Flat heat exchange tube of heat exchanger and heat exchanger of flat heat exchange tube

A technology of heat exchange tubes and heat exchangers, which is applied in evaporators/condensers, tubular elements, heat exchange equipment, etc., and can solve problems such as insufficient channel arrangement, few channels, and unfavorable heat exchange.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Below in conjunction with the preferred embodiments, the specific implementation, features and effects provided by the present invention are described in detail as follows; for the purpose of simplicity and clarity, the description of known technologies is appropriately omitted below to avoid unnecessary details Affect the description of this technical solution.

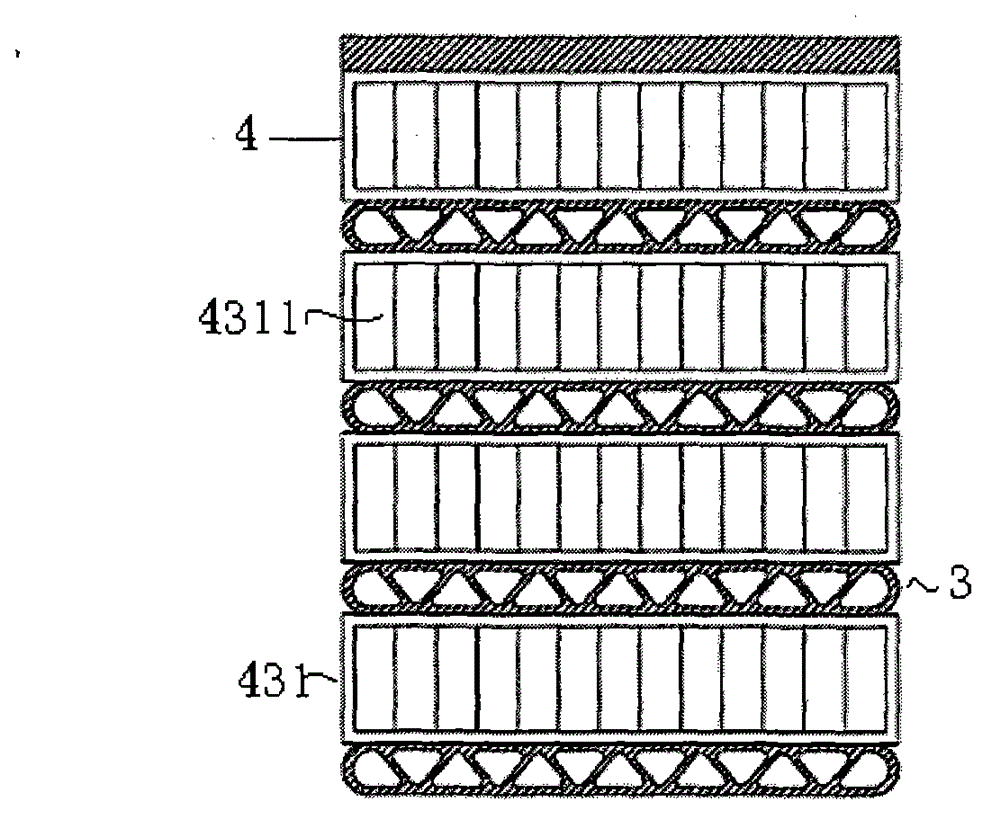

[0069] see Figure 1-8 As shown, a flat tube structure of a heat exchanger and its heat exchanger include a first liquid collection pipe 1, a second liquid collection pipe 2, and a plurality of devices installed between the two liquid collection pipes to accommodate refrigerant passage. a flat heat exchange tube 3, and a fin strip 4 installed between the flat heat exchange tubes for heat dissipation;

[0070] The flat heat exchange tubes 3 are parallel to each other and are separated from each other by the same predetermined distance. The two ends of the flat heat exchange tubes are provided with tooling shri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com