Flame-retardant natural fiber reinforced polylactic acid composite material and preparation method thereof

A natural fiber and composite material technology, applied in the field of materials, can solve the problems of deterioration of the interface between ramie fiber and polylactic acid, and poor bonding between polylactic acid and ramie fiber interface, and achieve simple and effective preparation methods, good flame retardancy and mechanical properties, The effect of mild process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

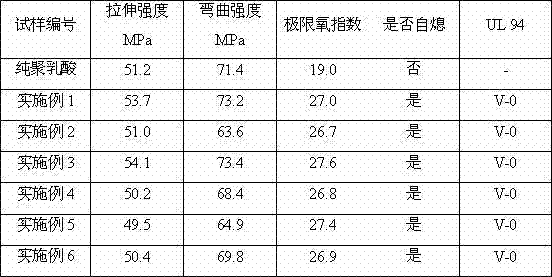

Examples

Embodiment 1

[0038] (1) Polylactic acid, jute yarn, functional flame retardant DOPO, antioxidant tris(2,4-di-tert-butylphenyl) phosphite, nano-montmorillonite, anti-dripping agent polytetrafluoroethylene Ethylene was vacuum dried at 70°C for 20 hours to remove moisture;

[0039] (2) Take the dry 498.5g polylactic acid obtained in step (1), 0.5g nano-montmorillonite, 0.5g tris(2,4-di-tert-butylphenyl) phosphite, and 0.5g polytetrafluoroethylene in Mix uniformly at 70° C. in a high-speed mixer to obtain a mixed material. Then put it into a twin-screw extruder for extrusion, the product is cooled, pelletized, and dried, the screw speed is 100 rpm, and the reaction extrusion temperature is 180°C.

[0040] (3) Add 100g of jute fiber and 10g of flame retardant into 500ml of ethanol, soak for 1 hour, take out the jute fiber, and dry at 50°C for 30 hours.

[0041] (4) Add 450g of the mixture obtained in step (2) and 50g of the jute fiber obtained in step (3) into a twin-screw extruder for extrus...

Embodiment 2

[0043] (1) Vacuum dry polylactic acid, hemp continuous long fiber, flame retardant, antioxidant phenylene diisodecyl phosphite, nano-montmorillonite, and anti-dripping agent polytetrafluoroethylene at 60°C for 18 hours, respectively, to remove moisture;

[0044] (2) Take 405g of dry polylactic acid obtained in step (1), 75g of nano-montmorillonite, 15g of phenylene diisodecyl phosphite, and 5g of polytetrafluoroethylene and mix them uniformly in a high-speed mixer at 60°C to obtain a mixed material. Then put it into a twin-screw extruder for extrusion, the product is cooled, pelletized, and dried, the screw speed is 150 rpm, and the reaction extrusion temperature is 185°C.

[0045] (3) Add 100g of hemp fiber and 3g of flame retardant into 500ml of ethanol, soak for 10 hours, take out the hemp fiber, and dry at 130°C for 1 hour.

[0046] (4) Add 100g of the mixture obtained in step (2) and 1g of hemp fiber in step (3) to a twin-screw extruder for extrusion. The product is cool...

Embodiment 3

[0048](1) Vacuum dry polylactic acid, bamboo fiber with an aspect ratio of 5, flame retardant, antioxidant tris(nonylphenyl phosphite), carbon nanotubes, and anti-dripping agent polytetrafluoroethylene at 60°C 20 hours to remove moisture;

[0049] (2) Take 445g of dry polylactic acid obtained in step (1), 5g of carbon nanotubes, 30g of tris(nonylphenyl phosphite), and 20g of polytetrafluoroethylene and mix them uniformly in a high-speed mixer at 70°C to obtain a mixed material . Then put it into a twin-screw extruder for extrusion, the product is cooled, pelletized, and dried, the screw speed is 50 rpm, and the reaction extrusion temperature is 175°C.

[0050] (3) Add 100g of bamboo fiber and 20g of flame retardant into 500ml of ethanol, soak for 5 hours, take out the bamboo fiber, and dry at 100°C for 5 hours.

[0051] (4) Add 100g of the mixture obtained in step (2) and 30g of bamboo fiber in step (3) to a twin-screw extruder for extrusion. The product is cooled, pelletize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com