Anti-ice paint and preparation method thereof

An anti-ice and snow coating and coating technology, applied in the coating and other directions, can solve the problems of incompatibility, limited use range, weak adhesion, etc., and achieve the effect of good adhesion, good hydrophobicity, and maintaining flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

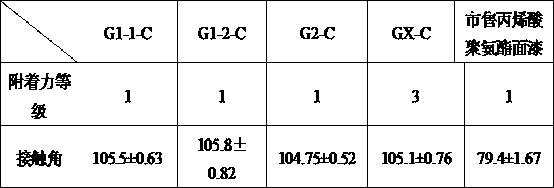

Examples

Embodiment 1

[0018] (1) Preparation of polyacrylate grafted PDMS copolymer containing POSS.

[0019] Take 12.5g of PDMS monomer with a number average molecular weight of 10,000, 28g of toluene, and 7g of tetrahydrofuran, stir in a 250ml glass reactor under nitrogen protection for half an hour, and mix well; slowly add 7.5g of methyl methacrylate, butyl acrylate, and Ester 2.5g, the mixed solution that toluene 24g, tetrahydrofuran 6g, azobisisobutyronitrile 0.082g are formed and the mixed solution that is made up of 1.25g of hydroxyethyl methacrylate, POSS monomer 1.25g, toluene 8g, tetrahydrofuran 2g; React at 65°C for 24 hours; slowly add the obtained reactant to a large amount of mixed solution of n-hexane and ethanol with a volume ratio of 1:2 for precipitation, filter the obtained precipitate, and dry to constant weight to obtain polyacrylate grafted PDMS copolymer containing POSS thing.

[0020] (2) Preparation of paint

[0021] Take 10g of the POSS-containing polyacrylate grafted P...

Embodiment 2

[0023] (1) Preparation of polyacrylate grafted PDMS copolymer containing POSS.

[0024] Take 7.5g of PDMS monomer with a number average molecular weight of 10000, 16g of toluene and 4g of tetrahydrofuran in a 250ml glass reactor under nitrogen protection and stir for half an hour to mix well; slowly dropwise add 7.5g of methyl methacrylate, butyl acrylate 2.5g, toluene 24g, tetrahydrofuran 6g and the mixed solution that dibenzoyl peroxide 0.12g form and the mixed solution that is made up of hydroxyethyl methacrylate 1.25g, POSS monomer 1.25g, toluene 8g and tetrahydrofuran 2g; Reaction at ℃ for 24 hours; slowly add a large amount of the reactant to a mixed solution of n-hexane and ethanol with a volume ratio of 1:2 for precipitation, filter the obtained precipitate, and dry to constant weight to obtain a polyacrylate grafted PDMS copolymer containing POSS .

[0025] (2) Preparation of paint.

[0026] Get 10g of the above-mentioned prepared polyacrylate grafted PDMS copolymer...

Embodiment 3

[0028] (1) Preparation of polyacrylate grafted PDMS copolymer containing POSS.

[0029] Take 12.5g of PDMS monomer with a number average molecular weight of 5000, 28g of benzene, and 7g of tetrahydrofuran in a 250ml glass reactor, stir for half an hour under nitrogen protection, and mix well; slowly dropwise add 7.5g of methyl methacrylate, butyl acrylate A mixed solution consisting of 2.5 g of ester, 24 g of benzene, 6 g of tetrahydrofuran, and 0.082 g of azobisisobutyronitrile and a mixed solution of 1.25 g of hydroxyethyl methacrylate, 1.25 g of POSS monomer, 8 g of benzene, and 2 g of tetrahydrofuran; React at 65°C for 24 hours; slowly add the obtained reactant to a large amount of mixed solution of n-hexane and ethanol with a volume ratio of 1:2 for precipitation, filter the obtained precipitate, and dry to constant weight to obtain polyacrylate grafted PDMS copolymer containing POSS things.

[0030] (2) Preparation of paint

[0031] Take 10g of the POSS-containing poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com