A high-moisture distiller's grain fuel direct-fired boiler system

A high-moisture, distiller's grains technology, applied in fuel supply, combustion method, combustion equipment, etc., can solve the problems of high operating cost, large floor space, large energy consumption, etc., to improve combustion efficiency, ensure complete combustion, and reduce the number of Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

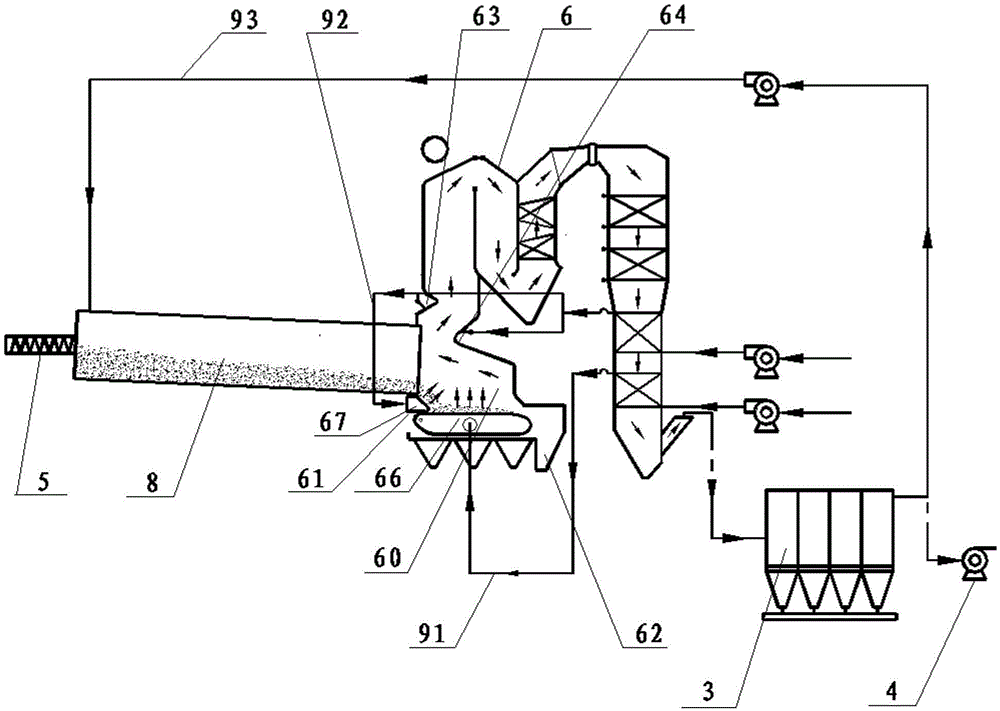

[0024] In order to enable those skilled in the art to better understand the technical solution of the present invention, its specific implementation will be described in detail below in conjunction with the accompanying drawings:

[0025] see image 3 , high-moisture distiller's grain fuel direct-fired boiler system, including screw conveyor 5, boiler 6, dust collector 7, dry gasification combustion device 8 and air distribution system, of which:

[0026] The boiler 6 comprises a furnace 60, a furnace feed opening 61 positioned at the bottom of the front side wall of the furnace, a furnace discharge port 62 positioned at the bottom of the rear side wall of the furnace, an upper tuyeres 63, 64 positioned at the front and rear side walls of the furnace, Furnace lower tuyeres 65 on the hearth floor, chain fire grate 66 located at the bottom of the furnace 60 and running through between the furnace feed port 61 and the furnace discharge port 62, and the water-cooled fire grate 67 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com