Application of high-toughness low-expansion zinc-based wear-resisting alloy for production of bearing cage

A bearing retainer, wear-resistant alloy technology, applied in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problem that the processing performance is not as good as steel, etc., and achieve the reduction of specific gravity, good oil immersion, excellent wear resistance and strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

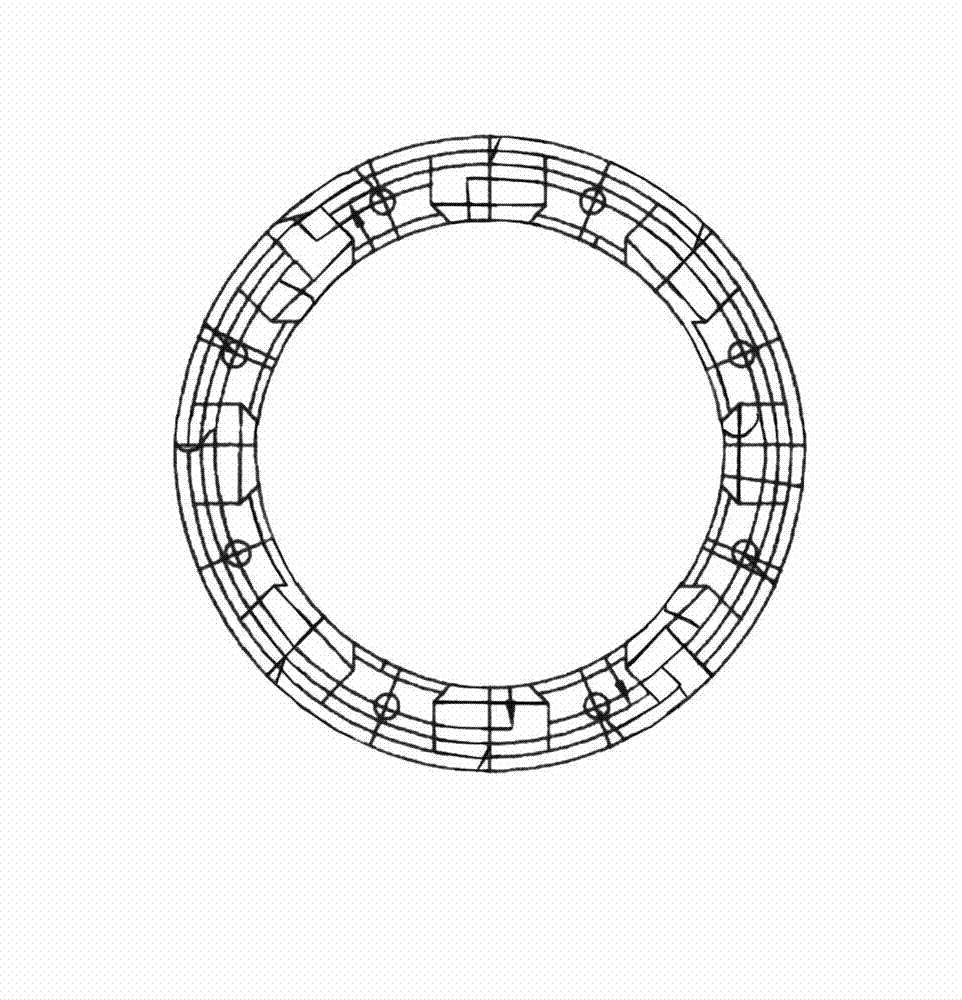

[0009] As shown in the figure, the application of the high-strength, toughness and low-expansion zinc-based wear-resistant alloy of the present invention as the production of the bearing retainer, the weight ratio of its raw material composition is: zinc is 55-65%, aluminum is 20-30%, and the intermediate alloy aluminum is 10-15%, cobalt aluminum is 1-2%.

[0010] The production method of the bearing retainer is that the above-mentioned materials are melted, cast into a mold, and then finished to obtain a high-strength, tough, low-expansion zinc-based wear-resistant alloy bearing retainer.

[0011] Said application is the production of high-strength, toughness and low-expansion zinc-based wear-resistant alloy as a bearing retainer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com