Preparation method of Bifidobacterium microcapsules

A technology of bifidobacteria and composite microcapsules, which is applied in the field of preparation of bifidobacteria microcapsules, can solve the problems of high production cost and poor operability, and achieve reduced production costs, high survival rate, and improved bioavailability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

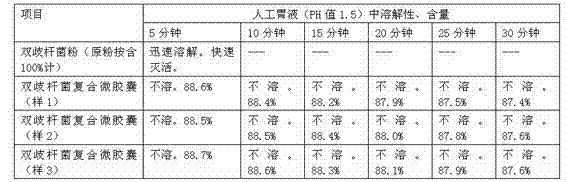

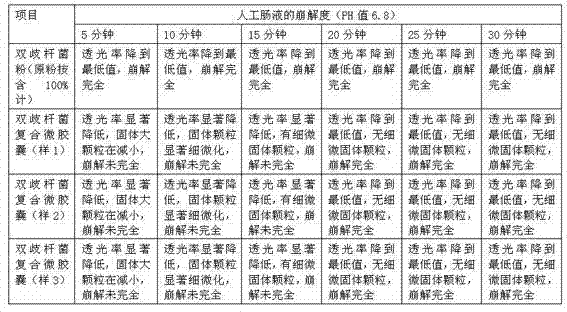

Examples

Embodiment 1

[0030] A preparation method of bifidobacterium composite microcapsules, the steps are as follows:

[0031] Step 1: Preparation of composite bacterial suspension

[0032] At 30°C, in 100ml of distilled water, add 3g of bifidobacterium strains, 1g of Chinese yam powder that has completely passed through a 100-mesh nylon sieve, and 1g of stachyose that has completely passed through a 100-mesh nylon sieve, stir well, and use a 24-mesh Synthetic fiber sieve filter, the filtrate is the bacterial suspension, ready for use;

[0033] Step 2: Dissolution of wall material

[0034] Add 5g pectin, 1g bitter almond extract, and 1g amomum extract to 100ml distilled water, swell with distilled water at 30°C for 1.5 hours, stir to dissolve, place at 30°C for 6 hours, and ultrasonically remove bubbles, spare;

[0035] Step 3: Add 3g of sodium alginate, 1g of orange peel extract, and 1g of gardenia extract to 100ml of distilled water, swell with distilled water at 30°C for 1.5 hours, ...

Embodiment 2

[0040] Embodiment 2: same as embodiment 1 process, different parts are as follows:

[0041] Step 1: Preparation of composite bacterial suspension

[0042] At 20°C, in 100ml of distilled water, add 5g of bifidobacterium strains, 0.5g of Chinese yam powder that has completely passed through a 100-mesh nylon sieve, and 0.5g of stachyose that has completely passed through a 100-mesh nylon sieve, stir well, and use Filter through a 24-mesh synthetic fiber screen, and the filtrate is the bacterial suspension, which is ready for use;

[0043] Step 2: Dissolution of wall material

[0044] Add 12g of pectin, 0.5g of bitter almond extract, and 0.5g of amomum extract per 100ml of distilled water, swell with distilled water at 20°C for 1 hour, stir to dissolve, and place at 30°C for 5 hours , ultrasonically remove air bubbles, set aside;

[0045] Step 3: Add 5g of sodium alginate, 0.5g of orange peel extract, and 0.5g of gardenia extract per 100ml of distilled water, swell with dis...

Embodiment 3

[0046] Embodiment 3: identical with the technological process of embodiment 1, difference is as follows:

[0047] Step 1: Preparation of composite bacterial suspension

[0048] At 30°C, add 4g of bifidobacterium strains, 0.7g of Chinese yam powder that has completely passed through a 100-mesh nylon sieve, and 0.7g of stachyose that has completely passed through a 100-mesh nylon sieve into 100ml of distilled water, stir well, and use Filter through a 24-mesh synthetic fiber screen, and the filtrate is the bacterial suspension, which is ready for use;

[0049] Step 2: Dissolution of wall material

[0050] According to the ratio of adding 8g pectin, 0.7g bitter almond extract, and 0.7g amomum extract per 100ml of distilled water, add the above three kinds into distilled water, swell with distilled water at 30°C for 1.5 hours, stir to dissolve, Place at 30°C for 6 hours, ultrasonically remove air bubbles, and set aside;

[0051] Step 3: According to the ratio of adding 4g s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com