Thermoelectric generation module

A technology of thermoelectric power generation and electrodes, which is applied in the direction of thermoelectric devices, generators/motors, and parts of thermoelectric devices, etc. It can solve problems such as the increase in the resistance value of thermoelectric elements, the increase in the resistance value of the joint interface, and the decrease in the output power of thermoelectric modules.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

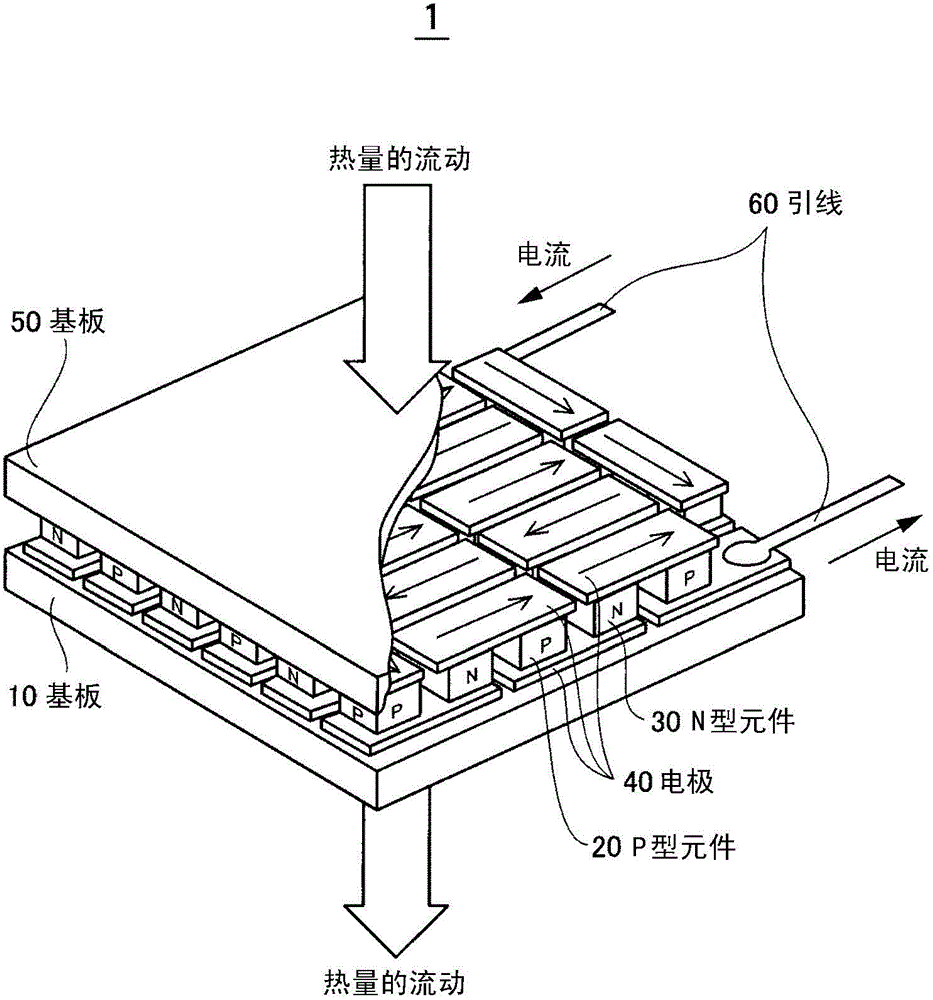

[0034] Hereinafter, for the embodiments of the present invention, while referring to the attached Figure 1 Explain in detail. It should be noted that the same reference numerals are assigned to the same structural elements, and explanations thereof will be omitted.

[0035] figure 1It is a perspective view showing the outline of a thermoelectric power generation module according to each embodiment of the present invention. In the thermoelectric power generation module 1, for example, a thermoelectric power generation element (P-type element) 20 formed of a P-type thermoelectric material is joined via an electrode 40 on a substrate (heat exchange substrate) 10 formed of an electrically insulating material such as ceramics, and A thermoelectric power generation element (N-type element) 30 formed of an N-type thermoelectric material forms a PN element pair. Furthermore, a substrate (heat exchange substrate) 50 made of an electrically insulating material is disposed on the pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com