Vertical heat exchange type ventilator

A ventilating device, vertical technology, applied in the direction of household heating, heating method, household heating, etc., can solve the problem of unable to meet the installation environment or residential design, and achieve the effect of volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

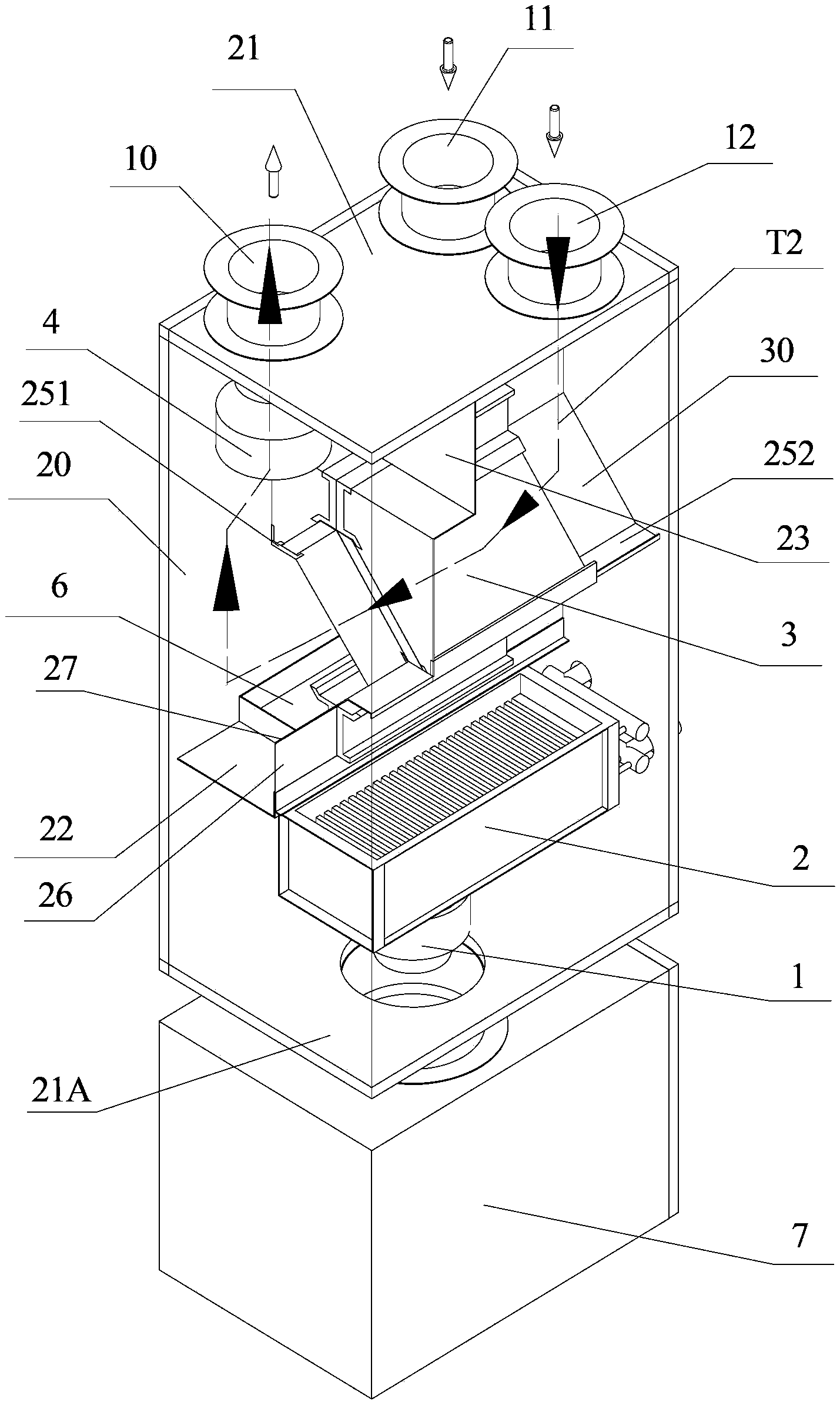

[0027] specific reference figure 1 , the planar isolation plate 22 is located inside the housing and is parallel to the top plate 21 . In the space surrounded by the side plate 20, the top plate 21 and the isolation plate 22, the heat exchanger 3 with a square section, its left corner abuts against the left side of the side plate 20 (the side where the air outlet 10 is located); The line abuts against the right side of the side plate 20 (the side where the return air outlet 12 is located). exist figure 1 In the above, the abutment between the corner line of the heat exchanger 3 and the side plate 20 refers to the abutment through the air duct plate (details will be described later). If necessary, the vertex line of the heat exchanger 3 may be directly in contact with the side plate 20 .

[0028]In the manner of connecting with the four corners of the square section of the heat exchanger 3, a vertical first air channel plate 23 is provided between the top plate 21 and the to...

no. 2 example

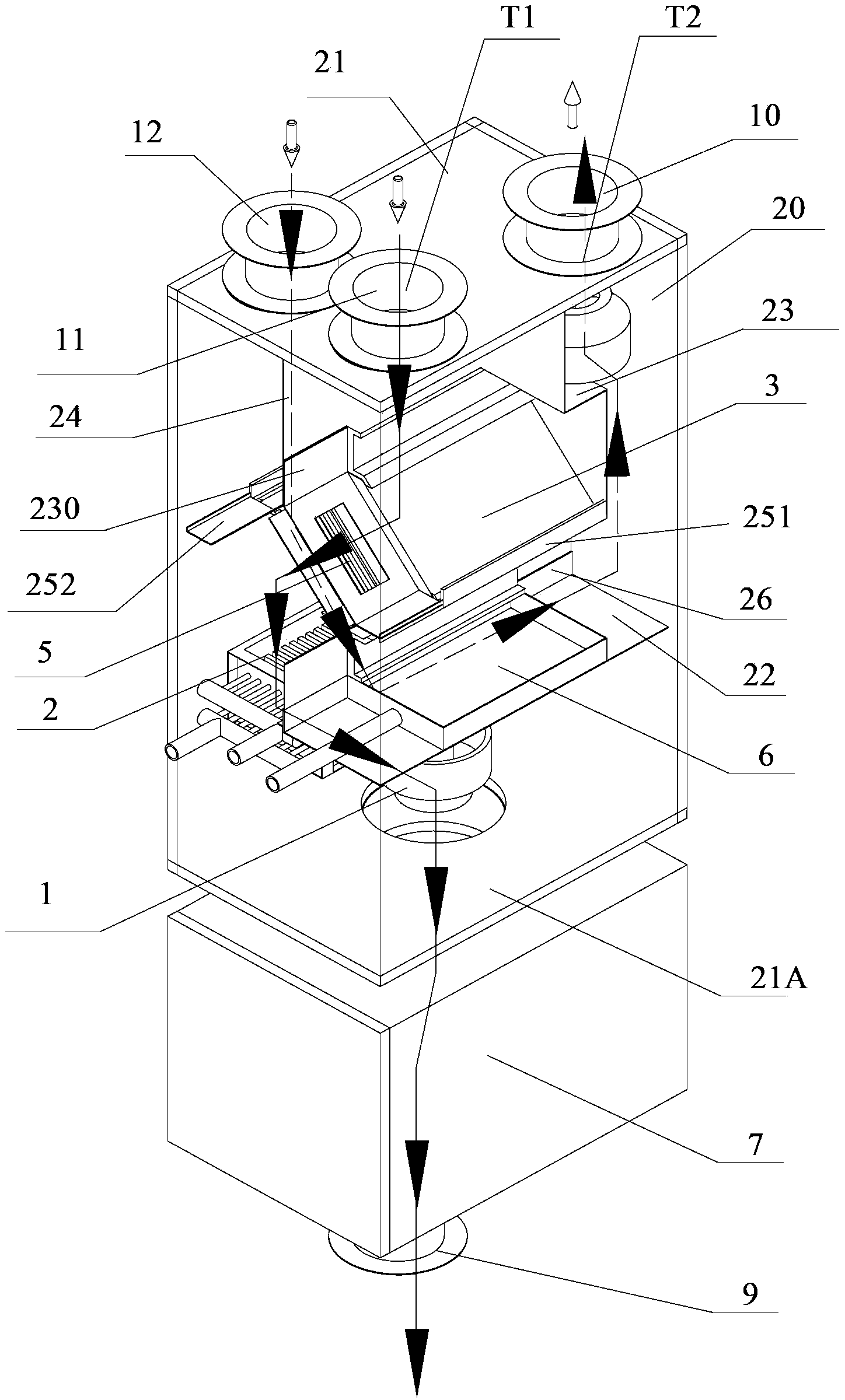

[0051] Figure 4 A structural diagram of a second embodiment of the present invention is schematically shown. Here, the structure of the second embodiment that is different from the first embodiment is mainly described, and the same or similar parts will not be repeated here.

[0052] Such as Figure 4 As shown, the heat exchanger 3 in the second embodiment is connected to the front side plate of the housing, but not to the rear side plate. The air supply part provided on the isolation plate 22 is the air supply port 9 . The fourth air duct plate 252 is connected to the opposite front and rear side plates of the side plates; the third air duct plate 251 is only connected to the front side plate without extending to the rear side plate, and its length is consistent with the length of the heat exchanger 3 . The flow direction of the fresh air is shown by the solid arrow; the flow direction of the return air is shown by the hollow arrow.

[0053] The fresh air on one side of ...

no. 3 example

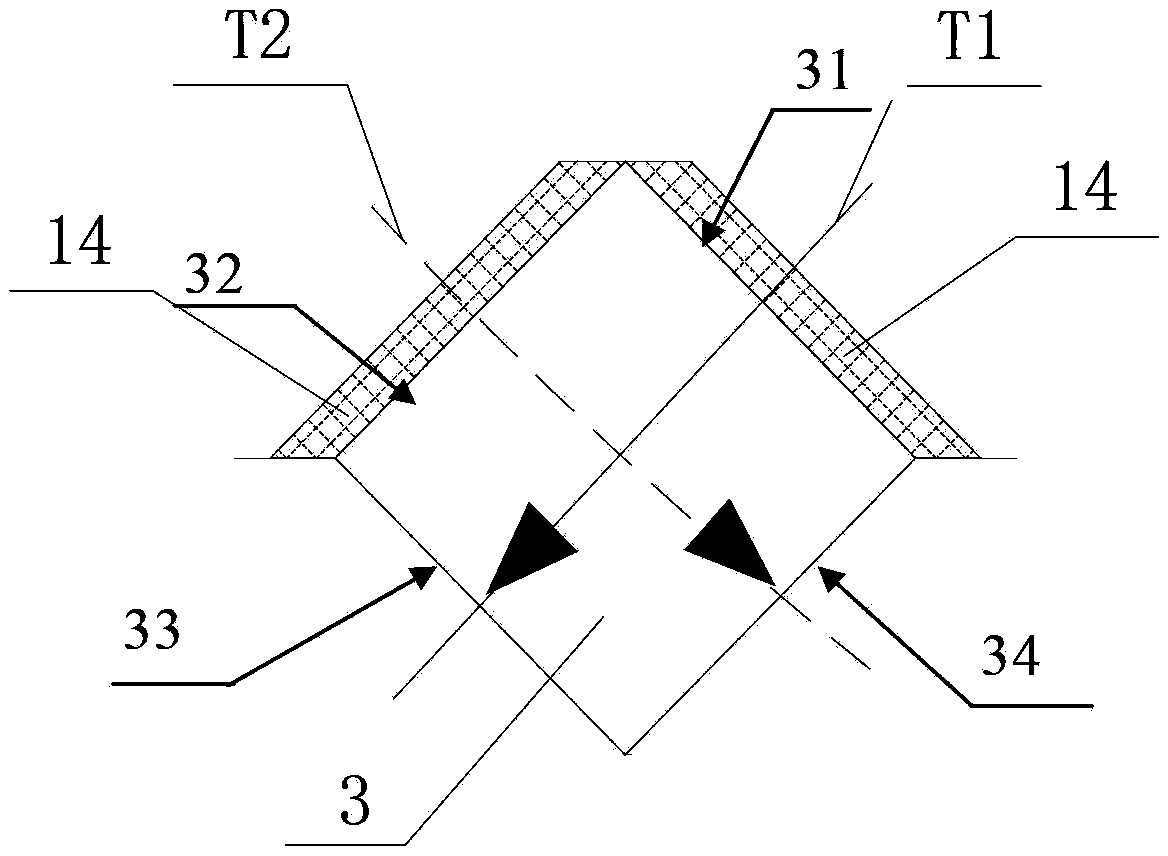

[0061] Figure 5 A third embodiment of the present invention is schematically illustrated. Here, the structure of the third embodiment that is different from the second embodiment is mainly described, and the same or similar parts will not be repeated here.

[0062] Such as Figure 5 As shown, the first air channel plate 23 is not connected to the opposite side portions of the side plate 20 , but extends from one side of the side plate 20 to the second air channel plate 24 . The first air duct plate 23 is located between the fresh air port 11 and the return air port 12, and the air outlet 10, and connects the side plate 20 and the top plate 21, and extends downward from the top plate 21 to the fresh air inlet surface 31 and the heat exchanger 3. Air return air intake surface 32 . The first air duct plate 23 is on the same plane as the end surface of the heat exchanger 3 not connected to the side plate 20 .

[0063] The second air channel plate 24 extends from one side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com