LED (Light-Emitting Diode) light source based on special module

A technology of LED light source and LED chip, applied in the field of LED lighting, can solve the problems of large light loss, complex process, messy lamps, etc., to achieve the effect of heat dispersion, simplified process, soft and uniform optical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

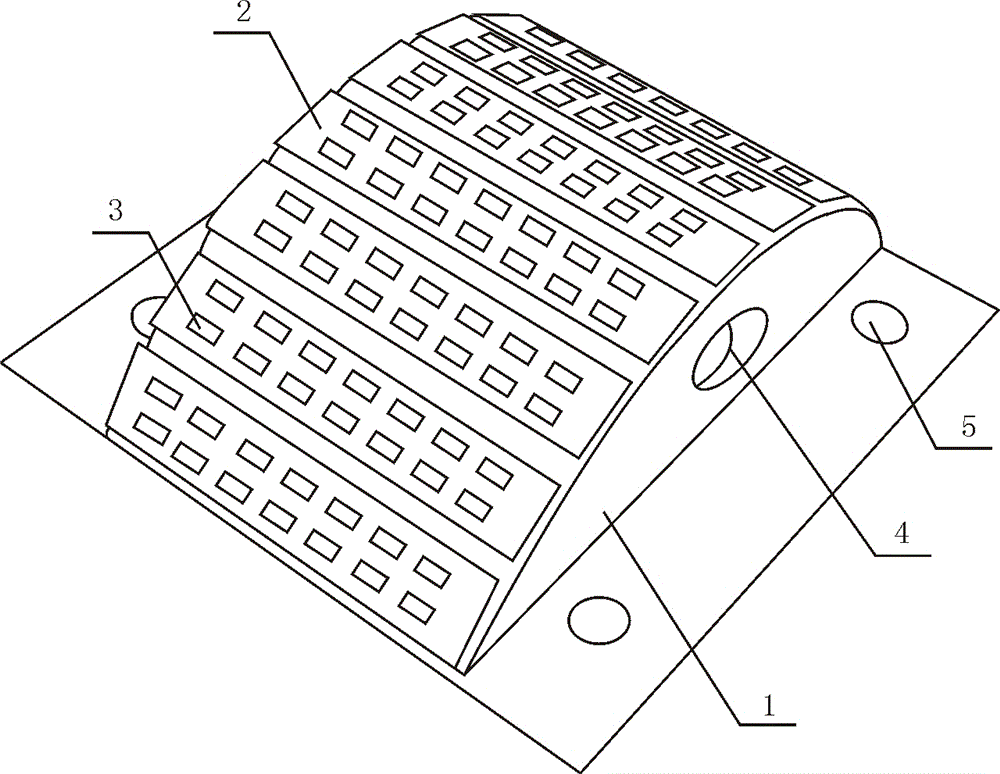

[0018] Such as figure 1 As shown, a LED light source based on a special-shaped module includes a solid metal module 1, the upper surface of the module 1 is a non-planar structure, and the upper surface of the module 1 is a cylindrical surface, a spherical surface, a polygonal cylinder surface or paraboloid. In this embodiment, the module 1 is semi-cylindrical, and its upper surface is a cylindrical surface. The module 1 is covered with a high thermal conductivity substrate 2 corresponding to its shape. The substrates 2 are rectangular, and two pairs are closely pasted on the upper surface of the module 1, so that the upper surface of the substrate 2 is also a non-planar structure. Alternatively, the base plate 2 covers the entire upper part of the module 1 as a whole. The substrate 2 includes a bottom layer of low thermal resistance, an insulating and heat-conducting layer, and an electrolytic copper foil layer laid sequentially from bottom to top. The electrolytic copper fo...

Embodiment 2

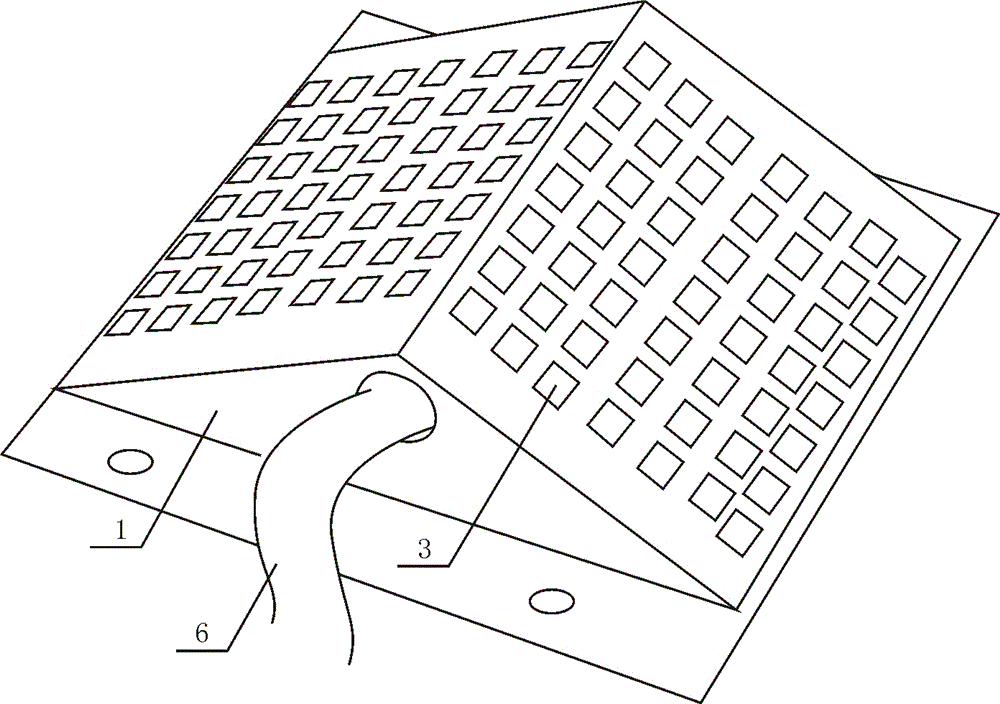

[0021] Such as figure 2 As shown, an LED light source based on a special-shaped module is different from Embodiment 1 in that the module 1 is a horizontal triangular prism. There are two substrates 2, both of which are rectangular, and are pasted on the upper surface of the module 1; or the substrate 2 covers the entire upper surface of the module 1 as a whole. The through hole 4 runs through the entire triangular prism, and a heat pipe 6 is arranged in the through hole 4 to quickly transfer the heat on the module 1 to the outside air through the heat pipe 6 .

Embodiment 3

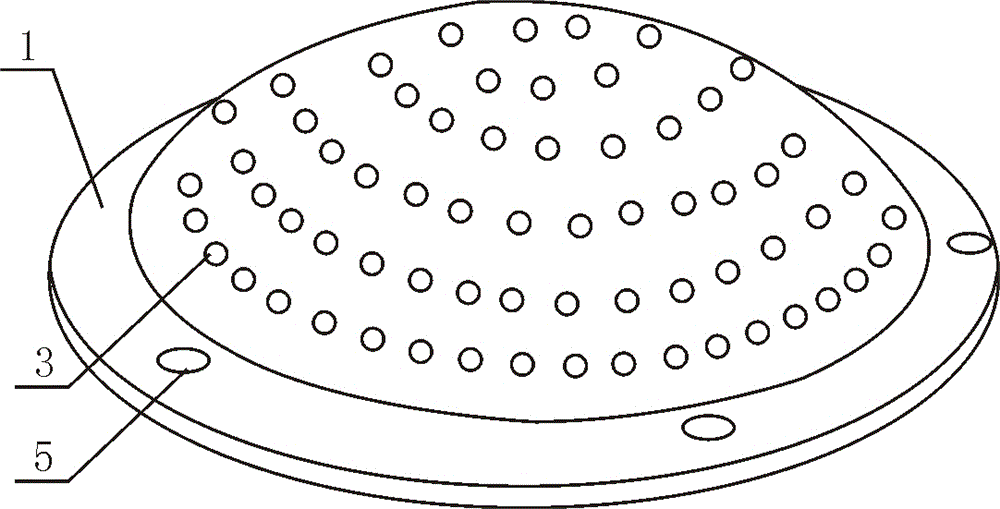

[0023] Such as image 3 As shown, an LED light source based on a special-shaped module is different from the first embodiment in that the upper surface of the module 1 is spherical. The bottom of the module 1 extends around to form a circle of edges, and the edges are provided with fixing holes 5 . The entire substrate 2 is attached to the upper surface of the module 1 .

[0024] This LED light source can be widely used in high-power street lamps and flood lamp series.

[0025] In short, there are two directions for the realization of LED high-power module light sources: one is to improve the substrate manufacturing process and make special-shaped substrates, and the investment in equipment improvement is small; the other is to improve the operation track of packaging machinery, which requires a large investment, but in terms of structure and performance , will be much better. Therefore, an ideal high-power LED light source is preferably formed by directly packaging a point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com