Method for manufacturing separator, separator manufactured by the method and method for manufacturing electrochemical device including the separator

一种隔板、设备的技术,应用在电化学发生器、最终产品制造、可持续制造/加工等方向,能够解决粘合性降低、电极粘合性降低、减少等问题,达到增强粘合性、高粘合强度、提高稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] cyanoethylpullulan as the first binder polymer and polyvinylidene fluoride-co-hexafluoropropylene (PVdF-HFP) as the second binder polymer with a weight ratio of 2:10 ) polymer mixture was dissolved in acetone at 50 °C for at least about 12 h to prepare a polymer solution. Add barium titanate (BaTiO 3 ) powder until the weight ratio of polymer mixture to inorganic powder reaches 10:90. After at least 12 hours, the inorganic particles were pulverized and dispersed using a ball mill to prepare a slurry. The inorganic particles of the slurry prepared in this way had an average particle diameter of 600 nm.

[0059] In addition, distilled water was used as a non-solvent for the second binder polymer.

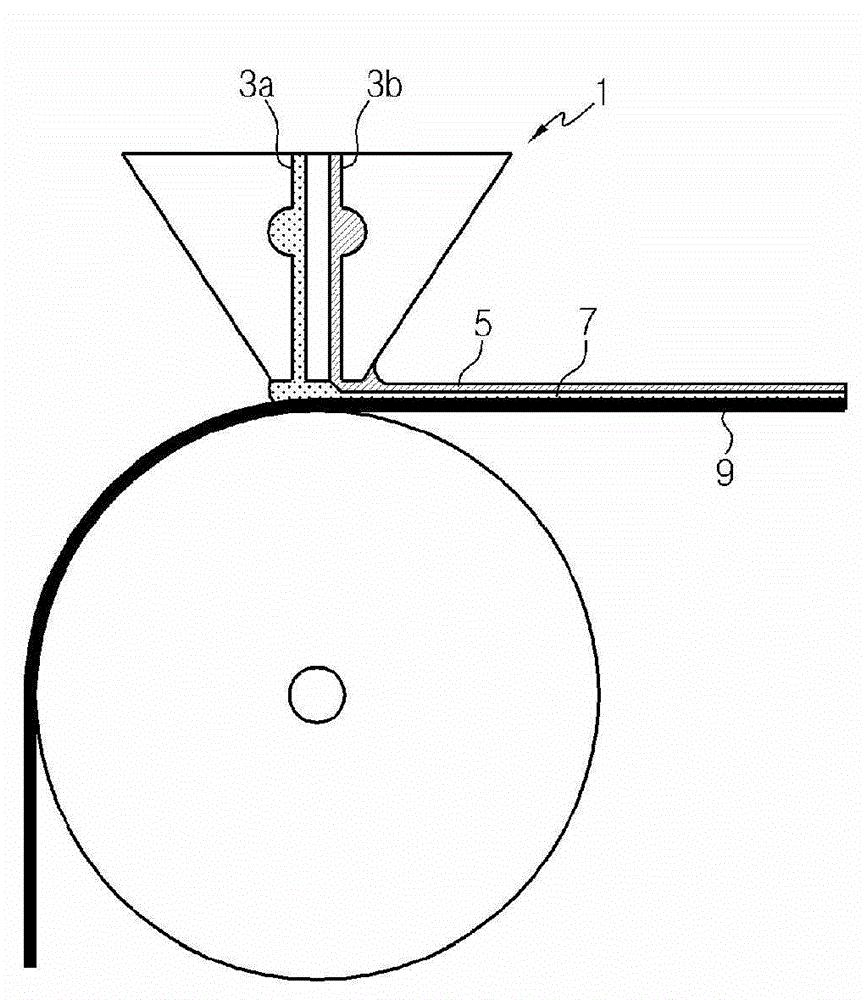

[0060] Pass the slurry and non-solvent prepared in this way through figure 1 The slot die shown in was continuously coated onto one side of a 12 μm thick porous polyethylene terephthalate film (45% porosity). The wet thicknesses of the slurry and non-solvent were adjusted ...

Embodiment 2

[0065] A separator was fabricated in the same manner as in Example 1, except that the kind of non-solvent was changed to a mixture of distilled water and methanol (5:5 (v / v)). The obtained separator was found to have a Gurley value of 367.6 sec / 100 mL and an adhesive strength of 9.81 gf / cm.

Embodiment 3

[0067] A separator was manufactured in the same manner as in Example 1 except that the kind of the first adhesive polymer was changed to cyanoacrylate. The obtained separator was found to have a Gurley value of 375.4 sec / 100 mL and an adhesive strength of 13.94 gf / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com