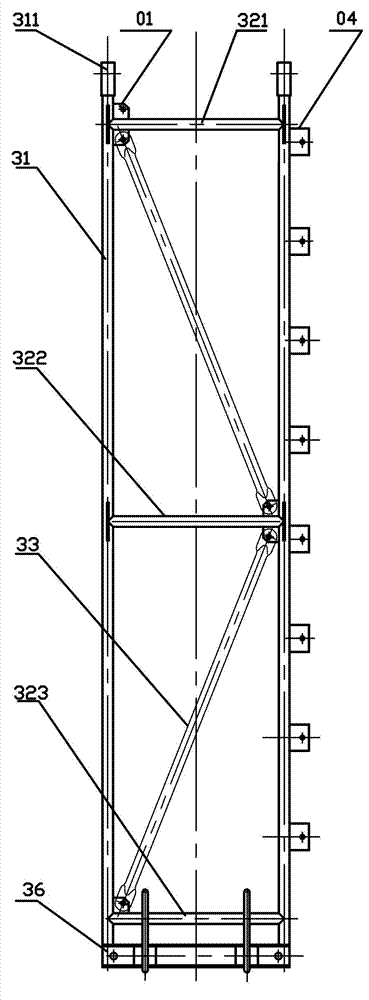

[0059] In this embodiment of the guide rail-attached scaffold assembly frame structure, the main column and the truss frame are assembled by rods, frames and connectors.

[0060] In this example, the rod and frame are made of an aluminum alloy tube with an outer diameter of φ48mm and a wall thickness of 3.5mm.

[0061] The connecting bolts used in this example are all M16 bolts.

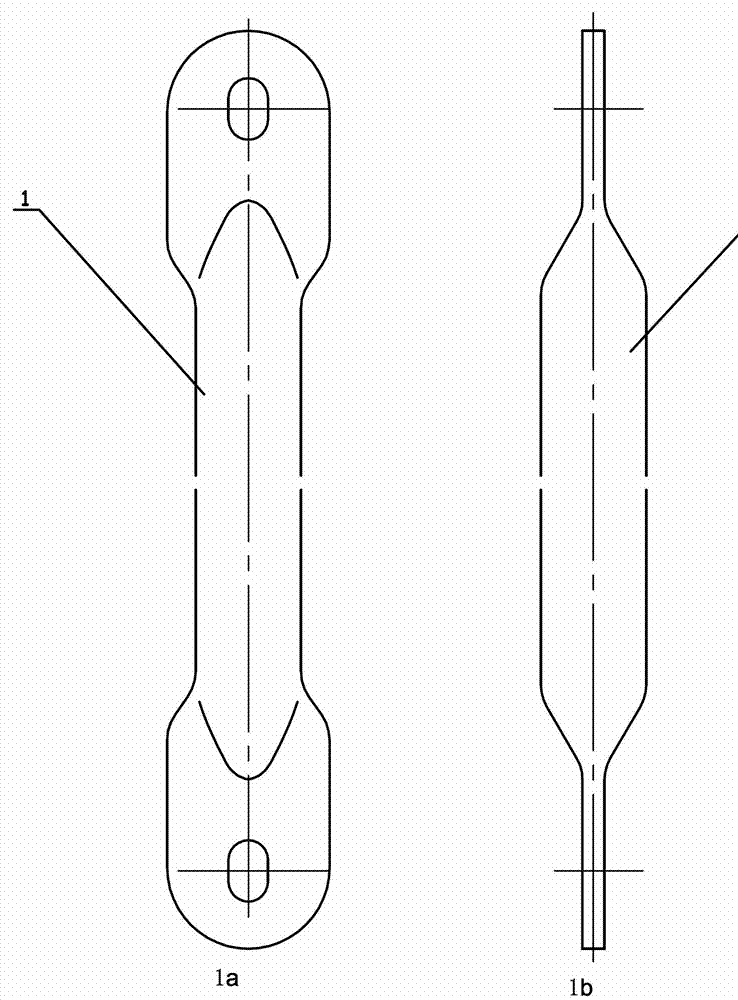

[0062] Rod 1 such as figure 1 as shown, figure 1 1a is the front view of the bar, and 1b is the side view of the bar. The two ends of the bar 1 are stamped into a plate with a width of 72mm to 74mm. There is a longitudinal long hole 18mm×22mm in the center of the plate. Symmetry, front and rear symmetry. Divided into connecting rod 11, main column horizontal tie rod 34, main column diagonal tie rod 33, main column side tie rod 35 and bottom truss horizontal tie rod 24, bottom truss diagonal tie rod 23, bottom truss side tie rod 25 according to length.

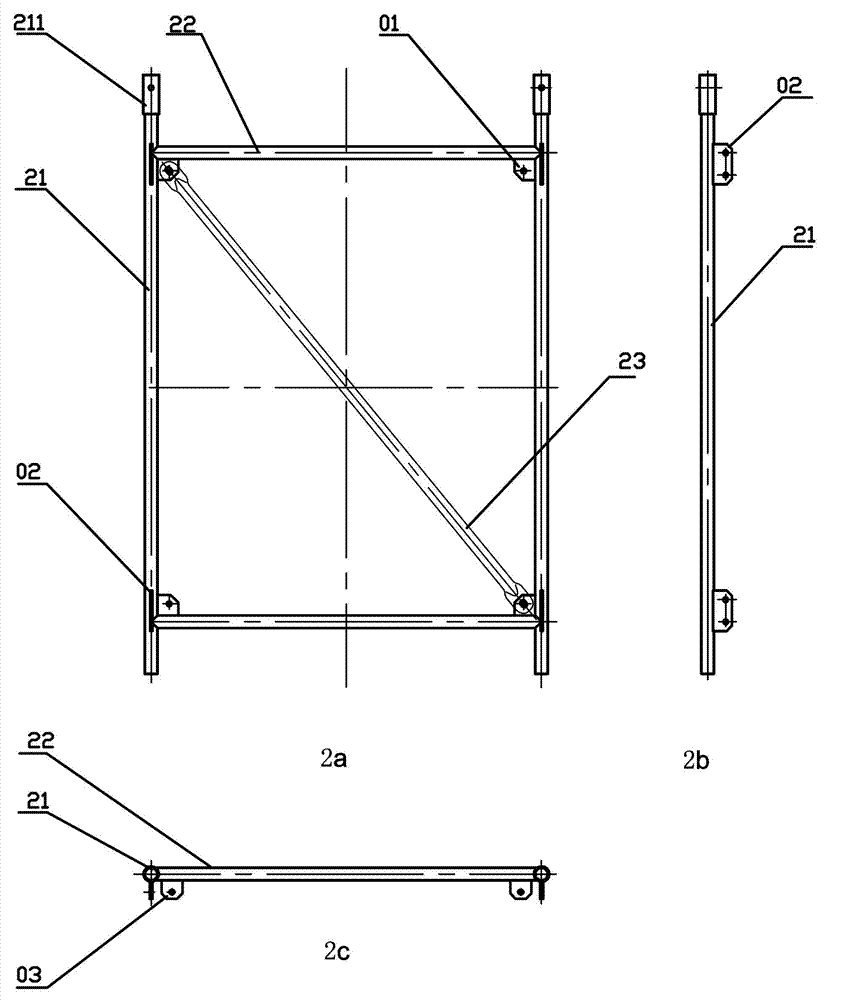

[0063] The frame parts are divided into bot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com