Integral embossing roller and manufacturing method thereof

An integral, roll technology, applied in the field of embossing rolls, can solve the problems of torsional deformation, pattern dislocation, etc., and achieve the effect of uniform spacing, easy assembly, and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the drawings. The enumerated embodiments can make those skilled in the art better understand the present invention, but do not limit the present invention in any form

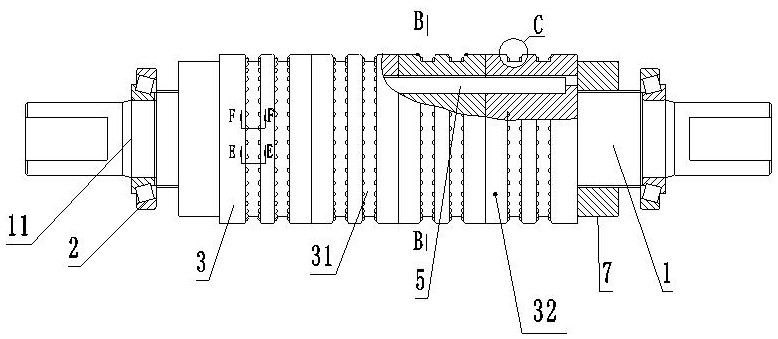

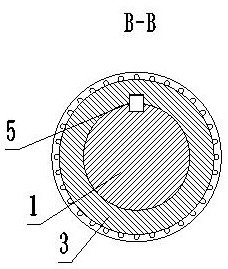

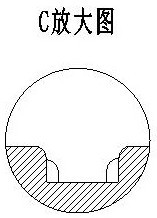

[0025] like Figure 6-10 As shown, an integral embossing roll is improved on the basis of the prior art. The roll is composed of a central shaft and a bearing. The two ends of the central shaft 1 are roll necks 11, and the roll neck is used to install the bearing 2. , the surface processing of the middle part of the central shaft has surface processing with rolling grooves 31, and the multiple rolling grooves are distributed at equal intervals, and the adjacent rolling grooves are separated by cylindrical sections 32. The present invention integrates the central shaft and the insert into one, improves it into an integral type, cancels the insert, flat key and nut, and directly processes rolling grooves on the surface of the centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com