Turning and boring dual-purpose numerical control woodworking lathe

A woodworking lathe, dual-purpose technology, applied in wood processing appliances, manufacturing tools, multi-purpose machinery, etc., can solve problems such as low production efficiency and poor finish, and achieve high production efficiency, high processing accuracy, and good finish.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

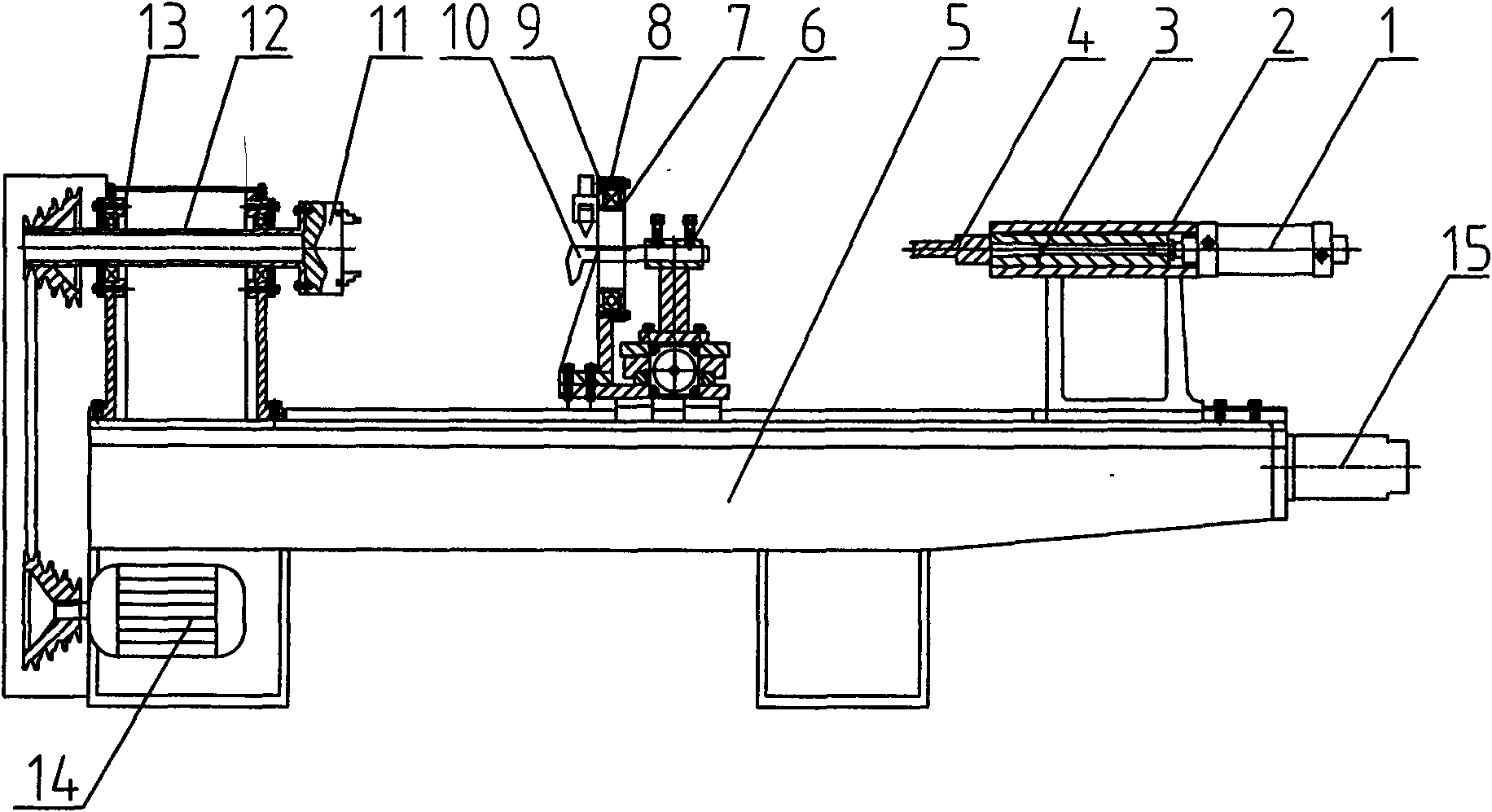

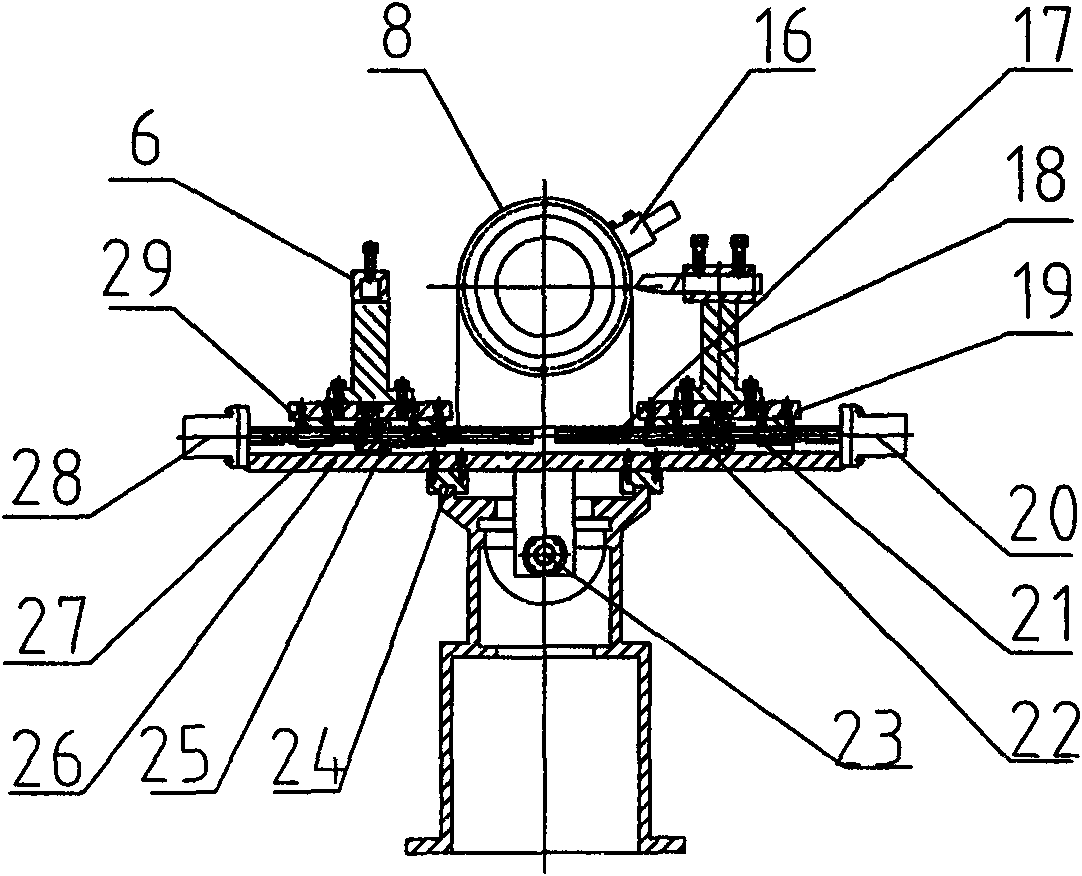

[0016] Such as figure 1 , figure 2 Shown is a dual-purpose CNC woodworking lathe for turning and boring, which includes a body 5, a headstock 13 is installed at one end of the upper part of the body 5, and a spindle 12 is installed on the headstock 13, and one end of the spindle 12 is connected to the body 5 through a transmission mechanism. The lower main motor 14 is connected, the other end of the main shaft 12 is equipped with a four-jaw self-centering chuck 11, the other end of the upper part of the fuselage 5 has a tailstock 2, and the rear of the tailstock 2 is equipped with a tailstock cylinder 1 , the middle part of the tailstock 2 is equipped with a tailstock sliding sleeve 3, and the front end of the tailstock sliding sleeve 3 is equipped with a tailstock thimble 4; Supporting plate 26, main screw 23 is housed between the lower supporting plate 26 and the fuselage 5, the outer end of main leading screw 23 is connected with main screw motor 15, and following tool re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com